Sensors & Actuators

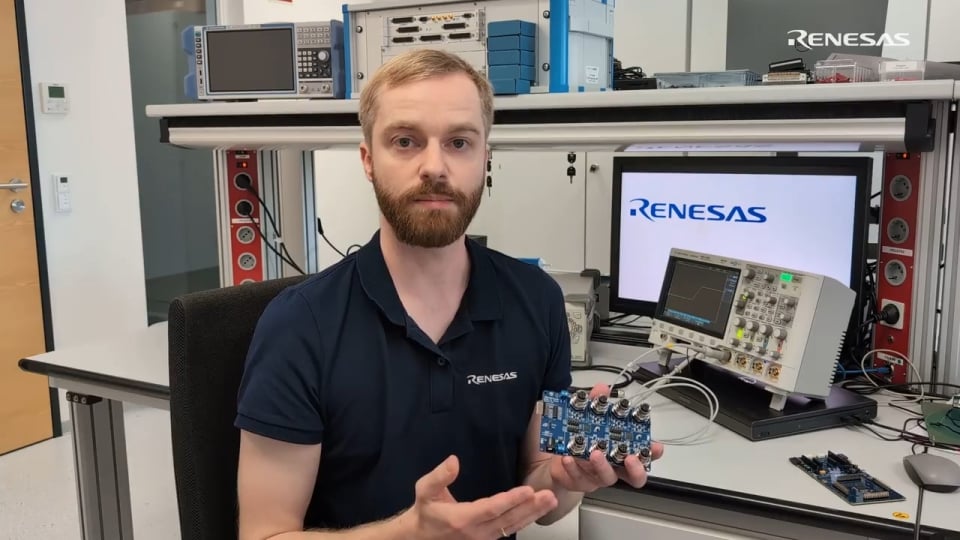

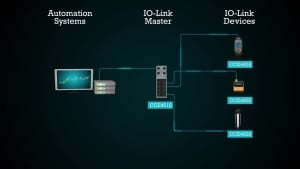

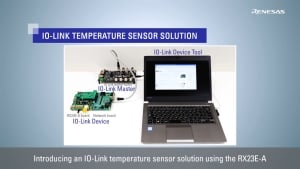

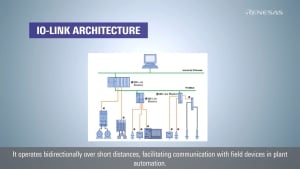

Embedded sensors and actuators are vital to industrial automation, but managing them can be challenging. IO-Link simplifies this with an intelligent point-to-point connection, enabling fast, direct access to machine data. It streamlines assembly, operation, and maintenance while reducing parts, improving diagnostics, and enhancing transparency down to the sensor level. The result? Faster commissioning, lower costs, and increased uptime for efficient, reliable production lines.