Due to the diversity of lifestyles, current products are expected to have high accessibility and advanced system control for various users and environments. This results in the need for a high-performance CPU and a sensor system capable of detecting various materials.

There are many applications that use inexpensive sensors (photosensors), as well as expensive sensors (piezoelectric sensors and ultrasonic sensors) to detect material. Photosensors are easy to use and can be installed in various places in the equipment. However, accumulation and adhesion of dust can cause erroneous detection and deterioration. In addition, it can complicate the assembly due to the routing of data lines and power lines.

The capacitive sensor embedded in the RL78/G22 can perform detection without direct contact, making it possible to create a system that is less susceptible to dust, etc., and solve problems with sensors depending on the usage environment. Furthermore, with the sensor built into the MCU, a system can be constructed using only electrodes.

A capacitive sensor measures the amount of charge generated between an electrode and material. Since the amount of electric charge changes in ratio to the dielectric constant of material, it is generally affected by material with a higher dielectric constant than the dielectric constant of air. Therefore, it can detect various objects such as human body, water, oil, glass, plastic, paper, and metal.

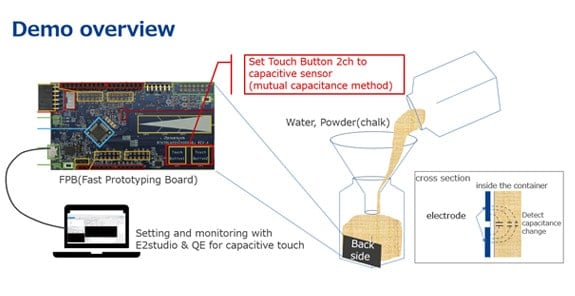

The RL78/G22 Fast Prototyping Board (FPB) makes evaluating microcontrollers and has touch button/touch slider electrodes that can be used to easily evaluate capacitive sensors too.

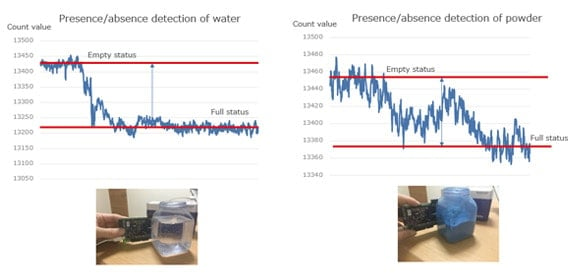

The following demonstration shows how to use the touch button electrode in the FPB to detect material (water, powder – chalk).

The state change inside the container is measured with a capacitive sensor (mutual capacitance method).

Demo procedure

- Connect PC and FPB

- Electrode settings with e² studio and QE for capacitive touch

- Bring the FPB electrode into contact with the container, and pour water or chalk into the container.

- Monitor with QE for capacitive touch

The demo shows that the FPB makes it easy to evaluate capacitive sensors. The RL78/G22 provides added value to the customer's product in aspects of system cost and functionality by the capacitive sensor. Download the free software required for development using the following links.

RL78/G22 development environment

- RL78 Family Using QE and SIS to Develop Capacitive Touch Applications (R01AN5512EJ0210)

- QE for Capacitive Touch: Development Assistance Tool for Capacitive Touch Sensors

- e² studio -information for RL78 Family

Visit www.renesas.com/rl78g22 for more details on the microcontroller.