Features

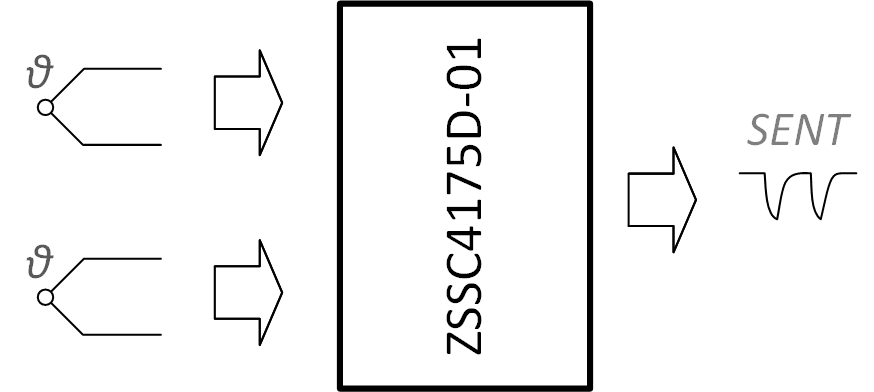

- Two differential thermocouple element inputs and an on-chip temperature sensor, available for cold-junction compensation and temperature output

- Operating temperature range: -40°C to 150°C

- Accuracy: Up to 5K at 1000°C hot junction

- Supports N-type thermocouples

- NVM memory for configuration, calibration data, and configurable measurement and conditioning functionality

- SENT output compliant to SAE J2716 JAN2010 (SENT Rev.3) and APR2016 (SENT Rev.4) standards

- Supports output of one or more thermocouple signals and product identification via a single SENT interface connection

- End-of-line calibration process minimizes production costs

- No external trimming or components required

- Qualified according to AEC-Q100 Grade 0

- Enhanced diagnostic features for sensor modules

Description

The ZSSC417xD provides precise amplification and correction of sensor signals, with possibilities for digital compensation of offset, drift, sensitivity, and nonlinearity. It features integrated non-volatile memory (NVM) for reliable automotive use and supports SENT for fast data transmission and One-Wire Interface (OWI) for easy calibration. Optimized for automotive environments, the ZSSC4175D offers robust protection, excellent EMC, and digital calibration, reducing costs and noise sensitivity while delivering superior performance. The ZSSC4175D-01 offers two independent measurements and linearization of N-type thermocouples. Cold-junction is compensated via internal chip temperature. Output data is transmitted via SENT interface.

Parameters

| Attributes | Value |

|---|---|

| Function | Voltage SSC |

| Automotive Qual. | Yes |

| Supply Voltage (V) | - |

| Input Type | Thermoelement SSC |

| Interface | SENT, I2C |

| Adj. Analog Gain | - |

| Resolution (bits) | 15 |

| Sample Rate Max (KHz) | 0.5 |

| Temp. Range (°C) | -40 to 150°C |

Application Block Diagrams

|

Automotive Sensor with CAN/LIN Interface

Automotive sensor system offers accuracy, flexibility, and reliable performance with SSC, MCU, LIN/CAN support.

|

Applied Filters:

Filters

Software & Tools

Sample Code

Simulation Models

Modern vehicles are filled with complex sensor systems to achieve optimal performance and lower emissions. IDT's (acquired by Renesas) ZSSC416x and ZSSC417x family of sensor signal conditioner ICs are ideal for use in the engine and exhaust system. Sensing differential pressure at the mass airflow intake using a single IC attached to two sensors lowers power consumption and improves accuracy compared to traditional sensing systems. Manifold pressure and temperature sensing also benefit from using a dual input IC, with higher accuracy measurements resulting in a more optimal fuel mix.

The IDT ZSSC416x and ZSSC417x family of sensor signal conditioners provide a platform for measurement systems with improved accuracy, reliability, and performance with lower power consumption. The family of devices provides highly accurate amplification with integrated compensation, correction, and calibration, while also sharing a common four-millimeter by four-millimeter QFN package and toolset to reduce development and assembly costs.

Related Resources

Transcript

Modern vehicles are filled with complex sensor systems to achieve optimal performance and lower emissions. IDT's ZSSC416x and ZSSC417x family of sensor signal conditioner ICs are ideal for use in the engine and exhaust system. Sensing differential pressure at the mass airflow intake using a single IC attached to two sensors lowers power consumption and improves accuracy compared to traditional sensing systems. Manifold pressure and temperature sensing also benefits from the use of a dual input IC, with higher accuracy measurements resulting in a more optimal fuel mix.

High temperature sensing across the turbo-charger benefits from a simpler design and lower cost with both thermocouples connecting to the same IC. At the diesel particulate filter, IDT products enable more accurate measurements of filter saturation, resulting in less fuel waste for filter purging. Selective catalytic reduction adds urea to the exhaust to reduce harmful emissions. Improved measurement accuracy leads to better control of urea dosing, reducing urea overuse and refilling costs for the vehicle owner. By more accurately measuring temperature and pressure in the fuel line, the control unit can provide the best fuel/air mix, lowering emissions and improving engine performance.

Compared to traditional anemometers, the sensors used with IDT sensor signal conditioner products are more durable in the harsh environment of exhaust mass airflow measurements, leading to a more reliable, lower power solution. The IDT ZSSC416x and ZSSC417x family of sensor signal conditioners provide a platform for measurement systems with improved accuracy, reliability, and performance with lower power consumption. The family of devices provides highly accurate amplification with integrated compensation, correction, and calibration, while also sharing a common four-millimeter by four-millimeter QFN package and tool set to reduce development and assembly costs. For more information on IDT's ZSSC416x and ZSSC417x sensor signal conditioners, visit idt.com

ZSSC416X and ZSSC417X provide highly accurate amplification and calibrated correction of sensory data for resistive bridge and voltage source sensors. The family features SENT 3.0-based ICs and is designed for use in automotive applications. With available diagnostic info, rugged circuit protection, and excellent electromagnetic compatibility.

The family aids designers by lowering power consumption, reducing component count, and saving time spent calibrating sensors. Additionally, the availability of dual-bridge inputs also reduces system complexity and footprint. All of these are important considerations in modern automotive applications where power and space come at a premium.

Related Resources

TRANSCRIPT

I'm Chris Anderson at the EEWeb Tech Lab, and today, we'll discuss ZMDIZSSC416X and ZSSC417X family of sensor signal conditioners. ZSSC416X and ZSSC417X provide highly accurate amplification and calibrated correction of sensory data for resistive bridge and voltage source sensors. The family features SENT 3.0-based ICs and is designed for use in automotive applications. With available diagnostic info, rugged circuit protection, and excellent electromagnetic compatibility.

The family aids designers by lowering power consumption, reducing component count, and saving time spent calibrating sensors. Additionally, the availability of dual-bridge inputs also reduces system complexity and footprint. All of these are important considerations in modern automotive applications where power and space come at a premium.

The ZSSC416X and ZSSC417X feature a widely programmable gain amplifier, a 12 to 18-bit EDC, an integrated temperature sensor, non-volatile memory to store calibration coefficients and configuration data, and a 16-bit risk MCU, that uses the calibration data and temperature measurement to compensate for offset, thermal drift, sensitivity variations, and non-linearity. End-of-the-line digital calibration over the I2C or one-wire interface improved calibration accuracy and reduces assembly cost and complexity.

So, on the evaluation kit for the ZSSC family, we have the communications board, which interfaces between the PC and the IC, we have the actual ZSSC board, which houses the IC, and that's sitting inside the socket. What I really like about this board, is ZMDI gives you access to all the pins, so you can plug in your own sensors, and you get access to the temperature sensor, as well as any other pins that you need to. So, you can really evaluate whether or not this is suitable for your application.

The third board acts as a pressure sensor. It's really just a potentiometer, though. On the software side, on the first time you'll come in and you'll load an XML file, and that will load in some basic parameters. And you can check those in the quick settings and then load those into RAM, write all to RAM. And then you'll want to come in here and calibrate your sensors. I've already done that for both the pressure and the temperature sensor. So, those are good to go. I've already written those out. And you can also see that I'm actually running software now, so if I adjust the potentiometer, or the pressure sensor, you can see in green, that's the calibrated measurement, and in blue, the raw measurement. So, you can see those adjusting up and down.

The pink graph is the internal temperature sensor. So, if I put a heat gun to that, you can see the temperature rise up. Now, I'm going to go ahead and stop. Now what we want to do is grab this hex version of the temperature data, and actually, we're going to run it again, so that we can get a fresh version, because it's been cooling off, of course. So, if we say, it's sitting at about 0X, 2E25. So, plug that into the calculator. Now, the I2C data, is 15-bit and the SENT data is 12-bits. We're going to divide this by eight, and then we're going to go compare this to what we see over the SENT interface. So, if we enter normal mode, this additional window will pop up, and we're going to try to freeze IDE23, as it comes down through the SENT data.

So, we can see 05BE. Which isn't far off from 5C4. So, that's just a different representation of the data, and you can see some other channels here for the SENT load data, as well.

Now, there's a couple of other options we have here. As I mentioned earlier, the IC does have some non-volatile memory. So, we can go into the MBM status, and you can see that I've committed 7 pages, and I have 19 pages remaining. So, the next time I plug this in, all of my calibration data, and all my settings will come back the same. So I won't have to go through that process again. If I wanted to, I could go back to the quick settings in calibration pages and send that data again, but since I haven't changed anything, that would just be burning up some free MBM pages.

If you really want to get into the low-level access, the command console gives you a terminal-like interface. And this is talking to the communications board. And through that, you can talk to the ZSSC IC. If I send it a V command, that'll just return the version of firmware that's running on the communications board.

ZMDIZSSC416X and ZSSC417X offer a variety of benefits in sensing applications, especially those in automotive designs. For more information, visit idt.com

SENT (Single Edge Nibble Transmission) is a unique serial interface/protocol originally targeted for automotive applications. Engineers are using this interface with sensors for applications such as throttle position, pressure, mass airflow, and high temperature. IDT provides sensor signal conditioners that function using the SENT interface.

The video reviews the three main SENT transmission protocols: fast channel read, short serial message format, and enhanced serial message format. It will cover the SENT signal's basic terms, definitions, and abbreviations, what is required to decode the SENT signal, and how to determine which SENT format applies to each application. It will cover the advantages of a SENT output vs. analog output and show an example of a sensor interface using SENT 3.0.

Related Resources

A brief introduction and overview of IDT's (acquire by Renesas) sensor signal conditioner evaluation kits. Evaluation kits generally consist of three parts: a communication interface board, a device board, and a sensor simulator board - all connected together. A sophisticated software GUI accompanies the kit, enabling an engineer to learn how to use the part rapidly, do quick prototyping, and practice calibrations.

Presented by David Grice, applications engineer at IDT. For more information about IDT's sensor signal conditioner products, visit the Sensor Signal Conditioner page.