Many of us love lush green lawns but it requires regular maintenance costing us time and money. A robotic lawn mower has come to our rescue to keep the lawn greener, healthier, and always looking freshly cut and immaculate all of the time, saving us time for ourselves as well as the expense of landscapers. We just set it up once and don’t worry about taking care of the lawn anymore. The lawn mower will autonomously leave its docking station at the scheduled time and diligently cut the lawn every day. The benefits don’t stop there. Compared to conventional lawn mowers, robotic lawn mowers are much quieter and safer to operate, require very low maintenance, are better for our environment, and provide the convenience of remote programming, controlling and monitoring the lawn mower. When it mulches the grass, it returns the finely cut grass clippings along with its nutrients back to the soil. This leads to a reduced need for fertilization and the need to collect the cut grass for disposal is eliminated. In contrast, the cuttings of a conventional lawn mower, when operated once a week, clumps on the grass, making it look unsightly.

Robotic lawn mowers can avoid obstacles like flower beds, ponds, etc. without user intervention due to electronic boundaries created by a perimeter wire or with the use of collision avoidance sensors. Robotic lawn mowers have much smaller and lower powered blades. The blades are safely tucked under the machine, away from its edges and the user doesn’t need to go near them while it is in operation, making it a safer alternative to conventional mowers. Many robotic lawn mowers also have lift and tilt sensors which initiate an immediate emergency blade stop when a possible injury situation is detected. The robotic lawn mower market is poised to grow by 436.16 million USD during 2020-2024 progressing at a CAGR of over 19% during the forecast period [1].

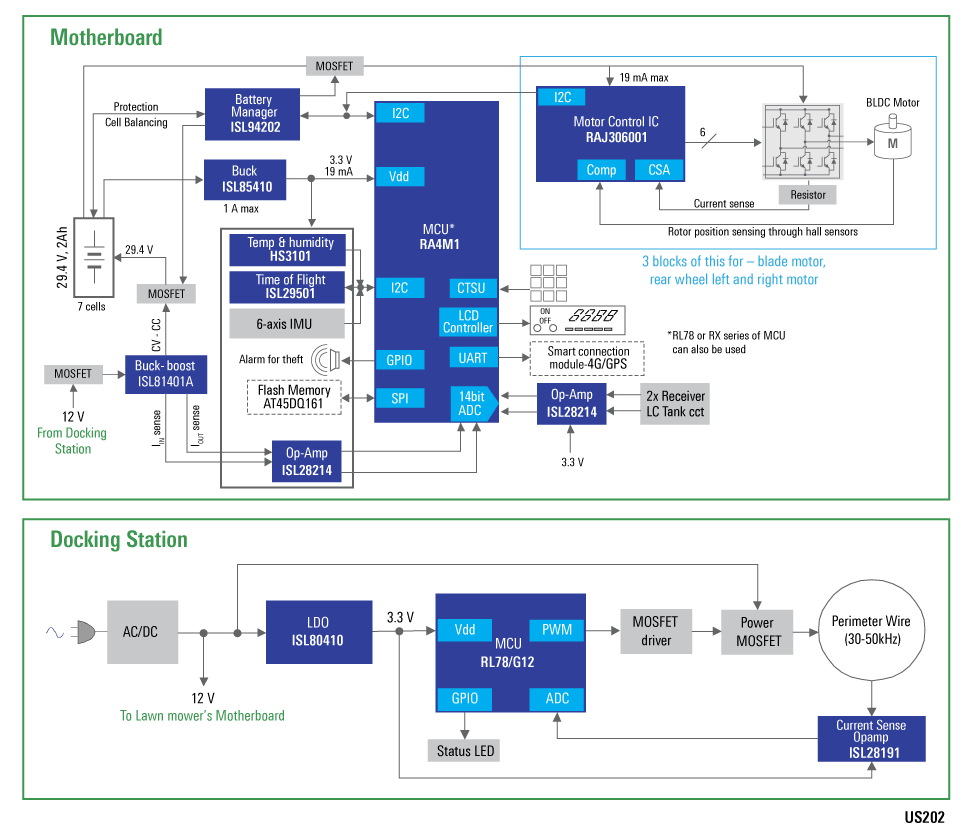

Renesas has come up with a winning combo solution for a robotic lawn mower, providing all the key components (see Figure 1). It consists of a motherboard for the robot and a separate board for the docking station. The motherboard is based on the highly integrated RA4M1 48MHz Arm® Cortex®-M4 MCU with a built-in LCD controller, capacitive touch sensing unit (CTSU), multiplexed 14-bit ADC, and FreeRTOS support for a simplified system design process and superior user experience. The RAJ306001, a general-purpose motor control IC for 3-phase brushless DC motor applications with integrated analog front-end (AFE) and built-in firmware, ensures reduced BOM and fast time-to-market. It combines an MCU (RL78/G1F) and a pre-driver including half bridge gate drivers, 5V regulator, a current sense amplifier, hall IC comparators, Back-EMF amplifier, and various protection functions, all in a single package. The system has extremely low power consumption for longer battery life. The ISL94202 provides a feature-rich battery management system (BMS) for an up to 8 cells Li-ion battery with reliable safety features for cell balancing and protection while charging/discharging. The ISL81401A is a 4-switch wide input/output synchronous buck-boost controller that provides efficient battery charging in CV/CC profile. It supports on-the-fly bidirectional operation with independent control of voltage and current on both ends. The system implements rain detection using the HS3101 weatherproof humidity sensor and CTSU of the MCU for returning to docking station for safe operation. Collision detection is implemented using ISL29501 time-of-flight (ToF) sensors and lift/tilt detection is implemented using 6-axis IMU for stopping the blades, ensuring enhanced safety. It also provides an optional remote control and theft protection alarm choice using LTE/GPS connectivity.

The docking station is based on an ultra-low power general purpose RL78/G12 MCU with AC input feeding it and provides the 12V DC rail for charging the robot when docked. A perimeter wire is connected to the docking station and laid across the lawn which serves as an electronic fence for the robot. The perimeter wire carries a PWM pulsating signal which is sensed by the LC tank circuits on the motherboard.

For more information on this or other Winning Combinations please visit us at www.renesas.com/win and see how we are helping our customers accelerate their designs and go to market faster!