About This Video

ZSSC416X and ZSSC417X provide highly accurate amplification and calibrated correction of sensory data for resistive bridge and voltage source sensors. The family features SENT 3.0-based ICs and is designed for use in automotive applications. With available diagnostic info, rugged circuit protection, and excellent electromagnetic compatibility.

The family aids designers by lowering power consumption, reducing component count, and saving time spent calibrating sensors. Additionally, the availability of dual-bridge inputs also reduces system complexity and footprint. All of these are important considerations in modern automotive applications where power and space come at a premium.

Related Resources

Transcript

I'm Chris Anderson at the EEWeb Tech Lab, and today, we'll discuss ZMDIZSSC416X and ZSSC417X family of sensor signal conditioners. ZSSC416X and ZSSC417X provide highly accurate amplification and calibrated correction of sensory data for resistive bridge and voltage source sensors. The family features SENT 3.0-based ICs and is designed for use in automotive applications. With available diagnostic info, rugged circuit protection, and excellent electromagnetic compatibility.

The family aids designers by lowering power consumption, reducing component count, and saving time spent calibrating sensors. Additionally, the availability of dual-bridge inputs also reduces system complexity and footprint. All of these are important considerations in modern automotive applications where power and space come at a premium.

The ZSSC416X and ZSSC417X feature a widely programmable gain amplifier, a 12 to 18-bit EDC, an integrated temperature sensor, non-volatile memory to store calibration coefficients and configuration data, and a 16-bit risk MCU, that uses the calibration data and temperature measurement to compensate for offset, thermal drift, sensitivity variations, and non-linearity. End-of-the-line digital calibration over the I2C or one-wire interface improved calibration accuracy and reduces assembly cost and complexity.

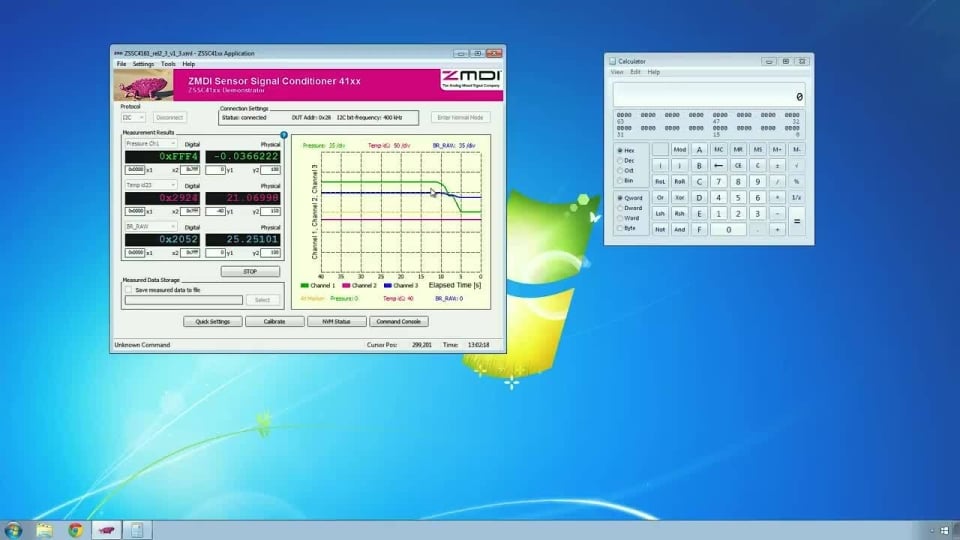

So, on the evaluation kit for the ZSSC family, we have the communications board, which interfaces between the PC and the IC, we have the actual ZSSC board, which houses the IC, and that's sitting inside the socket. What I really like about this board, is ZMDI gives you access to all the pins, so you can plug in your own sensors, and you get access to the temperature sensor, as well as any other pins that you need to. So, you can really evaluate whether or not this is suitable for your application.

The third board acts as a pressure sensor. It's really just a potentiometer, though. On the software side, on the first time you'll come in and you'll load an XML file, and that will load in some basic parameters. And you can check those in the quick settings and then load those into RAM, write all to RAM. And then you'll want to come in here and calibrate your sensors. I've already done that for both the pressure and the temperature sensor. So, those are good to go. I've already written those out. And you can also see that I'm actually running software now, so if I adjust the potentiometer, or the pressure sensor, you can see in green, that's the calibrated measurement, and in blue, the raw measurement. So, you can see those adjusting up and down.

The pink graph is the internal temperature sensor. So, if I put a heat gun to that, you can see the temperature rise up. Now, I'm going to go ahead and stop. Now what we want to do is grab this hex version of the temperature data, and actually, we're going to run it again, so that we can get a fresh version, because it's been cooling off, of course. So, if we say, it's sitting at about 0X, 2E25. So, plug that into the calculator. Now, the I2C data, is 15-bit and the SENT data is 12-bits. We're going to divide this by eight, and then we're going to go compare this to what we see over the SENT interface. So, if we enter normal mode, this additional window will pop up, and we're going to try to freeze IDE23, as it comes down through the SENT data.

So, we can see 05BE. Which isn't far off from 5C4. So, that's just a different representation of the data, and you can see some other channels here for the SENT load data, as well.

Now, there's a couple of other options we have here. As I mentioned earlier, the IC does have some non-volatile memory. So, we can go into the MBM status, and you can see that I've committed 7 pages, and I have 19 pages remaining. So, the next time I plug this in, all of my calibration data, and all my settings will come back the same. So I won't have to go through that process again. If I wanted to, I could go back to the quick settings in calibration pages and send that data again, but since I haven't changed anything, that would just be burning up some free MBM pages.

If you really want to get into the low-level access, the command console gives you a terminal-like interface. And this is talking to the communications board. And through that, you can talk to the ZSSC IC. If I send it a V command, that'll just return the version of firmware that's running on the communications board.

ZMDIZSSC416X and ZSSC417X offer a variety of benefits in sensing applications, especially those in automotive designs. For more information, visit idt.com