As globalization and urban infrastructures advance, familiar products related to our daily lives are evolving to offer higher performance, better energy efficiency, and compact sizes. Power tools used in construction sites or DIY at home need to be smaller yet deliver higher torque, faster responsiveness, and longer battery operation with lower power consumption. Similarly, housing equipment and home appliances such as air conditioners, vacuum cleaners, and hair dryers emphasize quieter operation, faster rotation, and compact designs.

Central to achieving these innovations is the motor control system, the core of these products. Renesas' new RA2T1 microcontroller (MCU) directly addresses these challenges, particularly in advanced motor control techniques such as vector control.

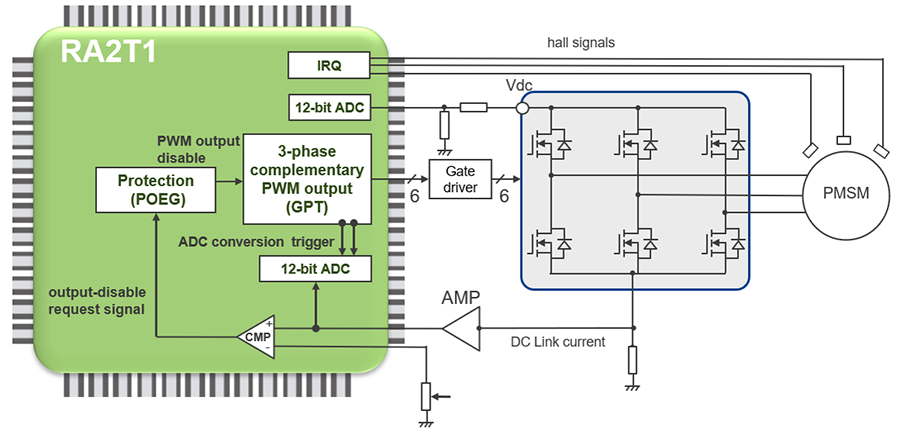

In power tools, brushless motors controlled via simpler methods like 120-degree conduction control face issues such as peak current and torque fluctuations. Transitioning to vector control, which is achieved by utilizing the RA2T1's peripheral functions, helps overcome these issues. This is achieved using a single-shunt current detection method that makes use of the existing DC link current sensing circuit, minimizing the need for additional components. Specifically, the RA2T1 provides an ADC conversion start request linkage function using a GPT timer, allowing current detection through a single-shunt resistor. Additionally, built-in comparator and port output enable for GPT (POEG) functionalities quickly shut off PWM outputs during abnormalities, ensuring system safety.

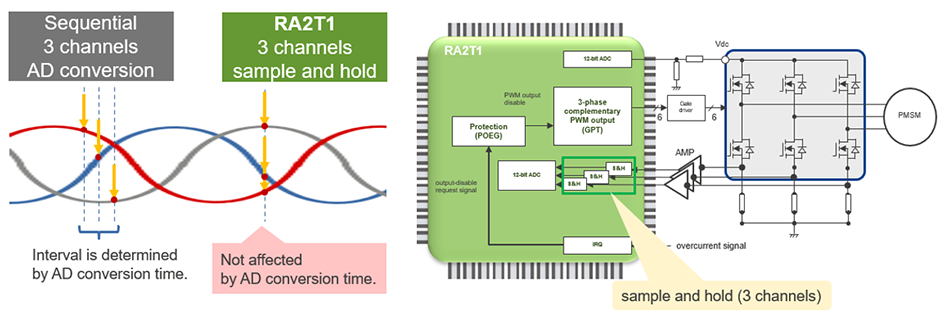

For fan applications in home appliances, quiet operation, power consumption, and high output are critical. One effective approach is to implement vector control that utilizes a 3/2-shunt current detection method, which uses the motor’s 3-phase current information. However, a single ADC module typically converts three channels sequentially, which can cause timing discrepancies in current measurement and affect the control performance. The RA2T1 MCU solves this by integrating a dedicated 3-channel sample-and-hold ADC circuit, ensuring simultaneous current sampling without measurement discrepancies. This is especially beneficial for high-speed motors operating at speeds over 100,000 RPM, enhancing overall motor performance and operational efficiency.

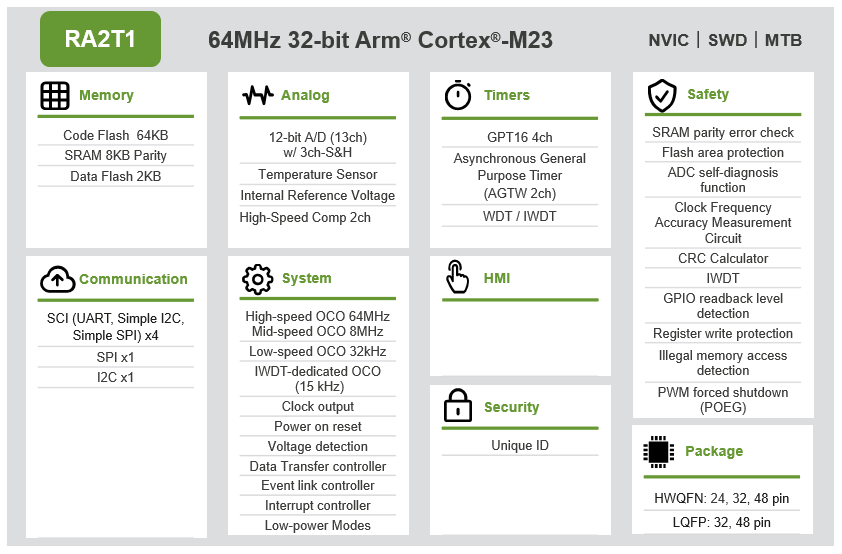

The RA2T1 MCU, powered by the Arm® Cortex®-M23 core with a 64MHz frequency—the highest within the RA2 series—is explicitly tailored for single motor control. Its optimized analog and timer functions, including a 12-bit ADC with dedicated 3-channel sample and hold circuits, two high-speed comparators, and GPT16 timer compatibility for single-shunt current detection, simplify system design and reduce overall component costs.

Additionally, RA2T1 comes in compact package options as small as a QFN24 (4mm x 4mm), operates over a broad voltage range (1.6V to 5.5V), and features a high-accuracy internal oscillator (±1.0% HOCO), further minimizing external components and overall cost.

Complementing its hardware, the RA2T1 offers extensive software and development support through tools like the Renesas Motor Workbench (RMW), Motor Control Kit (MCK), QE for Motor, and comprehensive sample programs, simplifying the evaluation and development of motor control systems.

For more information, visit the RA2T1 product page and download our detailed whitepaper for deeper technical insights.