パッケージ情報

| CADモデル: | View CAD Model |

| Pkg. Type: | 43-WLCSP |

| Pkg. Code: | |

| Lead Count (#): | 43 |

| Pkg. Dimensions (mm): | |

| Pitch (mm): | 0.65 |

環境及び輸出分類情報

| Moisture Sensitivity Level (MSL) | 1 |

| Pb (Lead) Free | Yes |

| ECCN (US) | EAR99 |

| HTS (US) | 8542.39.0090 |

製品スペック

| Lead Count (#) | 43 |

| Carrier Type | Tape & Reel |

| Moisture Sensitivity Level (MSL) | 1 |

| Pb (Lead) Free | Yes |

| Country of Assembly | Taiwan |

| Country of Wafer Fabrication | Taiwan |

| Additional Features | Capacitive down-converter |

| Bus Voltage (Max) (V) | 20 |

| GPIOs (#) | 2 |

| IOUT (A) | 10000 |

| Input Voltage (Max) (V) | 10.5 |

| Input Voltage (Min) (V) | 5 |

| Integrated step-down DC/DC Converter Channels (#) | 1 |

| MOQ | 7500 |

| Multi-Phase Support | fixed |

| Output Current Max (A) | 10 |

| Output Voltage (Max) (V) | 5.5 |

| Parametric Category | Charge Pumps (Inductorless) |

| Pitch (mm) | 0.65 |

| Pkg. Type | 43-WLCSP |

| Qty. per Reel (#) | 7500 |

| Qualification Level | Standard |

| Switching Frequency Range (Typical) (kHz) | 500 - 500 |

| Temp. Range (°C) | -40 to +85°C |

| Total step-down DC/DC converter channels (#) | 1 |

| VIN Range (V) | 5 - 10.5 |

| 掲載 | Yes |

DA9313 に関するリソース

説明

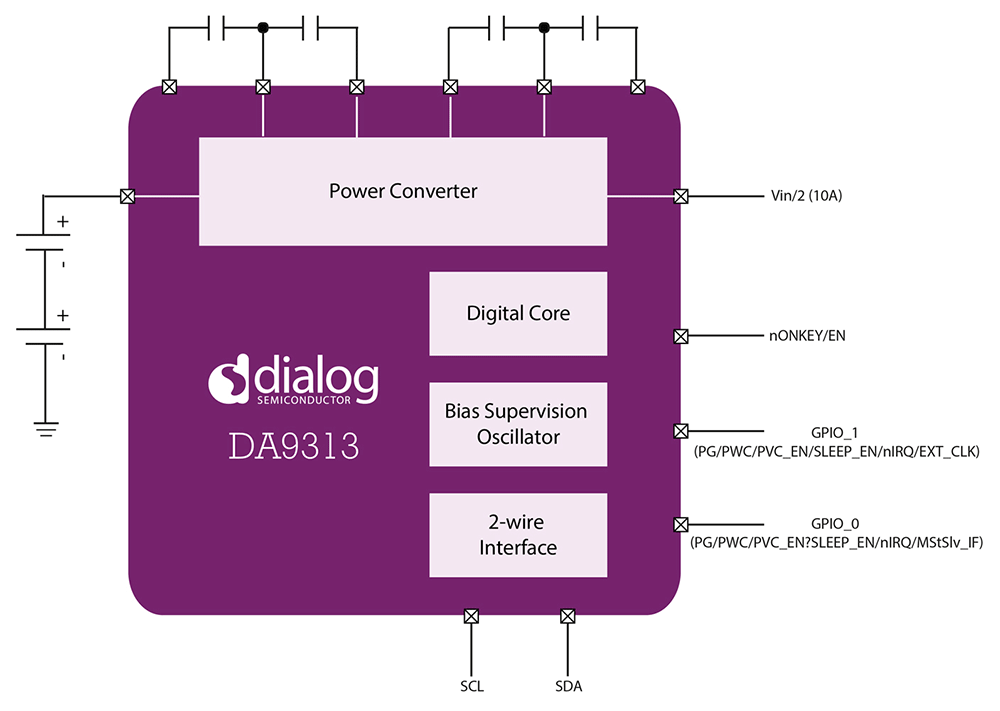

The DA9313 integrates the industry’s first inductor-less 10A power converter for best-in-class efficiency and offers master/slave operation for up to 20A of output current. The high current, inductor-less power converter offers incredible efficiency above 98%, powering greater than 50W in a less than 10mm2 package.

DA9313 enables applications to be powered with improved efficiencies and requires less volume compared to conventional high voltage direct conversion solutions. The fully integrated power converter halves the input voltage without the requirement for inductors and provides flat efficiency over a very wide range of output current.

Today’s competitor devices using charge pump technology to generate a regulated output voltage and have very limited output current capabilities.

Benefits

- 10A total output current from 5.0V to 10.5V

- Master/Slave configuration for up to 20A output current

- Enabling low profile externals (z-height ≤1mm) for high current application

- Solution size reduction in comparison to inductor based solutions

- Thermal hotspot reduction through ultra-high efficiency (98%)