Overview

Description

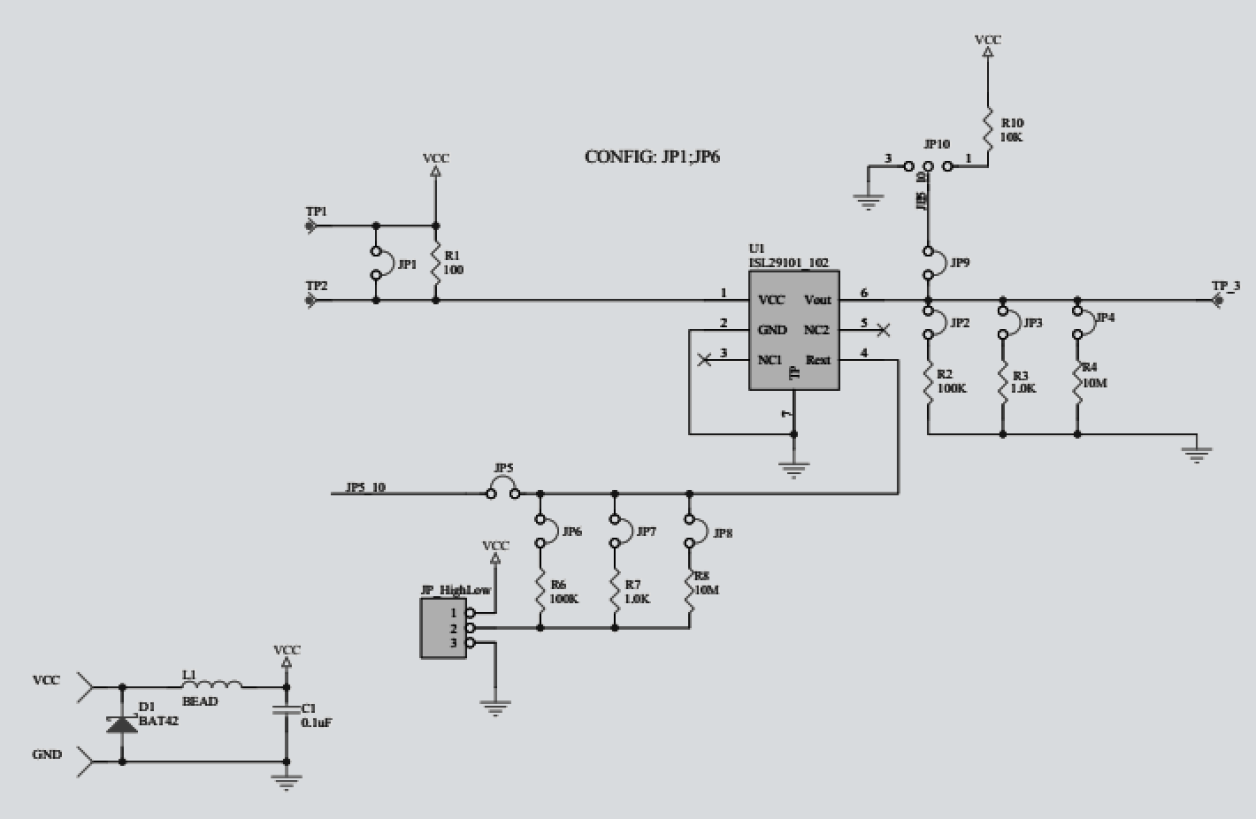

The ISL29101IROZ-EVALZ evaluation board is used to evaluate the performance of the ISL29101 low power ambient light-to-voltage optical sensor. The board is RoHS-compliant and is prepared to speed up part evaluation. The device and the evaluation board work from a 3V supply.

The ISL29101 is a low-light optimized analog output sensor. In normal operation, this sensor device is intended to be mounted behind a smoked glass/plastic bezel, which normally significantly attenuates received light. The ISL29101 typically saturates at full scale with an incident illumination of around 10,000 lux.

Features

- Low supply current

- 100kΩ output scaling resistor

- Fast response time

- Close to human eye response

- Good IR rejection

- Internal temperature compensation

- Operating temperature range -40 °C to +85 °C

- Pb-free (RoHS compliant)

Applications

Design & Development

Software & Tools

Software Downloads

Support

Support Communities

Get quick technical support online from Renesas Engineering Community technical staff.

Knowledge Base

Browse our knowledge base for helpful articles, FAQs, and other useful resources.