Overview

Description

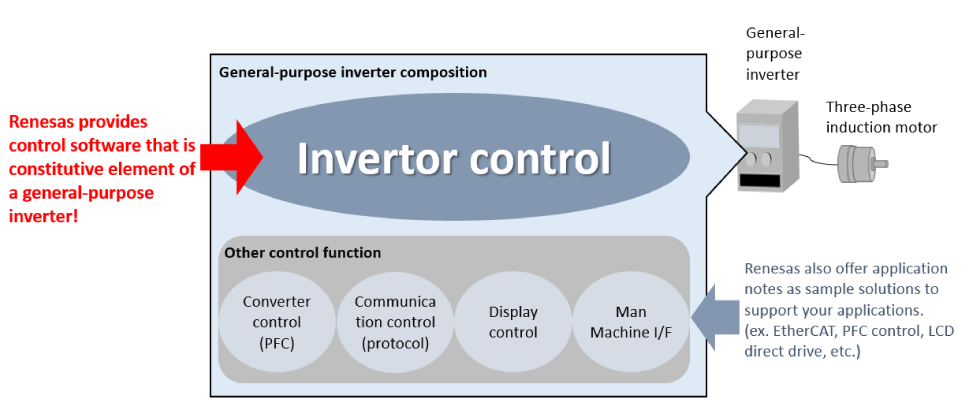

The three-phase induction motor solution focuses on the control of a three-phase induction motor, widely used in industrial pump, fan, and compressor applications. By providing inverter control sample software, Renesas aims to give the customer a head-start on inverter control development shortening the development time. Using this solution can simplify the development of inverter applications.

● Solution concept

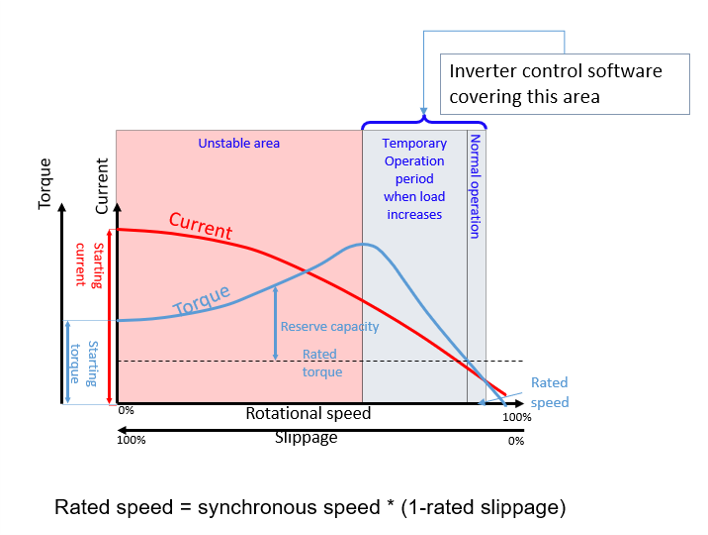

This solution controls an induction motor at rated speed under normal conditions, while it's controlled by high torque ratio to avoid slippage in temporary high load condition. Also, this solution can be flexible in the frequent change of rotation speed. Customers easily develop inverter control software for target applications by using this solution.

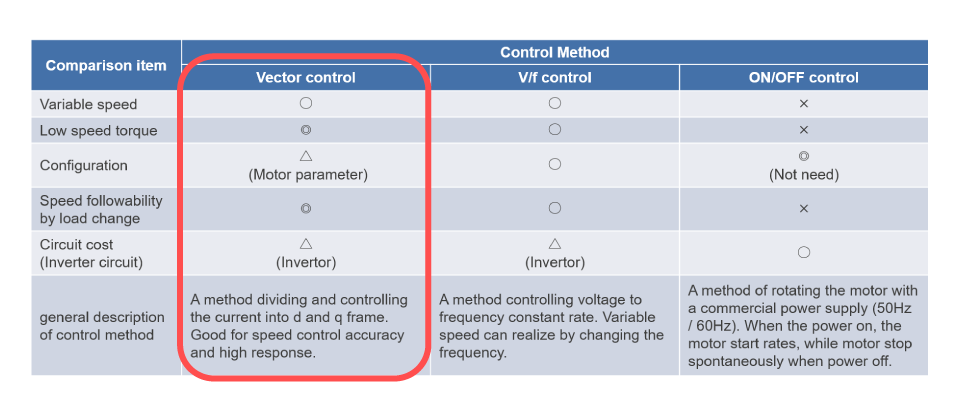

Three-phase induction motor solution use vector control that expects high control accuracy and high response

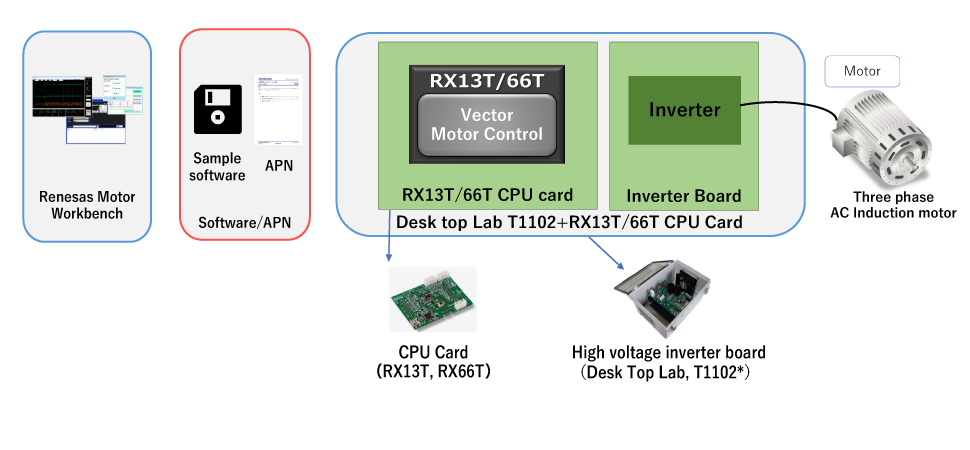

● System configuration & Solution menu list

● Solution Example

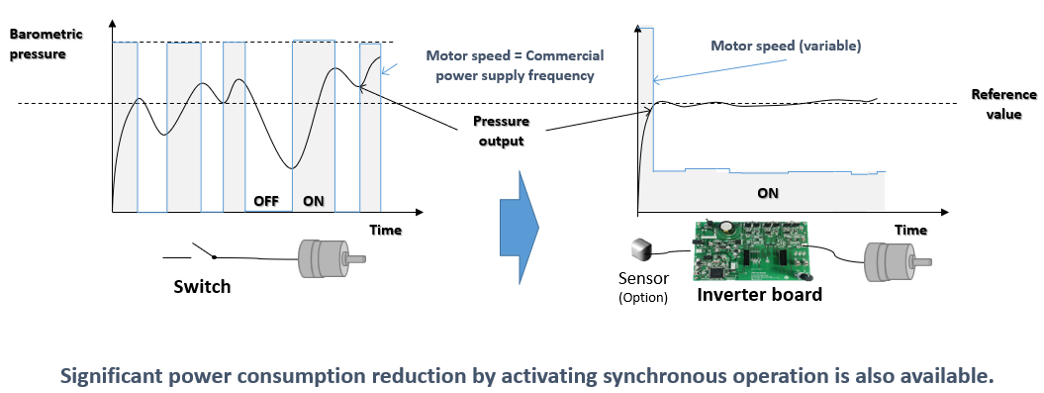

Issue: Unstable pressure output, due to inflexibility caused by ON/OFF control.

Solution: Variable control is achieved by inverter control. Stable control is also available by adding a detecting sensor in the inverter board.

Features

- Vector control sample software for a three-phase induction motor ready for customer evaluation

- Significant time and cost savings for induction motor development

- With speed sensorless vector control function, enable to reduce expensive speed sensors/BOM costs, and improve system reliability.

Comparison

Applications

Software

Software Downloads

| Type | Title | Date |

|---|---|---|

| Sample Code | ZIP 2.59 MB 日本語 Compiler: CC-RX Function: Application Example IDE: CS+ | |

| Sample Code | ZIP 2.53 MB 日本語 Compiler: CC-RX Function: Application Example IDE: CS+ | |

| Sample Code | ZIP 2.08 MB 日本語 Compiler: CC-RX Function: Application Example IDE: CS+ | |

| Sample Code | ZIP 2.16 MB 日本語 Compiler: CC-RX Function: Application Example IDE: CS+ | |

4 items | ||

Resources

Support

Support Communities