Features

- Voltage supply: 3.3V±0.3V or 5.0V±0.5V

- Qualified for industrial applications operating from -40°C to +125°C

- Output interfaces: high-speed UART, ABI, step/dir, and I2C

- Rotational speed: up to 600K rpm, with less than 100ns propagation delay

- High-accuracy sensor with up to 19-bit resolution and 15-bit accuracy (integrated vernier)

- True power-on position information with ABI and step/dir

- On-axis and off-axis implementations support

- Automatic gain control (AGC) to compensate for air-gap variations

- Autocalibration and 16-point linearization for enhanced accuracy

- On-chip failure diagnostics

- External auxiliary sensor input

- Fully customizable sensing element design using the Renesas Inductive Position Sensor Coil Optimizer tool

Description

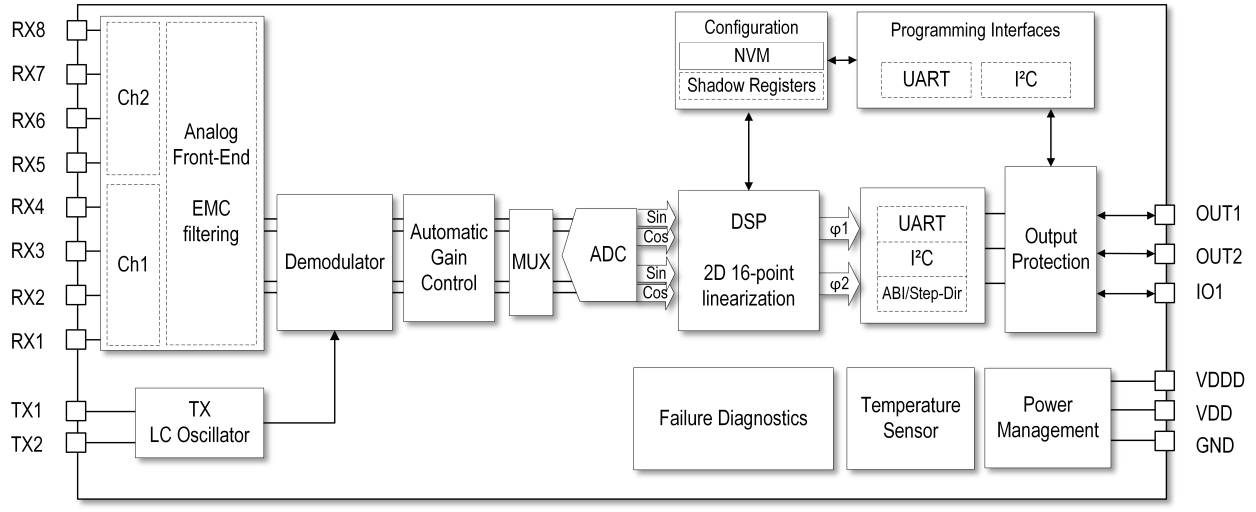

The RAA2P3226 is a magnet-free, inductive position sensor IC designed for absolute rotary, linear, or arc position sensing in industrial applications. It operates on the principle of eddy currents, detecting the position of a simple metallic target that is moving above a set of coils, comprising one transmitter coil and two sets of receiver coils. Equipped with dual receiver sets, the RAA2P3226 is ideally suited for high-performance sensor solutions, delivering up to 19-bit resolution and 15-bit accuracy.

Inductive sensing technology offers significant advantages over magnetic technology, including greater flexibility, easier system integration, and enhanced performance, reliability, and cost efficiency. As a result, it is becoming the preferred choice for a wide range of industrial applications.

Parameters

| Attributes | Value |

|---|---|

| Function | Position Sensor |

| Resolution (bits) | 19 |

| Supply Voltage (V) | 3.3 - 5 |

| Interface | I2C, ABI, Step/Dir, UART |

| Temp. Range (°C) | -40 to 125°C |

Package Options

| Pkg. Type | Pkg. Dimensions (mm) | Lead Count (#) | Pitch (mm) |

|---|---|---|---|

| TSSOP | 5.0 x 4.4 x 1.0 | 16 | 0.65 |

Application Block Diagrams

| Turntable System This turntable system features a low-power MCU and RIAA preamp for precise motor and audio control. |

| Mini BLDC Servo BLDC servo drives up to 75W motors with precise, efficient integrated control. |

Additional Applications

- Optical encoder replacement

- Magnetic encoder replacement

- Linear motor

- Robotics

- Medical applications

- Industrial automation

Applied Filters:

Filters

Software & Tools

Sample Code

Simulation Models

RAA2Px inductive position sensors boast high accuracy and high resolution with analog and digital interfaces. The devices offer a high-performance solution for optical and magnetic encoder replacement, effectively lowering overall bill-of-materials costs.

Visit the RAA2P3226, RAA2P3200, and RAA2P4200 position sensor pages to learn more about each device.

Related Resources