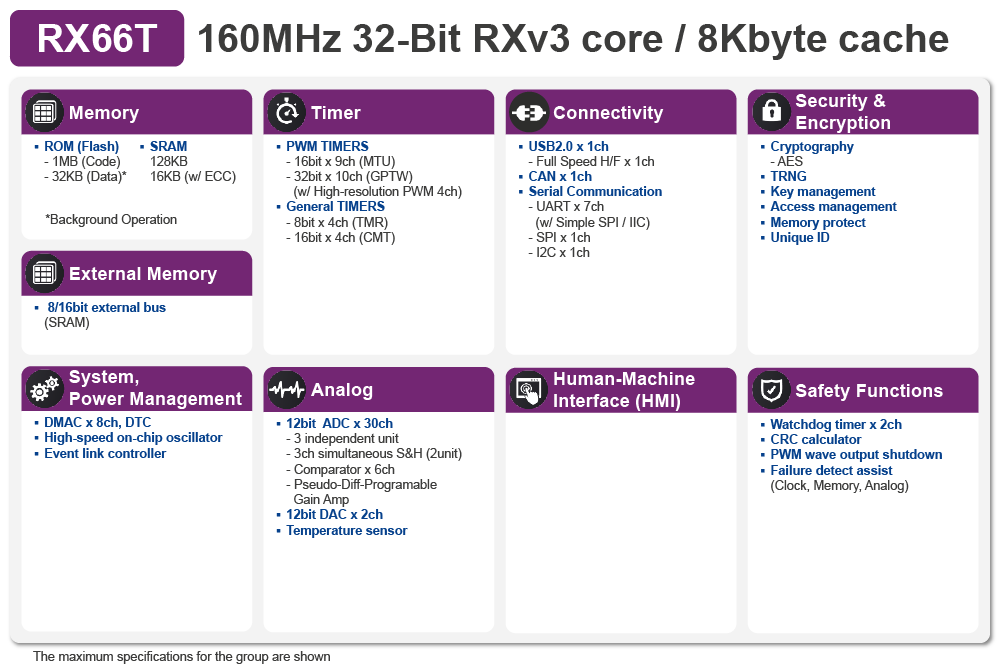

Features

- 160MHz RXv3 core (6.01 CoreMark/MHz*), single-precision FPU

- *Typical for RXv3 core

- Wide operating voltage range: 2.7V to 5.5V

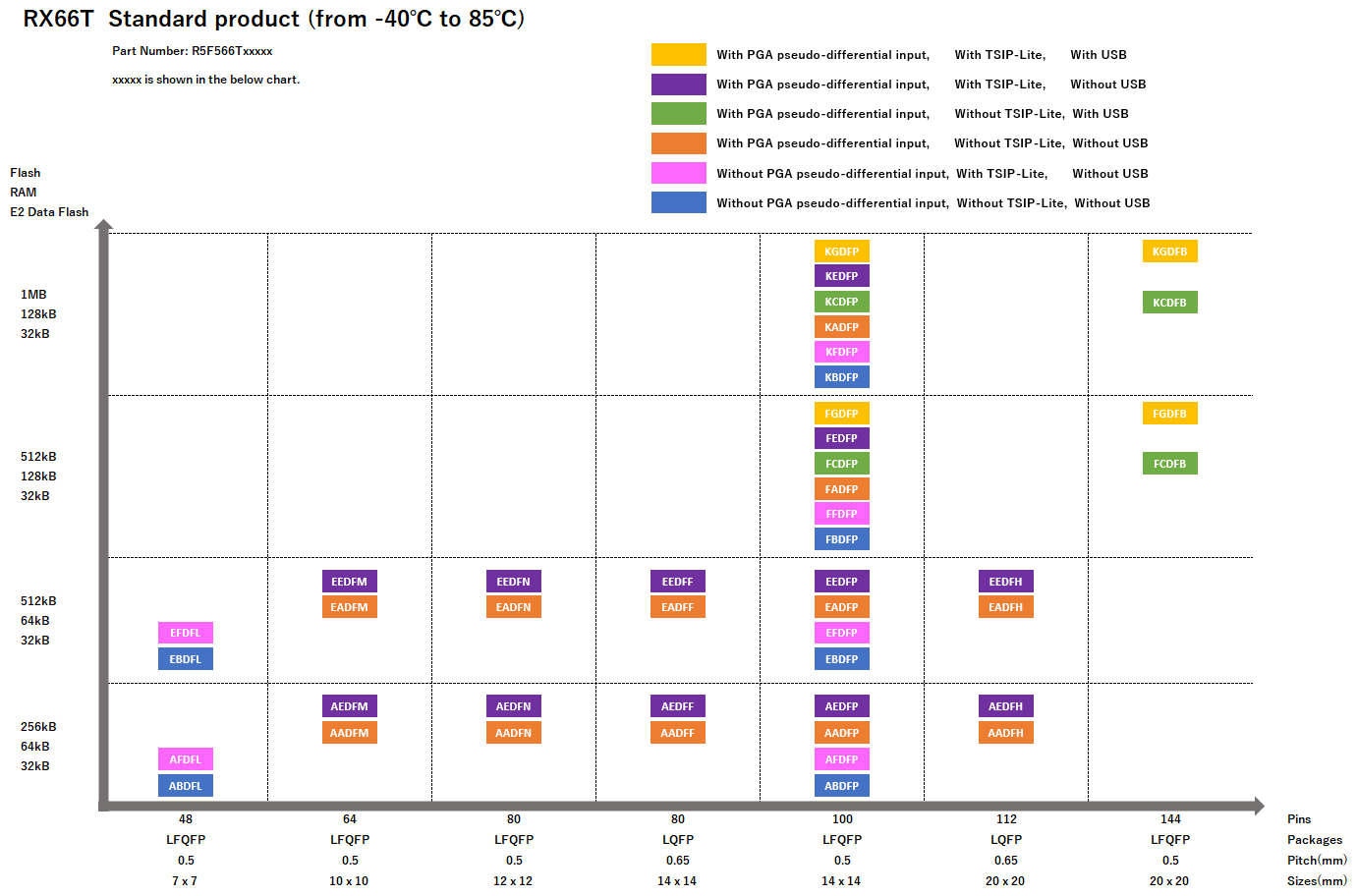

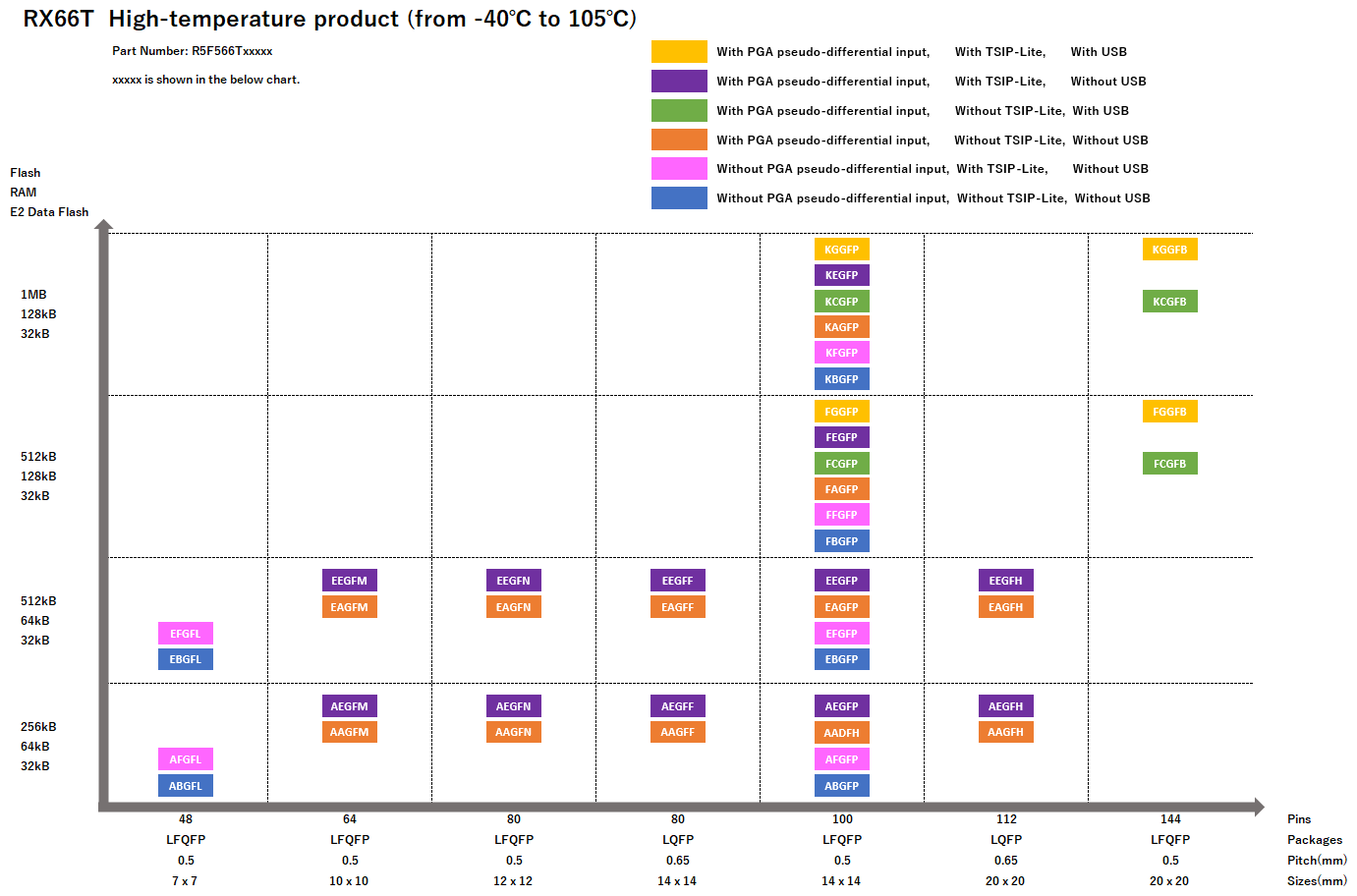

- Operating temperature: -40°C to 85°C or -40°C to 105°C

- Large-capacity memory: 1MB code flash, 128KB SRAM

- 32KB data flash that can store data like an EEPROM

- Diverse package lineup from 48 to 144 pins

- Up to 110 general-purpose I/O ports

- USB 2.0 Host/Function/OTG (supports full speed (12Mbps), low speed (1.5Mbps), and isochronous transfer)

- CAN (ISO 11898-1 compliant, up to 1Mbps transfer)

- Various other communication interfaces (SCI, IIC, RSPI, etc.)

- 160MHz PWM

- 4 channels for 3-phase complementary switching, 2 channels for 5-phase complementary switching, 10 channels for single-phase complementary switching

- 4-channel high-resolution PWM with timing adjustment down to 195ps (picoseconds)

- 12-bit A/D converter x 3 units, 12-bit D/A converter x 2 channels

- 6 channels of comparator

- 6 channels of pseudo-differential PGA

- Trusted Secure IP Lite enables high level of Root of Trust

- AES and other encryption engines, key management, flash memory protection

Description

The RX66T group of microcontrollers is designed for motor control applications. The max. 160MHz RXv3 CPU core enables up to four inverters to be controlled simultaneously, with advanced security and safety functions for inverter control applications.

Parameters

| Attributes | Value |

|---|---|

| Main CPU | RXv3 |

| Program Memory (KB) | 256, 512, 1024 |

| RAM (KB) | 64, 128 |

| Carrier Type | Full Carton (Tray), Tray |

| Supply Voltage (V) | 2.7 - 5.5 |

| I/O Ports | 33, 48, 61, 78, 80, 81, 93, 119 |

| DRAM I/F | No |

| Temp. Range (°C) | Ta = -40 to +85, Ta = -40 to +105 |

| Operating Freq (Max) (MHz) | 160 |

| Ethernet speed | No |

| Ethernet (ch) | 0 |

| EtherCat (ch) (#) | 0 |

| USB FS (host ch/device ch) | ( 0 / 0 ), ( 1 / 1 ) |

| USB HS (host ch/device ch) | ( 0 / 0 ) |

| USB SS (host ch/device ch) | ( 0 / 0 ) |

| SCI or UART (ch) | 6, 7 |

| SPI (ch) | 7, 8 |

| I2C (#) | 7, 8 |

| CAN (ch) | 1 |

| CAN-FD (ch) | 0 |

| Wireless | No |

| SDHI (ch) | 0 |

| High Resolution Output Timer | Yes |

| PWM Output (pin#) | 31, 38, 40, 48 |

| 32-Bit Timer (ch) | 10 |

| 16-Bit Timer (ch) (#) | 13 |

| 8-Bit Timer (ch) | 8 |

| Standby operable timer | No |

| 12-Bit A/D Converter (ch) | 8, 15, 19, 22, 30 |

| 24-Bit Sigma-Delta A/D Converter (ch) | 0 |

| 16-Bit D/A Converter (ch) | 0 |

| 12-Bit D/A Converter (ch) | 2 |

| 8-Bit D/A Converter (ch) | 0 |

| Capacitive Touch Sensing Unit (ch) | 0 |

| Segment LCD Controller | No |

| Security & Encryption | Unique ID, Unique ID, AES, MAC, TRNG |

Application Block Diagrams

|

Smart HVAC Control with Integrated Slave Actuator

This slave actuator design for HVAC systems offers low power, secure bi-directional packet data flow, and automatic routing.

|

|

3KW Off-Board Electric Vehicle Charger

3KW AC/DC converter can charge light electric vehicles or power high wattage loads.

|

|

|

Smart Solar Tracking and Cleaning System

Solar panel tracker boosts efficiency with optimized exposure, automated cleaning, and cloud connectivity.

|

|

Digital Power Conversion with Totem Pole Interleaved PFC

High-efficiency power supply platform featuring totem pole PFC and LLC resonant DC/DC converters.

|

|

Industrial Ethernet Gateway and Sensor System

Quick-start modules enable seamless Ethernet connectivity for sensors and gateways.

|

|

Functional Safety Network with Safety Drive System

Enhance industrial safety with a motor drive and network system powered by two 32-bit RX72N MCUs, ensuring reliable control and emergency power cutoff.

|

Additional Applications

- Industrial

- Office automation

- Home appliances

Applied Filters:

Filters

Software & Tools

Sample Code

Simulation Models

This video introduce the product features of RX-T series for inverter control.

https://www.renesas.com/rx-motor-control

This demonstration shows motor control and fault detection with a Renesas MCU. The e-AI unit detects an abnormality with the motor installation from the acceleration sensor. In addition to the acceleration sensor, malfunction detection is also possible by using information stored in the motor control MCU, such as current, torque and rotation speed. e-AI makes motor control more intelligent, predicts the maintenance schedule, identifies the location of the failure, and realizes the endpoint in real time.

Motor control equipped with eAI to enable failure prediction.