Features

- Ultra-high precision front-end amplifier

- Zero-drift instrumentation amplifier

- Pin selectable 9 gain settings: G = 1 to 1,000

- Rail-to-rail input/output

- Differential output

- RFI filtered inputs improve EMI rejection

- Single supply: 2.5V to 5.5V

- Dual supply: ±1.25V to ±2.75V

- Low input offset: 5μV, Maximum

- Low input offset drift: 50nV/°C, Maximum

- High CMRR: 138dB, G = 100

- Low gain error: <0.4%, All Gains, Maximum

- Gain bandwidth: 2.3MHz

- Input voltage noise (0.1Hz to 10Hz): 0.4μVP-P

- Operating temperature range: -40 °C to +125 °C

Description

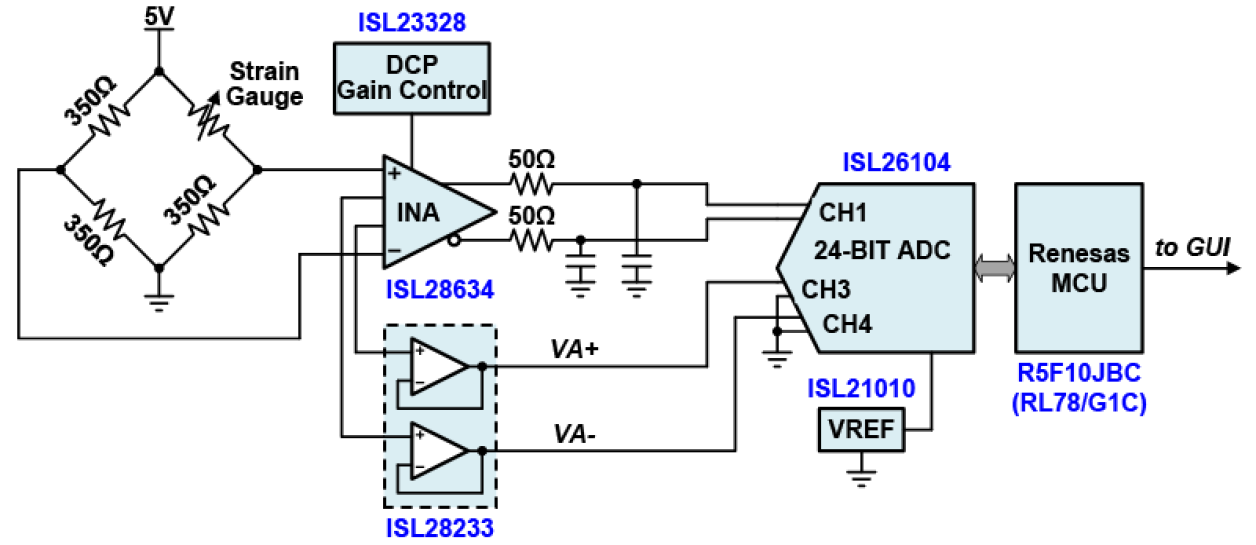

The ISL28634 is a 5V zero-drift rail-to-rail input/output (RRIO) Programmable Gain Instrumentation Amplifiers (PGIA). This instrumentation amplifier features low offset, low noise, low gain error, and high CMRR. It is ideal for high precision applications over the wide industrial temperature range. This in-amp is designed with a unique 2-bit, 3-state logic interface that allows up to 9 selectable gain settings. The ISL2863x differential output amplifier includes a reference pin to set the common-mode output voltage to interface with differential input ADCs.

Applications

- Pressure and strain gauge transducers

- Weight scales

- Flow sensors

- Biometric: ECG/blood glucose

- Temperature sensors

- Test and measurement

- Data acquisition systems

- Low ohmic current sense

Applied Filters: