Did I have you at bacon? Drat! Now I have to continue…

Systems developers face many challenges, but very few of them strike as much fear into their hearts as much as needing the system to be compliant with an IEEE or ITU-T protocol, especially one that they haven’t worked with before.

This is because compliance in most cases requires the system developer to coordinate the actions of several integrated circuits and even scarier, software, to meet the requirements of the IEEE standard or ITU-T recommendation. These integrated circuits likely come from different suppliers and the software from one or the other of those suppliers, a third-party developer or their own internal team. Our intrepid system developer no doubt anticipates the discussions where each of them will point to one of the others as the reason why compliance wasn’t or couldn’t be achieved. I can almost hear the collective sigh of recognition.

This all too common situation inevitably leads to the question of how the system gets tested to prove compliance. What’s the test plan and methodology? What equipment is needed?

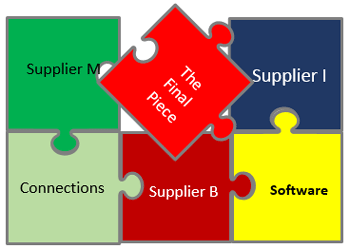

Reference designs are an extremely useful way out of this dilemma. If those several integrated circuit suppliers can work together and provide a tested, documented solution that includes compatible ICs, schematic guidelines and software examples. It can also provide a compliance report that not only proves the solution works, but also shows exactly how to perform the testing and with what equipment.

When a reference design can be found, it can be a panacea for a system developer. They may even consider selecting Supplier I instead of Supplier X if Supplier I has a reference design that will smooth the way through the many issues that can crop up in developing compliant systems.

For integrated circuit suppliers to cooperate with one another in this way requires a few preconditions:

- The suppliers must have between them all the applications expertise to develop and demonstrate compliance with the required specification

- The suppliers should have product portfolios that are complementary

- The suppliers all have or are willing to establish relationships with the targeted end-customers

If the suppliers jointly have the applications expertise, they can often work with the contracted boards and software developers for those parts of the solution. They just need to be able to provide clear and accurate guidance to those contractors.

If suppliers don’t have complementary product lines, then any customer engagement will result in introducing a competitor into an opportunity, opening the door to design your silicon out. Even if the product line overlap is not related to the reference design, it’s still a cause for hesitation at most suppliers.

Finally, the system developer wants to know that they can engage with any of the partners in the reference design and all partners will work together cooperatively to address any implementation or testing issues that come up. No finger-pointing or worse – refusal to engage in discussions – is allowed.

In addition to designs related to system synchronization or timing, Renesas has a deep store of applications expertise, with over 100 person-years of experience implementing integrated circuit solutions for SyncE and IEEE 1588. Renesas has very complementary product lines to most PHY and Switch IC vendors. Unlike other timing suppliers, Renesas does not have competing PHY and Switch products in our portfolio. Finally, Renesas has the worldwide sales and support force to engage anywhere customers all over the world.

So you can see that Renesas has all the ingredients and the continued commitment to generate the reference designs that will help save your bacon someday.

Check out the complete Renesas timing products portfolio at renesas.com/timing.