What is the most important element for motor control using electronic devices? It is very difficult to narrow down the answer to one. This is because a motor control system is composed of many different elements, and if any one of them is missing, the motor cannot be controlled according to instructions. On the other hand, real-time performance is one of the key factors for motor control systems, as it can ensure precision, improve efficiency, and prevent failures. Read on to learn more about real-time performance, with a focus on the MCU.

Before we touch on real-time performance, electronically controlled motors are built with controllers such as MCUs/MPUs. These embedded processors have an architecture centered on CPUs and memory, execute instructions, and process data. In motor control, MCUs are often used in applications such as fans and pumps where the load fluctuations are small and the rotation speed does not fluctuate greatly, while MPUs are used in applications such as AC drives and AC servos in industrial equipment that control large motors and require high-speed control of rotation speed and torque.

Main Differences Between MCUs and MPUs

| MCU | MPU | |

|---|---|---|

| CPU Frequency | 8-bit to 32-bit CPU Several tens of MHz to several hundred MHz | 32-bit to 64-bit CPU Several hundred MHz to several GHz |

| Memories | Built-in flash memory and SRAM, and some products have the expandability of cache memory and external memory | Flash memory is external, SRAM is built-in, and it is easy to expand with external SDRAM, etc. Memory latency is improved with cache memory and Tightly Coupled Memory (TCM) for Arm® CPUs |

| Uses and Benefits | Extremely wide range of applications including consumer and industrial Cheaper and smaller packages than MPUs | For specific consumer and industrial devices that require high performance More expensive and larger packages than MCUs |

Real-time performance is to complete a specific process within a set time. In other words, what is important is that the processing time has little variation and the processing is always completed at the set time. If real-time performance cannot be guaranteed, not only will the motor not operate according to the command value, but in the worst case, the motor may lose control and lead to an accident.

With conventional MCUs, the CPU and built-in memory frequencies are close to each other, allowing them to estimate the worst processing time and easily guarantee the real-time performance. On the other hand, MPUs have a shorter control cycle to improve control accuracy and a faster CPU. When a program is executed from an external flash memory that is slower than the CPU, the memory speed becomes the limiting factor, causing the original performance to be unachievable. Therefore, the general countermeasure is to place programs in the built-in high-speed SRAM or TCM at startup to achieve high-speed operation. However, placing all programs in SRAM or TCM is difficult in terms of capacity, so ensuring real-time performance by utilizing the limited built-in memory is always a challenge for software developers of MPU-based motor control systems. In response to this issue, the RA8T2 MCU developed by Renesas combines the best features of MCUs and MPUs to make a significant contribution to the realization of highly real-time control systems. In terms of performance, it is equipped with a 1GHz Arm® Cortex®-M85 1GHz. Like an MPU, it has built-in cache memory, TCM, and SRAM, but what makes it significantly different from an MPU is that it is equipped with Magnetoresistive Random Access Memory (MRAM) for programs as an MCU. This MRAM operates at 100MHz, which is slower than SRAM or TCM, but its performance is significantly improved compared to external flash memory, making it easier to ensure real-time performance like that of conventional MCUs.

There are still challenges in motor control systems. In high-end motor control devices, other tasks such as system control and communication with other devices are added to the motor control, depending on the application. In other words, real-time processing of motor control and other non-real-time processing tasks must be executed in parallel. An effective way to solve this problem is to use a multi-core system, which is mainly used in MPUs.

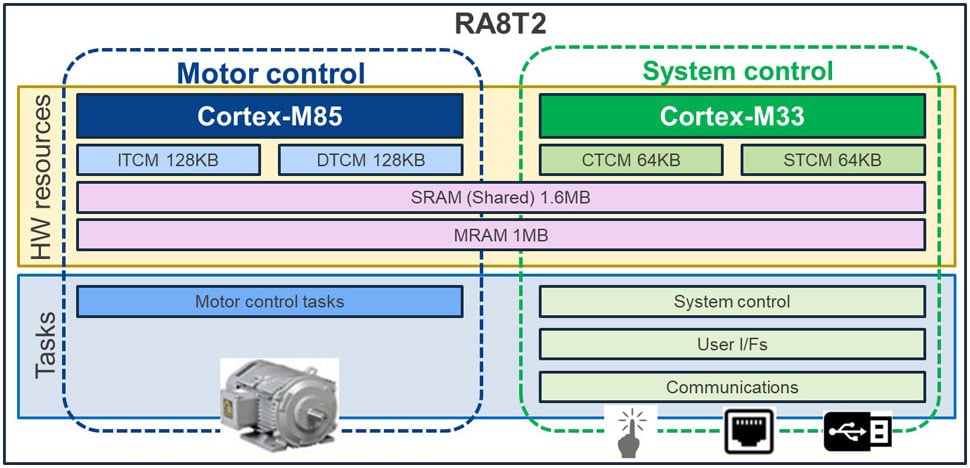

The RA8T2 offers an optional Cortex-M33 core in addition to the Cortex-M85, allowing users to build a dual-core system. As an example, let's consider the case where motor control processing is placed on the Cortex-M85 side (Figure 1). The Cortex-M33 side is assigned to system control, and its maximum operating frequency of 250MHz is sufficient for general system control. With this configuration, it is possible to separate motor control from system control, which is a non-real-time process, achieving complete parallel processing. This not only enables high real-time performance on the motor control side, but also improves the response and system quality on the system control side.

The MCK-RA8T2 is a kit equipped with motor control functions and EtherCAT® slave IFs. A BLDC motor is also included, allowing users to start evaluating as soon as they open the box. Also, a user's manual and quick start guide are provided, so it can be used for a variety of purposes, from initial evaluation to evaluation of user inverter boards, depending on the user's needs. Please try it out and experience the real-time capabilities of this new MCU.

Visit www.renesas.com/ra8t2 for more information on the MCU and its motor control kit.