Features

- CPU Core:

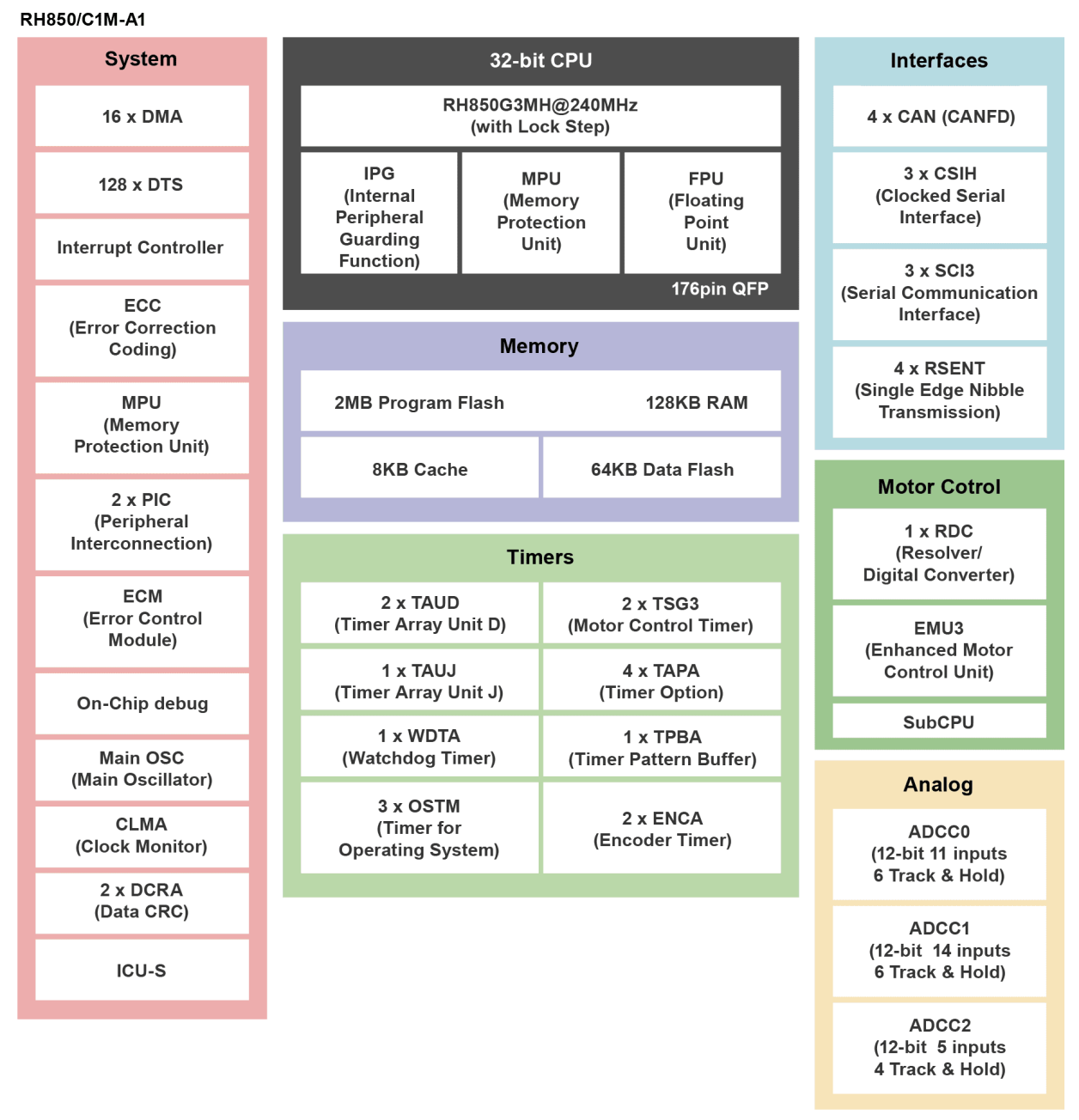

- C1M-A1: 240MHz core (Inc. Lockstep dual core x1)

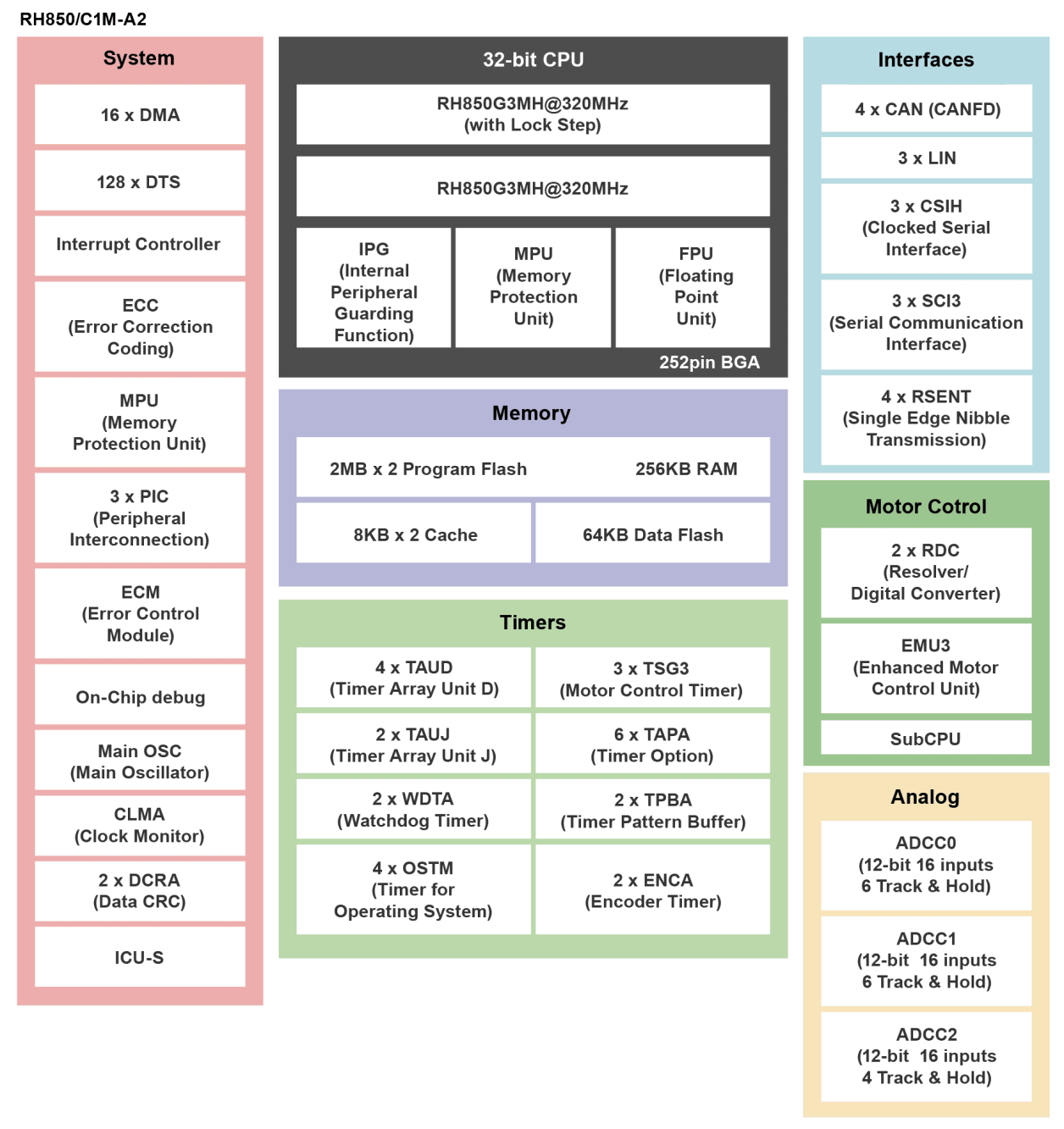

- C1M-A2: 320MHz core x2 (Inc. Lockstep dual core x1)

- FPU

- Clock:

- Main Oscillator: 20 MHz

- PLL with selectable SSCG mode: 240 or 320 MHz

- PLL without SSCG mode: 80 MHz

- On-chip low-speed oscillator: 240 kHz

- Data transfer: DMAC / DTS

- Timer:

- Timer array unit D (TAUD) 2 or 4 units

- Timer array unit J (TAUJ) 1 or 2 units

- Motor control timer (TSG3) 2 or 3 units

- Encoder timer (ENCA) 2 units

- Analog: SAR A/D Converter 30 or 48ch, 3 units

- Communication Interfaces:

- Clocked Serial Interface H (CSIH) 3 channels

- CAN interface(RS-CANFD) 4 channels

- LIN interface(RLIN3) 3 channels

- Serial Communication Interface (SCI3) 3 channels

- RSENT 4 channel

- Motor Control:

- Motor control timer (TSG3) 2 or 3 units

- R/D converter (RDC3A) 1 or 2 units

- Enhanced motor control unit (EMU3) 1 unit

- Safety:

- Multi-Input Signature Generator (MISG)

- Clock Monitor

- Watchdog Timer

- Secure Watchdog Timer

- Memory protection function

- Power Supply Voltage:

- 1.15 - 1.35 V (CPU core)

- 4.5 - 5.5 V (I/O, System, AD converter, RD converter)

- Temperature: Tj= -40 - +150°

Description

The RH850/C1M-Ax ASIL-C microcontroller is equipped with an RH850 Family G3MH CPU core, which operates at a frequency of 1x 240MHz for C1M-A1 and 2x 320MHz for C1M-A2, providing high processing power. Along with the ROM, RAM and DMA, it includes various timers such as a motor control timer, various serial interfaces including CAN (CAN FD compatible), a 12-bit A/D converter (ADC), an R/D converter (RDC3A) that converts position-sensor output signals into digital angle data and a parallel embedded motor control unit (EMU3), providing a peripheral function set that is ideal for motor control in HEV/EV traction-inverter applications. In addition, C1M-A2 can simultaneously control two motors, e.g. for a starter/generator system.

Parameters

| Attributes | Value |

|---|---|

| Main CPU | G3MH |

| Program Memory (KB) | 2048, 4096 |

| RAM (KB) | 128, 256 |

| Supply Voltage (V) | 4.5 - 5.5 |

| I/O Ports | 81, 99 |

| DRAM I/F | No |

| 3D GPU | No |

| Temp. Range (°C) | -40 to +150 |

| Ethernet speed | No |

| Ethernet (ch) | 0 |

| EtherCat (ch) (#) | 0 |

| USB FS (host ch/device ch) | ( 0 / 0 ) |

| USB HS (host ch/device ch) | ( 0 / 0 ) |

| USB SS (host ch/device ch) | ( 0 / 0 ) |

| PCI Express (generation and ch) | No |

| SCI or UART (ch) | 4 |

| SPI (ch) | 3 |

| CAN (ch) | 0 |

| CAN-FD (ch) | 4 |

| Wireless | No |

| SDHI (ch) | 0 |

| PWM Output (pin#) | 0 |

| 32-Bit Timer (ch) | 4, 8 |

| 16-Bit Timer (ch) (#) | 32, 64 |

| 8-Bit Timer (ch) | 0 |

| Standby operable timer | No |

| Asynchronous General Purpose Timer / Interval Timer (ch) | 0 |

| 16-Bit A/D Converter (ch) | 0 |

| 14-Bit A/D Converter (ch) | 0 |

| 12-Bit A/D Converter (ch) | 30, 48 |

| 10-Bit A/D Converter (ch) | 0 |

| 24-Bit Sigma-Delta A/D Converter (ch) | 0 |

| 16-Bit D/A Converter (ch) | 0 |

| 12-Bit D/A Converter (ch) | 0 |

| 10-Bit D/A Converter (ch) (#) | 0 |

| 8-Bit D/A Converter (ch) | 0 |

| Capacitive Touch Sensing Unit (ch) | 0 |

| Graphics LCD Controller | No |

| MIPI Interfaces (CSI) (ch) | 0 |

| Image Codec | No |

| Segment LCD Controller | No |

| Security & Encryption | Yes |

Application Block Diagrams

| xEV Inverter with Inductive Position Sensor (IPS) This cost-efficient xEV inverter system with IPS offers high accuracy, noise immunity, and reduced BOM. |

| Motor Generator System High-performance xEV motor control design with ASIL C support, lock-step CPUs, and reduced BOM cost. |

| Automotive Monitoring Function Extension Compact CMIC-based system for integrating motor monitoring and protection functions in automotive systems. |

| Low Voltage Inverter for 2/3 Wheeler Traction Motor Control Inverter for 2/3 wheelers using automotive MCUs and analog products, designed for motor control. |

| xEV Inverter Compact, efficient xEV inverter design with advanced calibration tools and proven 100kW motor performance. |

Applied Filters: