Features

- Wide VIN range: 4.5V to 60V (65V abs max)

- Switching frequency range up to 200kHz

- 3-Phase drive for BLDC application

- Peak 1A/2A source/sink current with programmable drive strength

- Supports 8 adjustable levels of drive strength through hardware interface and 16 adjustable levels of drive strength through SPI interface

- Adaptive and adjustable dead time

- Fully integrated power supply architecture

- Two VCC LDOs allow for Sleep mode low IQ

- 500mA buck-boost switching regulator generates drive voltage (5V to 15V adjustable)

- 200mA adjustable output LDO for MCU supplies

- Flexible configuration

- 3-phase HI/LI mode and 3-phase PWM mode

- Support half-bridge, full-bridge configuration

- Three current sense amplifiers

- Four levels of sense gain setting

- Supports DC offset calibration during power-up and on-the-fly

- Supports both ground-side shunt sense or low-side MOSFET rDS(ON) sense

- Back-EMF sensing for BLDC sensorless operation

- Features both hardware interface and SPI interface

- Extensive fault protection functions (VCC UV, VM/VBRIDGE UV, charge pump UV, MOSFET VDS OCP, current sense OCP, thermal warning/shutdown, buck-boost current limiting, buck-boost OCP, buck-boost UV/OV)

- Supports reverse battery protection by additional external circuitry

- 7 × 7mm 48-VFQFPN package (0.5mm pitch)

Description

The RAA227063 is a smart gate driver IC for 3-phase Brushless DC (BLDC) motor applications. It integrates three half-bridge smart gate drivers that are capable of driving up to three N-channel MOSFET bridges and supports bridge voltages from 4.5V to 60V. Each gate driver supports up to 1A source and 2A sink peak drive current with programmable drive strength control.

Adjustable and adaptive dead-times are implemented to ensure robustness and flexibility. The active gate holding mechanism prevents a Miller effect-induced cross-conduction and further enhances robustness.

Parameters

| Attributes | Value |

|---|---|

| Function | 3 Phase BLDC Driver |

| Input Voltage Range (V) | 4.5 - 60 |

| Input Voltage (Max) (V) | 65 |

| VBIAS (Max) (V) | 60 |

| Quiescent Current | 20 µA |

| ISOURCE (Max) (mA) | 1000 |

| ISINK (Max) (mA) | 2000 |

| Internal Buck Regulator | Buck Boost 500mA |

| Gate Drive (V) | 15 |

| Internal Auxiliary Power | LDO (5V or 3.3V) 200mA |

| Adaptive Dead Time | Yes |

| VOUT Slew-rate Control | Yes |

| Charge Pump | Yes |

| Intern Gain Amplifiers | 3 |

| Internal Sample & Hold | Yes |

| Input Control | HI/LI or PWM |

| Input Logic Level | 1.5V/TTL |

| Advanced Fault Protection | Yes |

| Qualification Level | Standard |

Package Options

| Pkg. Type | Pkg. Dimensions (mm) | Lead Count (#) | Pitch (mm) |

|---|---|---|---|

| QFN | 7.0 x 7.0 x 0.75 | 48 | 0.5 |

Application Block Diagrams

| Cordless Brushless Drill Cordless brushless drill designs delivering power, precision, and connectivity. |

| Central Vacuum Cleaner BLDC motor central vacuum cleaner offers energy efficiency and remote control for enhanced convenience. |

| BLDC Traction Motor Drive A high-performance MCU with a 3-phase smart driver offers power efficiency, programmability, and sensor integration. |

| Highly Secure Drug Delivery System with NFC Authentication and Rich Connectivity Secure drug delivery system with precision dosing and safety features for proper medication and delivery. |

| Torque Control System Precision torque control ensures product quality using MCUs with high-precision AFE and reliable sensors. |

| High Power, Compact BLDC Motor Control Compact design with smart gate driver IC for 3-phase BLDC, GaN MOSFET and enhanced data communication. |

| Motor Control with Resolver Resolvers enhance motor control precision, reliability, and reduce costs in stepper and BLDC motor systems. |

Additional Applications

- E-bikes

- Battery powered tools

- Electric power steering

- Wheel chairs

- BLDC motor applications

Applied Filters:

Loading

Filters

Software & Tools

Sample Code

Simulation Models

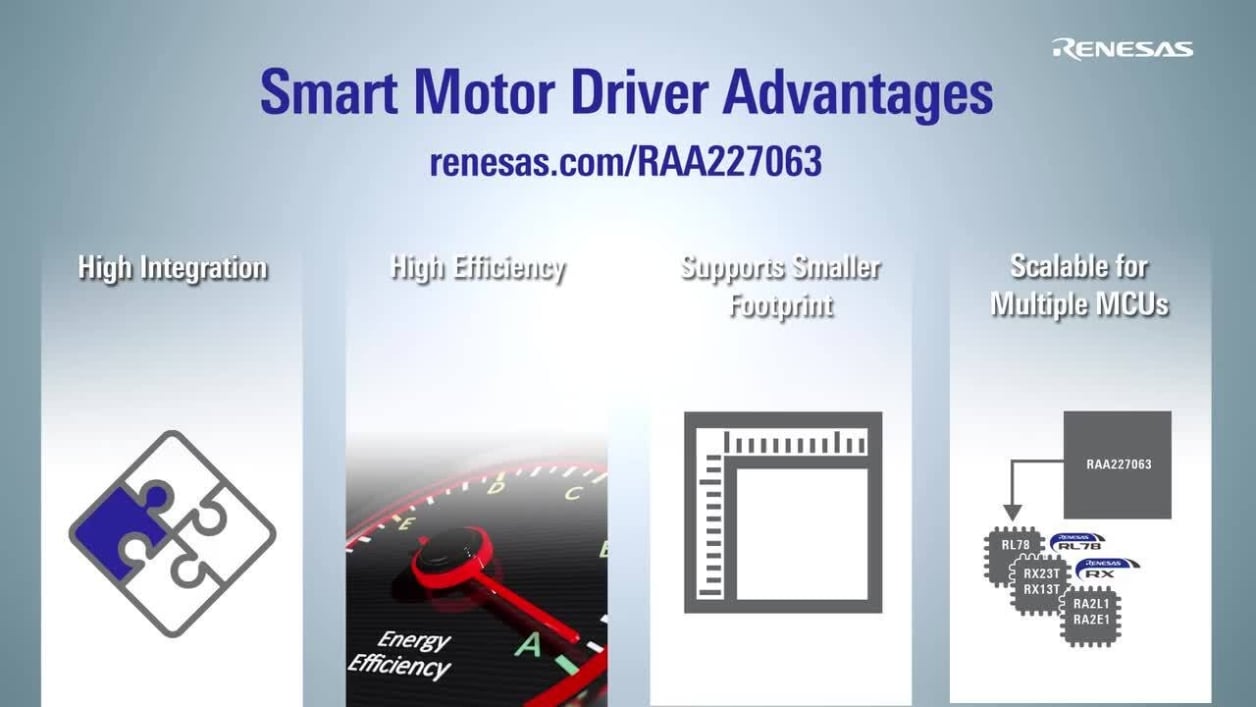

High-Precision, High-Efficiency Smart 3-Phase Driver Simplifies BLDC Motor Design