Applications for capacitive touch interfaces have grown rapidly in recent years. Previously used mainly in smartphones and high-end digital consumer products requiring high functionality and an aesthetically appealing design, the use of touch interfaces has expanded over the past few years to include home appliances known as well as industrial automation and hygienic healthcare-related products. The advantages of capacitive touch interfaces, such as operability, durability and resistance to dust and moisture, make them attractive for use both in household and industrial equipment, and they are expected to achieve adoption in all types of devices moving forward.

Renesas has been involved in capacitive touch for many years. During this time there have been continual improvements to the performance and capability of the touch sensing unit used within Renesas MCUs. Now, we have introduced a new RA2L1 group of low-energy, general-purpose MCUs, which include a 48MHz Arm® Cortex®-M23 CPU with a new-generation Renesas Capacitive Touch Sensing Unit (CTSU2) which provides enhanced touch operability under a variety of conditions.

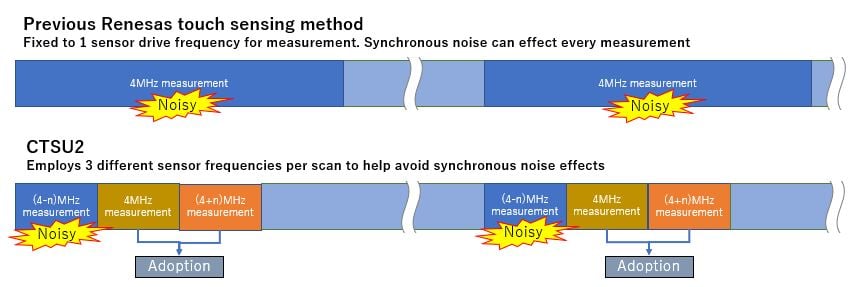

A key feature of CTSU2 is the improvement in noise immunity through the implementation of multiple sensor drive frequencies per touch channel. Previous generation Renesas touch sensing method utilized a single sensor drive frequency. In cases where noise synchronized with this drive frequency, sometimes significant issues in sensing (loss of sensitivity, spurious touches) were caused. In the CTSU2 for each touch channel, a center frequency and then lower and upper sensor drive frequencies are implemented. In this implementation, each of the frequency results is evaluated with the worst performance of the three discarded. The remaining two results are summed and used to produce a determination of touch ON/OFF judgment.

Figure 1. Scanning at multiple frequencies enables the MCU to reject synchronous noise

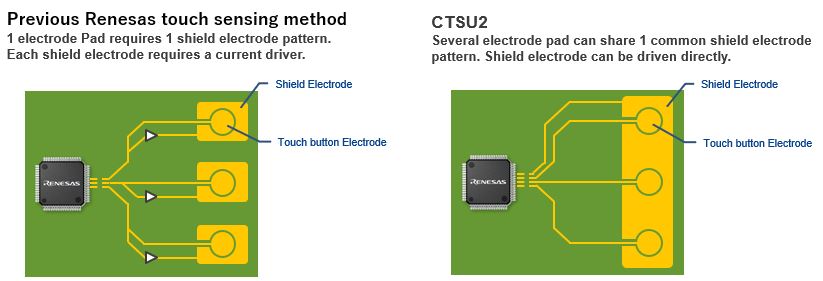

Another new feature is the addition of a driven shield that can help in challenging design environments. A shield electrode is used to help reduce parasitic capacitance around a touch sensor electrode. It can also help reduce environmental factors that may cause unwanted touch events. The technique requires that a second conductor, the shield electrode, be driven with a voltage equal to that being driven on the touch sensor electrode itself during measurement. This ensures no potential difference between the shield electrode and touch sensor electrode. Using this method, electrode pads can be shielded from noise impinging from either side and from below.

Figure 2. The addition of a driven shield that can help in challenging design environments

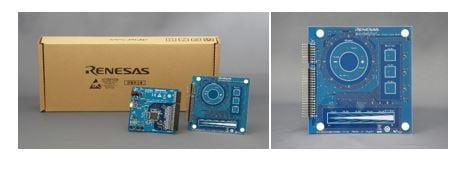

We have developed a capacitive touch evaluation system on the RA2L1, which is equipped with a 100-pin device. The kit includes a touch board (includes keys, wheel and slider interfaces) with shield electrodes.

Figure 3. RA2L1 Group Capacitive Touch Evaluation System

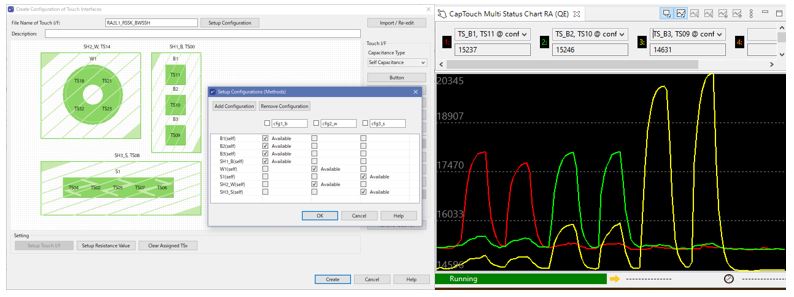

We also offer a tool called the QE for Capacitive Touch which is designed to help engineers quickly evaluate and tune hardware and software for optimum touch performance. QE for Capacitive Touch is simple to operate, yet very powerful and intuitive. Within this tool, there are various utilities available. Parameters such as reference values, thresholds and drift compensation can be modified on the fly through the Parameter Setting utility to tune each channel in real time. The measurement at each touch channel can be monitored graphically via this evaluation tool.

Figure 4. QE for Capacitive Touch parameter setting window

Please visit the links below for more details.

RA2L1 Microcontrollers

Capacitive Touch Evaluation System for RA2L1

QE for Capacitive Touch