Overview

Description

This solution aims to help customers implement the low-speed sensorless control function for IPM motor, which is difficult to develop, into their various equipment easily.

Suitable for applications that require torque and high efficiency at zero/low speeds.

In addition to the conventional high-voltage version (AC200V), a low-voltage version (DC24V) has been newly released. Please use according to the voltage of your motor.

Benefits of Adopting Whole Speed Range Sensorless Solution

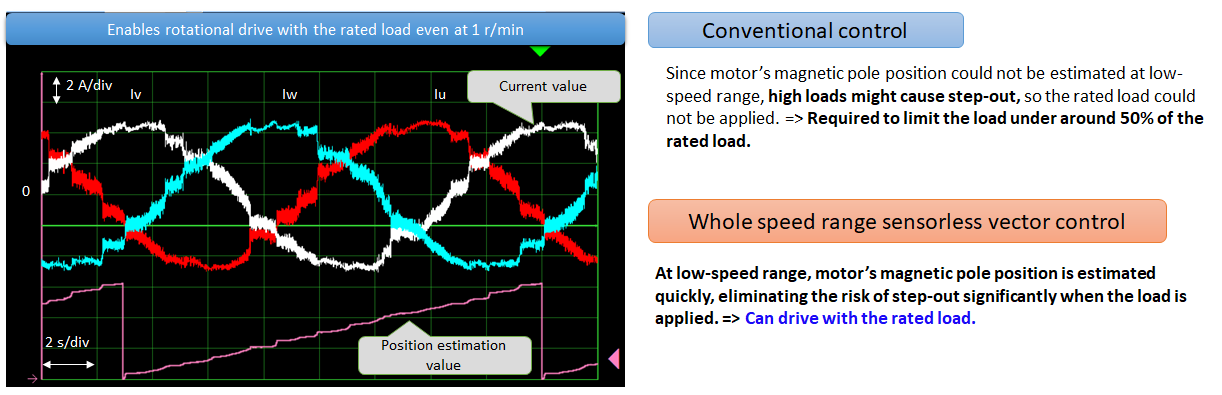

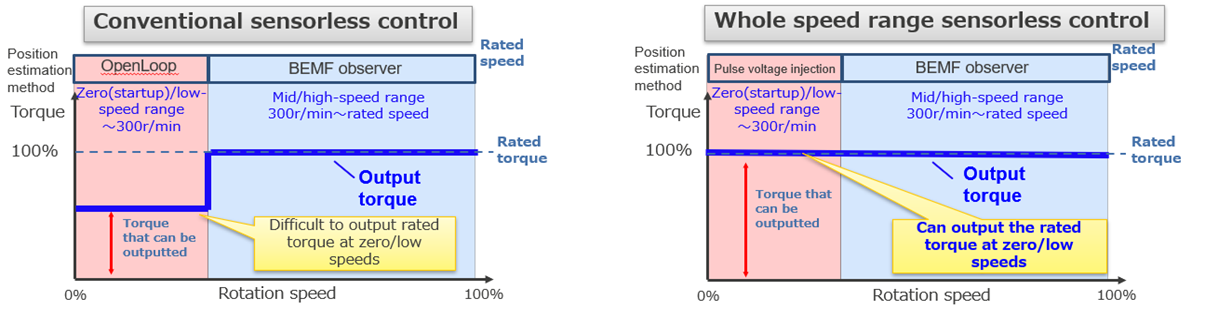

Torque Output at Zero/Low-Speed Range

By adopting position estimation with pulse voltage*1, it can output the rated torque at zero to low speeds (around hundreds of rpm), which conventional sensorless vector control*2 could not support.

*1: At zero/low speeds. At high speeds, drives by switching to position detection with BEMF observer.

*2: Renesas sample software “Sensorless Vector Control for Permanent Magnet Synchronous Motor (R01AN6307)”

@8-pole IPM, rated load (3.7Arms)

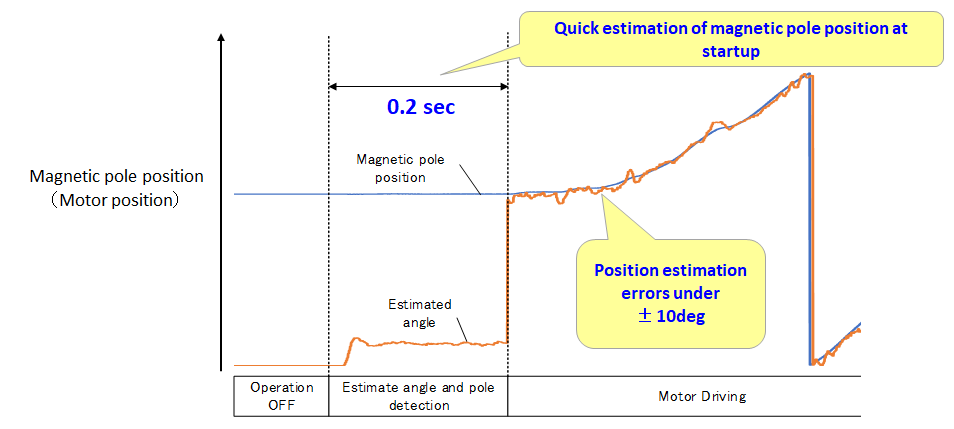

Improving Magnetic Pole Position Estimation Error and Reducing Estimation Time

Having the initial magnetic pole position estimation function, this solution enables quick position estimation within 0.2 seconds regardless of the motor position.

In addition, achieves magnetic pole position estimation errors under ±10deg (equivalent to GP INV).

⇒Enables quick startup and smooth motor control.

(starting from standstill)

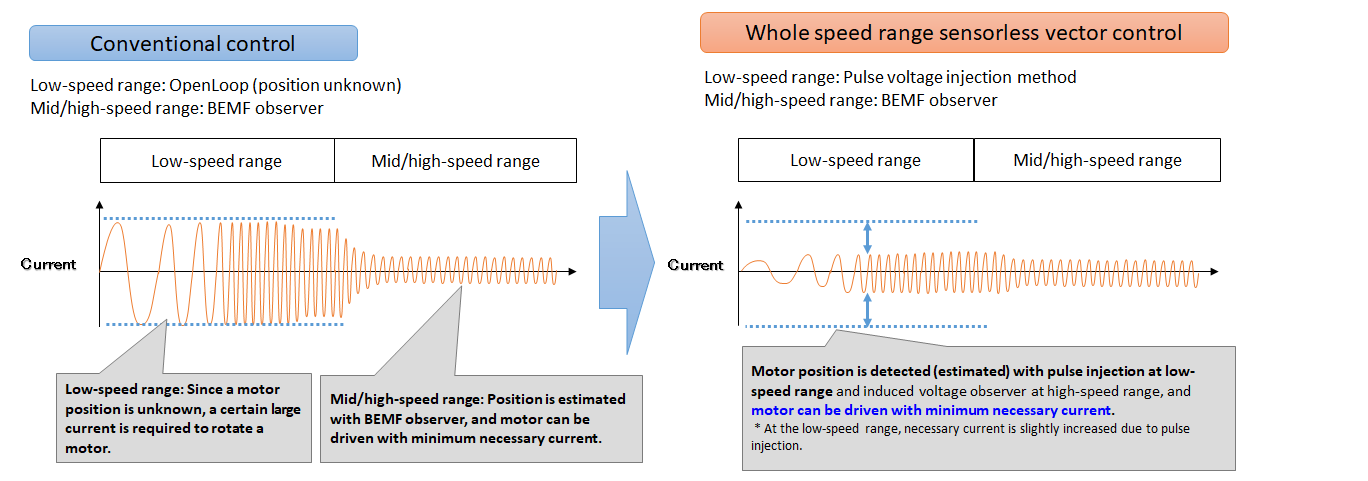

Optimizing Current Consumption

Since motor positions can be estimated even at the low-speed range, this solution enables motor drive with minimum necessary current according to the load at low-speed range, which the conventional sensorless vector control*1 didn’t support.

⇒Can improve energy efficiency and reduce current consumption, suitable for battery applications.

*1: Renesas sample software “Sensorless Vector Control for Permanent Magnet Synchronous Motor (R01AN6307)”

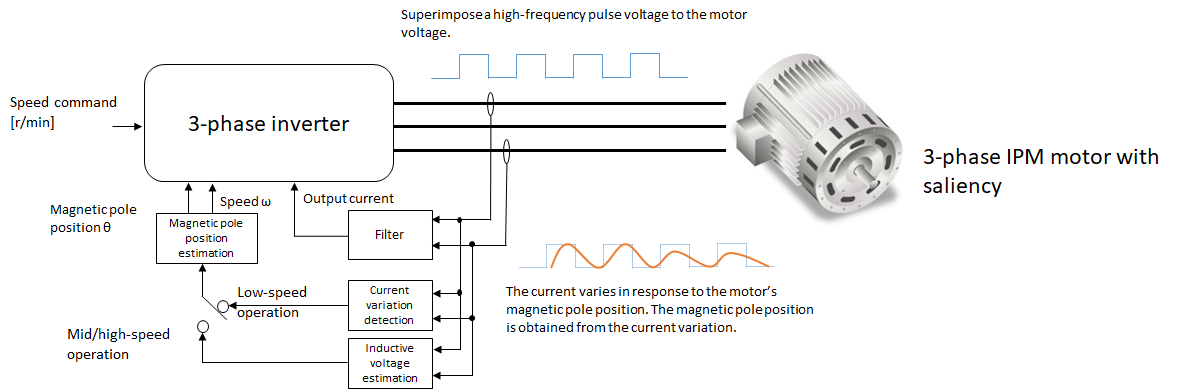

Control Algorithm

- Low-speed range: By injecting a high-frequency pulse voltage (around 1/2 of carrier frequency), the magnetic pole position and speed are estimated from the variation of the motor current.

- Mid to high-speed range: Stops injecting a high-frequency pulse voltage and switches estimation method of the magnetic pole position and speed to the method using inductive voltage, which is proportional to the rotation speed.

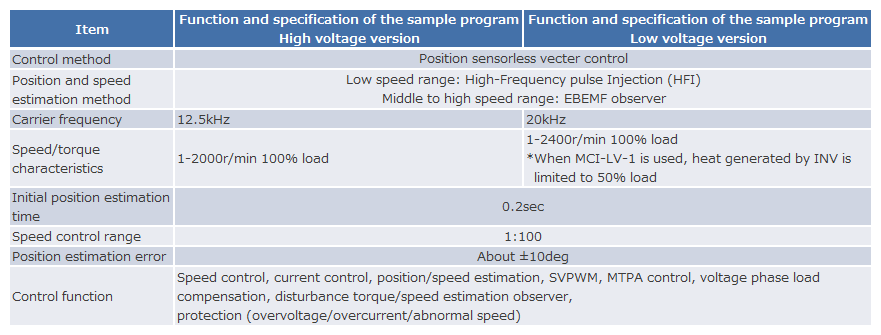

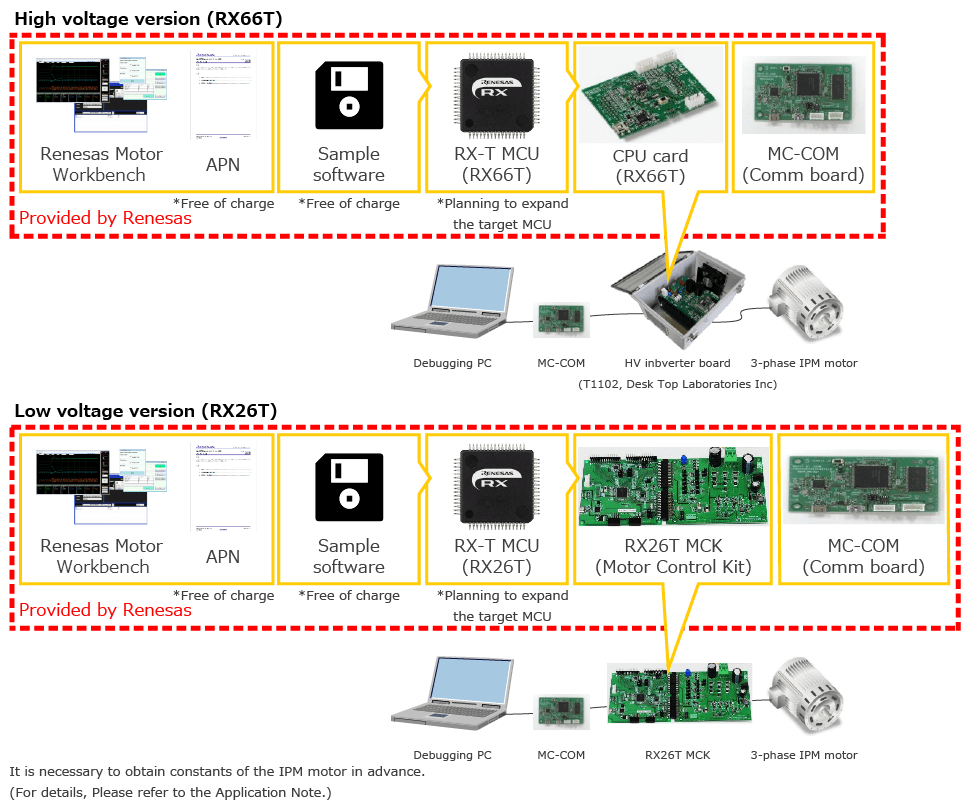

Function and Specification

Configuration of Whole Speed Range Sensorless Motor Solution

- Provide software and development support tools required for sensorless control for IPM motor over the whole speed range.

- Evaluation of 3-phase IPM motors with positive polarity and high-voltage versions can be performed by providing an IPM motor and a high-voltage inverter board.

Deliverables

High Voltage Version (AC220V, RX66T)

- Application Note

RX Family Sensorless Vector Control for IPMSM over the Whole Speed Range Rev.1.00 (PDF | English, 日本語) - Sample Software

RX Family Sensorless Vector Control for IPMSM over the Whole Speed Range Rev.1.00 (ZIP | English, 日本語) - CPU Card

RX66T CPU Card - Communication Board

MC-COM

Low Voltage Version (DC24V, RX26T)

- Application Note

Sensorless Vector Control for IPMSM over the Whole Speed Range for MCK (PDF | English, 日本語) - Sample Software

Sensorless Vector Control for IPMSM over the Whole Speed Range for MCK - Sample Code (ZIP | English, 日本語) - Motor Control Kit (MCK)

RX26T MCK - Communication Board

MC-COM

Features

- This solution achieves sensorless control over the whole speed range for salient-pole IPM motor (IPMSM).

- Can output the rated torque over the ranges from zero(startup)/low to mid/high speeds.

*In general sensorless motor control, it is difficult to output rated torque at zero/low speeds. - Since a position/speed sensor is not required, benefits cost/environment resistance/durability/miniaturization.

- Realizes sensorless vector control by detecting position with pulse voltage using saliency of IPM motor at startup and low-speed range, and with BEMF observer at mid/high-speed range.

⇒Suitable for 1) applications with load torque at zero(startup)/low speeds, and 2) applications with requirement for energy efficiency at low-speed range.

Comparison

Applications

Software

Software Downloads

|

|

|

|

|---|---|---|

| Type | Title | Date |

| Sample Code |

[Toolchains=CC-RX|V3.05]

ZIP

17.24 MB

日本語

Application:

Industrial

Compiler:

CC-RX

Function:

Application Example

IDE:

CS+ for CC, e2 studio

|

|

| Sample Code |

[Software=RX Smart Configurator|v2.15.0],[Toolchains=CC-RX|v3.04.00]

ZIP

15.65 MB

日本語

Application:

Industrial, Renewable Energy & Grid

Compiler:

CC-RX

Function:

Application Example

IDE:

CS+ for CC, e2 studio

|

|

2 items

|

||

Documentation

|

|

|

|

|---|---|---|

| Type | Title | Date |

| Application Note | PDF 3.01 MB 日本語 | |

| Application Note | PDF 2.73 MB 日本語 | |

2 items

|

||

Videos & Training

This solution enables customers to integrate a low-speed sensorless control function for IPM motors into a wide range of equipment. It is particularly suited for applications that demand high torque and efficiency at zero or low speeds.

Renesas provides two options: a high-voltage version (AC200V) and a low-voltage version (DC24V). Choose the version that matches your motor's voltage requirements.

Related Resources