Improvements to the UX (user experience) and UI (user interface) enhancing the added value of our products are becoming increasingly important, and Renesas has a lineup of RX family microcontrollers equipped with capacitive touch sensors to make it possible. The RX140 32-bit microcontroller with a new-generation capacitive touch sensor is now available.

Renesas has more than 10 years of market experience in the touch microcontroller business, and the RX family has also been adopted into many products equipped with second-generation touch key IP in the control panels of home appliances, with more than 40 million units shipped in 2020. The latest new-generation touch-IP has dramatically improved noise immunity and water resistance, making it possible to utilize it in a wide range of applications, including water-related applications.

Improved Water Resistance through Shield Electrode Driving

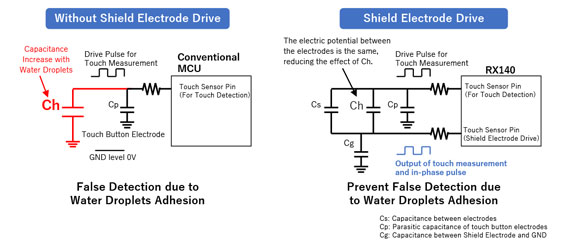

With the conventional method, the capacitance increases when there are water droplets on the touch button electrode, and it can be mistakenly confirmed that this change was caused by a touch. The new touch-key IP on the RX140 uses a direct drive system to shield the electrode using a terminal for the touch sensor. This method outputs the drive pulses for touch measurement from both touch detection and the shield electrodes, allowing the shield electrode and the touch button electrode to be on the same potential, reducing the effect of the increased capacitance that can be caused by the presence of water droplets. As a result, it is possible to keep the false detection low.

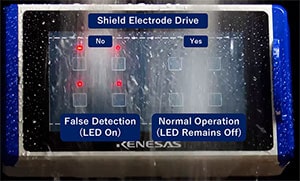

Figure 1 shows how the new method has improved water resistance. If the shield electrode is not driven (left), a false detection occurs due to the water adhering, and the LED is lit, but if the shield electrode is driven (right), the false detection does not occur, even if water adheres to it. As such, the new system has high water resistance, so it can be introduced with confidence for the operation of water-related applications such as water taps and showerheads, and can improve the design and operability unique to touch keys.

Industry-leading Noise Immunity

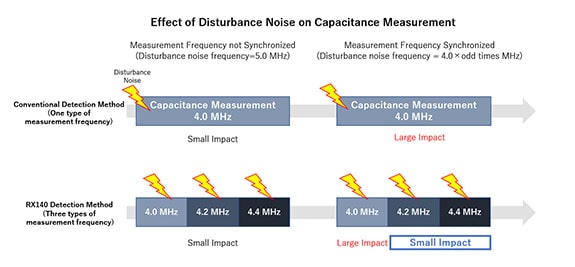

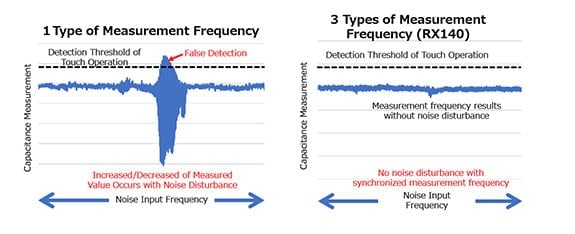

The new touch IP uses a new detection method to reduce the effect of disturbance noise. Since conventional detection methods use just one measurement frequency to measure the capacitance, the measurement results are greatly affected when the frequency of external disturbance noise is synchronized with the measurement frequency. In contrast, the new method that comes with the RX140 can use three different measurement frequencies to correctly measure one of the remaining measurement frequencies, even if it is affected by external disturbance noise.

Figure 5 shows the measurement results of the radiated electromagnetic field immunity test. The new method does not cause any increase or decrease in the measurement values due to the effects of noise when compared to the case with just one type of measurement frequency, and it can be seen that there are no false detections.

Based on the results from our evaluation board, it is now possible as a result of the increased noise immunity, through the adoption of the new method, to clear the standard for noise immunity assessment, IEC/EN 61000-4-6 Level 3 (conducted immunity), as well as to achieve Level 4 for IEC/EN 61000-4-3 (radiated immunity).

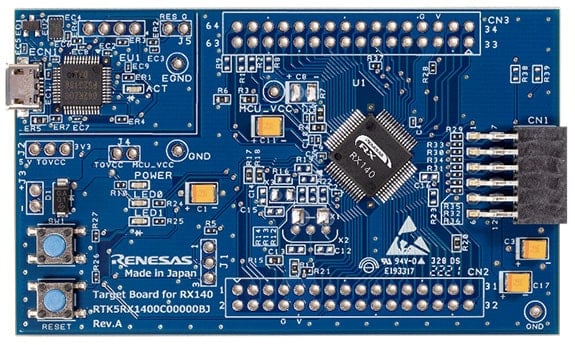

The RX family includes a target board for initial evaluation. This is an inexpensive evaluation board and all signal pins are accessible for early deployment consideration. In addition, this board is equipped with an emulator circuit. Touch operation was not available with the previous target board, but initial touch evaluation is possible with the RX140 Target Board that comes with the capacitive touch design pattern. It is highly recommended to use the RX140 target board to verify touch operation.

Visit the RX140 product page and the Target Board for RX140 page for more information.