Overview

Description

RealityCheck™ AD is a ready-to-implement anomaly detection solution for monitoring factory and process-industry assets. It is a complete hardware and software solution for equipment monitoring and end-of-line testing for quality control. Users can deploy an edge node with one or more included sensors and immediately begin monitoring production equipment for unusual or anomalous functions. Just attach a Renesas edge node plus sensor, and automatically generate a baseline anomaly detection model. Over time, build your anomaly database and train additional models for detecting or predicting specific faults, or for predicting the remaining useful life of components. We offer a range of sensor options, including ones certified for corrosive or explosive environments.

Features

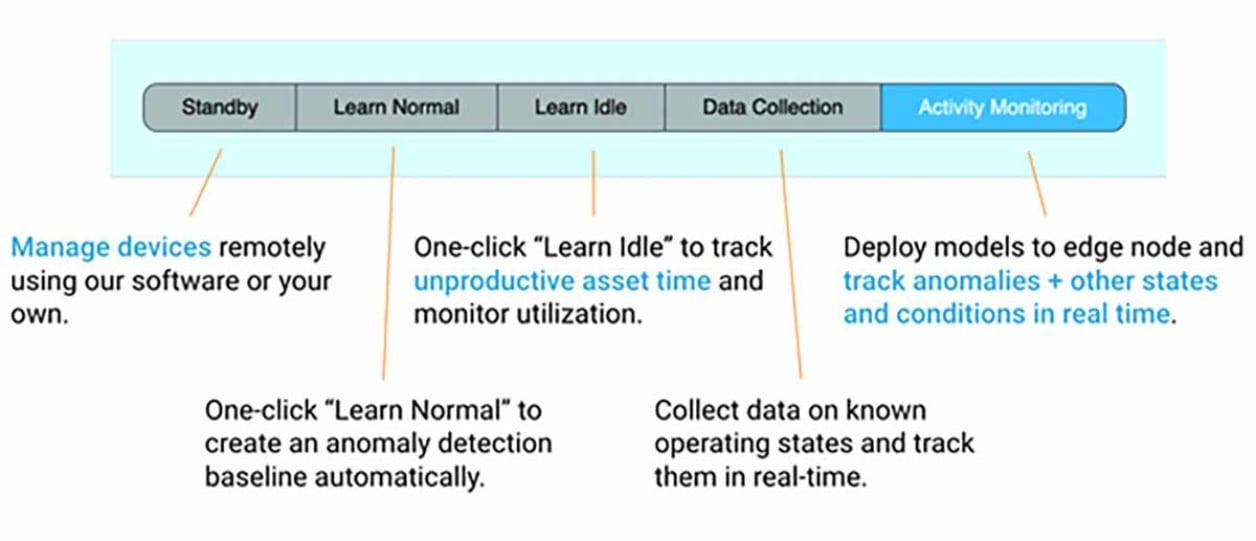

Renesas' Reality AI solutions combine advanced signal processing with artificial intelligence on inexpensive edge nodes. RealityCheck AD is a platform that enables Industrial IoT companies to:

- Easily deploy edge nodes and sensors, or reuse sensors that have already been deployed

- Start collecting data quickly and easily

- Automatically collect baselines and detect anomalies

- Collect and label anomalies for targeted detection for the future

- Predict the remaining useful life of components (filters, etc.), identify operational conditions, and detect abnormal conditions

- Provides an easy-to-use MQTT-based API for integration with dashboards and workflow systems

- Explosion-proof and corrosive environment sensors can be selected

Benefits

- Reduce costs associated with unnecessary downtime

- Improve quality by automated end-of-line testing

- AI engineering workstation for understanding models in time/frequency domains

- Full turnkey solution from sensor and edge node via AI modeling and dashboarding

Target Devices

Explore

Videos & Training

A look at how data-driven engineering tools can learn from examples to make a decision and ultimately be deployed automatically.

Problems RealityCheck™ AD Solves

- Unplanned downtime

- Equipment problems before scheduled maintenance

- Replaceable/Serviceable parts get used up prematurely (e.g. filter clogging)

- Unexpected problems

- Production bottlenecks

- Equipment idle when it should not be

- Information on specific production functions is difficult to obtain

- Quality inspections that are difficult or expensive to replicate

- Testing requires specific skills, training or extensive experience

- Testing that is subjective without reference to standards. "I know when I hear it"

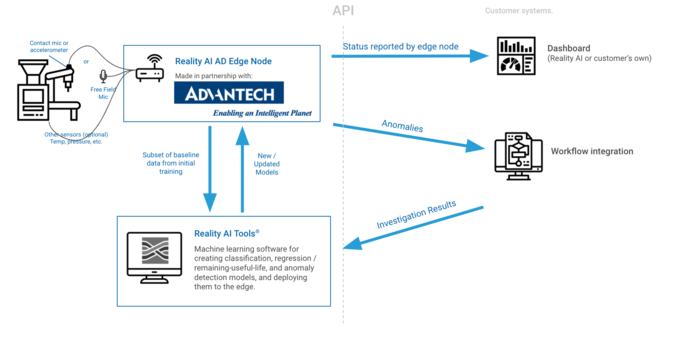

Architecture

The RealityCheck AD architecture is designed with flexibility, efficiency, security, and restoring force in mind. It allows easy integration of existing dashboard systems with workflow management systems. Data generated from edge devices can be easily integrated with these systems in a plug-and-play fashion. Additionally, there are options for explosion-proof and corrosive environments.

Resources

Support

Support Communities