Over the last decade, the number of connected Internet of Things (IoT) devices has grown exponentially across markets ranging from medical devices and smart homes to industrial automation. These smart, connected endpoints implement complex and compute-intensive applications; run real-time control loops; analyze large amounts of data; integrate sophisticated graphics and user interfaces; and run advanced protocols to communicate with the cloud. Machine learning has enabled voice and vision AI capabilities at the edge, empowering devices to make intelligent decisions and trigger actions without cloud intervention. This reduces latency and power consumption, saves bandwidth, and increases privacy. Advanced security has also become an integral part of these systems, as users demand advanced cryptographic accelerators on-chip, robust system isolation, and security for data at rest as well as in motion. Applications also require lower power and fast wake-up times to prolong battery life and reduce overall system power consumption.

These new and emerging requirements drive the need for greater processing power in embedded systems. Fast, reliable, and low-power non-volatile storage of code and data is also needed for the implementation of these sophisticated applications. Traditional systems used either powerful MPUs or multiple MCUs to perform these functions. Recently, we are seeing the emergence of high-performance multi-core MCUs with performance approaching that of MPUs – some with hardware AI accelerators – that can handle all these functions with a single chip. These high-performance MCUs provide a powerful alternative to MPUs for applications where power consumption and cost are critical concerns. MCUs have several advantages over MPUs that make them particularly well-suited for these power-sensitive IoT applications – better real-time performance, integration of power management and non-volatile memory, single voltage rail, lower power, typically lower cost, and ease of use.

The need for higher performance and functionality while keeping power and costs low has driven the movement towards the use of finer process technology nodes like 28nm or 22nm. This movement has driven innovations in embedded memory technology, since embedded flash does not scale well below 40nm. Alternative memory technologies like Magnetoresistive Random Access Memory (MRAM) are being used to replace embedded flash for non-volatile storage. A number of silicon manufacturers like TSMC now provide embedded MRAM that can be integrated into an MCU.

Renesas' High-Performance MCUs Meet the Market Needs

Renesas designed the RA8M2 and RA8D2 single and dual-core MCUs to deliver the performance needed for high-performance applications. Featuring the Arm® Cortex®-M85 and Cortex-M33 cores, and delivering breakthrough performance of over 7300 CoreMark, these ultra-high performance MCUs can drive complex and compute-intensive applications. These MCUs are built on the 22nmULL process, enabling a magnitude increase in performance up to 1GHz on the Cortex-M85 core and lower power consumption. This performance, together with large on-chip memory, high-speed connectivity peripherals, external memory interfaces, and an optimized feature set, makes these MCUs ideal for a broad base of compute-intensive IoT and graphics applications.

The RA8M2 and RA8D2 devices include new embedded MRAM as non-volatile memory, delivering high endurance and data retention, faster writes with no erase needed, and lower leakage and manufacturing costs. To truly secure IoT applications, these two high-performance MCUs offer advanced security, immutable memory, and TrustZone®.

Performance and System Design Flexibility with Dual-Core MCUs

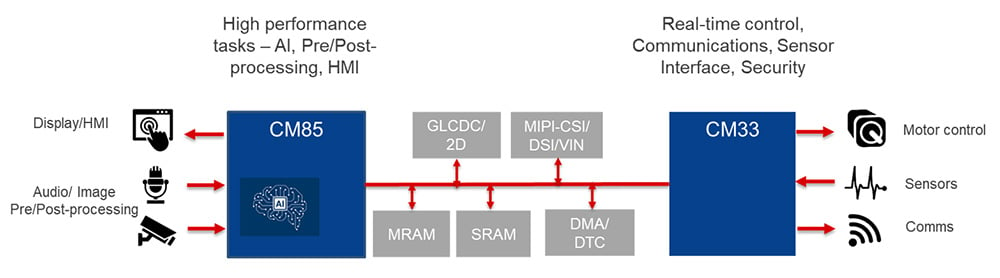

The single-core RA8M2 and RA8D2 MCUs feature the Cortex-M85 core running up to 1GHz, with Helium vector extensions to enable compute-intensive applications. On the dual-core option, a second Cortex-M33 core is added to allow efficient system partitioning, lower power wake-up, and operation. Either core can be configured to be a master or slave CPU and can be independently powered. Inter-processor communication is through flags, interrupts, and message FIFOs.

Dual-core MCUs significantly enhance the performance of IoT applications by enabling greater processing power, efficient task partitioning between the two cores, and improved real-time performance. System tasks can be assigned to different cores, leading to concurrent and more efficient system operation. One core can handle real-time control tasks, sensor interfaces, and communications, while the other, typically a higher-performance core, can handle the compute-intensive tasks, such as execution of neural network model operators, pre-processing of audio or image data, graphics, or motor control. This partitioning between the two cores can enable faster execution and overall improvement in system performance.

With optimal system task partitioning, dual cores can enable lower power consumption. Each core can be independently controlled, allowing them to run at frequencies optimal for the assigned tasks. The lower-performance Cortex-M33 core can be the housekeeping CPU, which enables low-power wake-up and operation. The higher-performance core can stay in low-power mode most of the time to be woken up only when high-performance processing is required. This segregation of tasks with the appropriate use of MCU resources results in overall lower system power consumption.

Dual cores also enable more robust system design. The high compute tasks can be separated from the more time-critical and safety critical tasks and real-time control loops, thus allowing a more robust system design. Any interruption on one core will not have an impact on the tasks of the second core. Dual cores can also enable functional safety with core isolation, redundancy, and optimal resource usage by safety critical and non-critical tasks.

Performance and Power Efficiency with Embedded MRAM

The move to lower process geometries has opened the doors to newer memory alternatives to flash, such as MRAM, that is making its entry into the embedded space as embedded MRAM (eMRAM) and is now included on the RA8M2 and D2 MCUs.

As MCU manufacturers scale to higher performance and functionality with finer process geometries, eMRAM is increasingly being used to replace embedded flash as the non-volatile memory of choice. One key factor that is making MRAM a viable option for use on MCUs is its ability to retain data through solder reflow, which allows the devices to be pre-programmed prior to being soldered on the board. One additional advantage is that MRAM can be used to replace not just the embedded flash (for code) but also SRAM (for data storage) due to the byte addressability (except in cases with security concerns with retention of data across power cycles). Embedded MRAM is now supported by major silicon foundries, which allow MCU manufacturers to incorporate MRAM into new chip designs with minimal cost overhead.

Special care needs to be taken to prevent MRAM from being corrupted by external magnetic fields present in close proximity to the device. MCU manufacturers typically specify magnetic immunity in idle, power off, and operational modes. In order to avoid corruption of MRAM bits, designers will need to provide adequate spacing between an external magnetic field source and the MRAM-based device, so as not to exceed this magnetic immunity specification. Shielding the MRAM with specialized materials is another option to protect the MRAM from a strong magnetic field.

Key Advantages of MRAM Technology:

- True random access non-volatile memory with higher endurance and retention as compared to flash

- Faster write speeds as compared to flash, with no erase needed

- Byte-addressable and simpler to access than flash, similar to SRAM, improving both performance and power

- No leakage when in standby, making them much lower power than SRAM

- Reads are non-destructive and do not need to be refreshed, so it is an alternative to DRAM

- Magnetic layers are not susceptible to radiation, similar to flash

- Fewer mask layers are needed for MRAM as compared to flash, thus lowering costs

- Scales well for lower process technology nodes and, as such, provides a viable alternative to embedded flash

MRAM Applications

MRAM's low power and non-volatile characteristics make it ideal for various IoT applications as a unified memory, replacing embedded flash, SRAM, or battery-backed SRAM. It can also be used to replace DRAM for data logging applications that require high density, low power, and non-volatile data storage. The immunity to radiation makes it ideal for medical applications in clinical settings and space applications. MRAM can also be used in industrial control and robotics, data center, and smart grid applications, for real-time data storage, fast data retrieval, and replacing battery backup SRAM.

Not forgetting the Edge AI market using machine learning – here, the MRAM can be used to store the AI neural network models and weights, which are retained across power cycles and do not need to be reloaded for execution each time. MRAM, with its fast read/writes, low power, and high endurance, is particularly suited for these applications requiring high processing performance.

In summary, the new and emerging use cases drive the need for high-performance and specialized feature sets on MCUs. Powerful CPU cores, multi-core architecture, new memory technologies like MRAM, and rich peripherals are integrated on RA8M2 and RA8D2 MCUs to support the needs of these cutting-edge applications.

For more information, visit renesas.com/ra8d2 and renesas.com/ra8m2.