Overview

Description

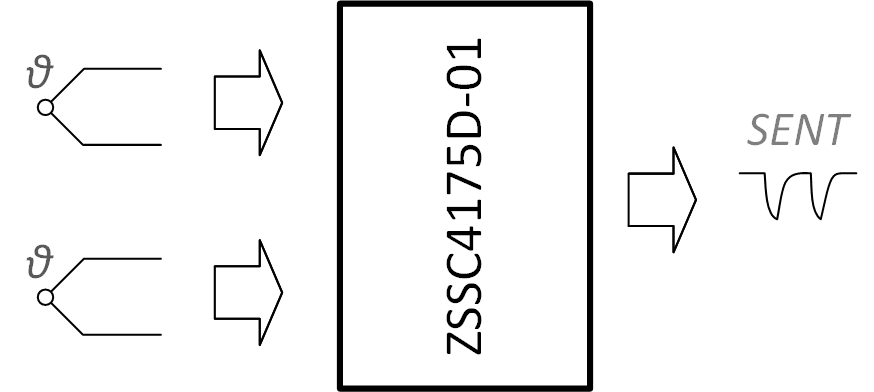

The ZSSC417xD provides precise amplification and correction of sensor signals, with possibilities for digital compensation of offset, drift, sensitivity, and nonlinearity. It features integrated non-volatile memory (NVM) for reliable automotive use and supports SENT for fast data transmission and One-Wire Interface (OWI) for easy calibration. Optimized for automotive environments, the ZSSC4175D offers robust protection, excellent EMC, and digital calibration, reducing costs and noise sensitivity while delivering superior performance. The ZSSC4175D-01 offers two independent measurements and linearization of N-type thermocouples. Cold-junction is compensated via internal chip temperature. Output data is transmitted via SENT interface.

Features

- Two differential thermocouple element inputs and an on-chip temperature sensor, available for cold-junction compensation and temperature output

- Operating temperature range: -40°C to 150°C

- Accuracy: Up to 5K at 1000°C hot junction

- Supports N-type thermocouples

- NVM memory for configuration, calibration data, and configurable measurement and conditioning functionality

- SENT output compliant to SAE J2716 JAN2010 (SENT Rev.3) and APR2016 (SENT Rev.4) standards

- Supports output of one or more thermocouple signals and product identification via a single SENT interface connection

- End-of-line calibration process minimizes production costs

- No external trimming or components required

- Qualified according to AEC-Q100 Grade 0

- Enhanced diagnostic features for sensor modules

Comparison

Applications

Documentation

|

|

|

|

|---|---|---|

| Type | Title | Date |

| Datasheet | PDF 626 KB | |

| Datasheet - Short-Form | PDF 167 KB | |

| End Of Life Notice | PDF 1.29 MB | |

| Guide | 7Z 1.21 MB | |

4 items

|

||

Design & Development

Software & Tools

Boards & Kits

Models

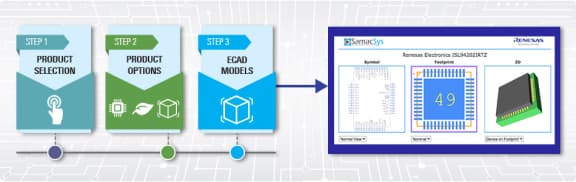

ECAD Models

Schematic symbols, PCB footprints, and 3D CAD models from SamacSys can be found by clicking on the CAD Model links in the Product Options table. If a symbol or model isn't available, it can be requested directly from SamacSys.

Support

Support Communities

Videos & Training

Modern vehicles are filled with complex sensor systems to achieve optimal performance and lower emissions. IDT's (acquired by Renesas) ZSSC416x and ZSSC417x family of sensor signal conditioner ICs are ideal for use in the engine and exhaust system. Sensing differential pressure at the mass airflow intake using a single IC attached to two sensors lowers power consumption and improves accuracy compared to traditional sensing systems. Manifold pressure and temperature sensing also benefit from using a dual input IC, with higher accuracy measurements resulting in a more optimal fuel mix.

The IDT ZSSC416x and ZSSC417x family of sensor signal conditioners provide a platform for measurement systems with improved accuracy, reliability, and performance with lower power consumption. The family of devices provides highly accurate amplification with integrated compensation, correction, and calibration, while also sharing a common four-millimeter by four-millimeter QFN package and toolset to reduce development and assembly costs.

Related Resources

Transcript

Modern vehicles are filled with complex sensor systems to achieve optimal performance and lower emissions. IDT's ZSSC416x and ZSSC417x family of sensor signal conditioner ICs are ideal for use in the engine and exhaust system. Sensing differential pressure at the mass airflow intake using a single IC attached to two sensors lowers power consumption and improves accuracy compared to traditional sensing systems. Manifold pressure and temperature sensing also benefits from the use of a dual input IC, with higher accuracy measurements resulting in a more optimal fuel mix.

High temperature sensing across the turbo-charger benefits from a simpler design and lower cost with both thermocouples connecting to the same IC. At the diesel particulate filter, IDT products enable more accurate measurements of filter saturation, resulting in less fuel waste for filter purging. Selective catalytic reduction adds urea to the exhaust to reduce harmful emissions. Improved measurement accuracy leads to better control of urea dosing, reducing urea overuse and refilling costs for the vehicle owner. By more accurately measuring temperature and pressure in the fuel line, the control unit can provide the best fuel/air mix, lowering emissions and improving engine performance.

Compared to traditional anemometers, the sensors used with IDT sensor signal conditioner products are more durable in the harsh environment of exhaust mass airflow measurements, leading to a more reliable, lower power solution. The IDT ZSSC416x and ZSSC417x family of sensor signal conditioners provide a platform for measurement systems with improved accuracy, reliability, and performance with lower power consumption. The family of devices provides highly accurate amplification with integrated compensation, correction, and calibration, while also sharing a common four-millimeter by four-millimeter QFN package and tool set to reduce development and assembly costs. For more information on IDT's ZSSC416x and ZSSC417x sensor signal conditioners, visit idt.com