The Internet of Things (IoT) is destined to transform not only our daily lives but the entire fabric of human society. From smart homes to the factories of the future, the number of connected devices continues to increase at a rapid rate. Artificial Intelligence (AI) coupled with the Internet of Things has improved human-machine interactions and enhanced data management and analytics. To improve system efficiency and decision-making, we now have the ability to run AI models locally on the edge or endpoint. However, with resource-constrained edge devices, the training of the machine learning models in most still needs to happen in the cloud. The trained models can then be deployed at the edge for execution. This approach benefits from the power of the cloud (training) and the low latency on the edge (faster execution).

Endpoint AI employs intelligent functionality at the edge of the network. In other words, it transforms the IoT devices that are used to compute data into smarter tools that showcase AI features. This equips them with real-time decision making capabilities and functionalities. The goal is to bring Machine Learning (ML) based intelligent decision making physically closer to the source of the data. In this context, AI ML embedded systems shift to the endpoint. Endpoint AI spans a wide range of applications, including industrial, consumer, healthcare, transportation, manufacturing, retail, and many more.

Defining the Value Proposition

The value proposition of Artificial Intelligence of Things (AIoT) is to be able to deploy greater intelligence at the edge to ultimately achieve greater agility. Endpoint devices are at the very edge of the network, precisely at the source of the data, which allows for faster and often more accurate responses while saving costs on unnecessary data transmission, latency and data-in-motion security risks.

The initial step is to recognize the issue and rely on the related information from the system to analyze it and take the appropriate decision. Information/Data then needs to be sorted and grouped to investigate ways to extract specific features that benefit and train the required AI/ML models. AI models running at the endpoint are capable of providing better insight and solutions to complex real-world problems. Embedding AI at the endpoint allows developers to take advantage of powerful machine learning models without having to rearchitect their system completely. In a way, the endpoint is the final step of a process where the result is passed to a process, system or human who then interprets and reacts to the input.

Data in Its Entirety

Ultimately, it’s all about the data and its quality to achieve the best outcome while solving a real-world problem using AI. There is a need to employ an integrated approach of extracting insights from the ever-increasing volumes of data using various scientific methods, algorithms and processes. It is driven by software that recognizes hidden patterns within the unprocessed data. These valuable insights facilitate in supporting corporate decision making by interpreting business predicaments in an analytical way to transform them into viable solutions.

When critical thinking encounters machine learning algorithms, data science aids to achieve better insights, guide efficiency efforts and inform predictions. The goal is for businesses to benefit from Data Science to make progressive decisions and create more innovative products and services. One of the key requirements is the development of AI/ML models utilizing techniques such as TinyML to be able to run such models on resource constraint endpoints. This method simplifies building machine learning models for embedded hardware and relies on relevant AI tools for machine learning data acquisition, with wizards leading you through the process of training, testing and exporting models.

The Initiation Process

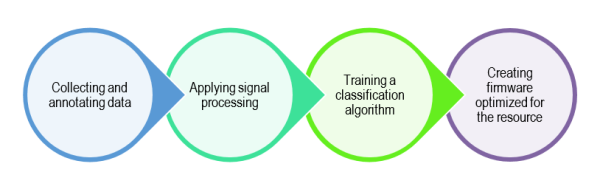

A specific skill set is required to build an endpoint AI application which includes data science, hardware engineering, embedded programming, software engineering, machine learning techniques, as well as domain expertise about the application that is being developed. The major steps required to build the application can be broken into four parts, cited in the figure below.

Case Study: Predictive Maintenance

Predictive Maintenance (PdM) is a time-based data-driven approach that employs machine learning and predictive data analytics to monitor a range of equipment conditions that could highlight a potential system or equipment failure. Predictive maintenance that relies on various machine learning models allows developers to run automated data processing on a given data set. The trained model assists in detecting potential equipment failures so that recommended action can be executed in real time. In other words, predictive maintenance can be identified as a set of artificial intelligence techniques and machine learning/TinyML algorithms. These algorithms are generally fed with data gathered in the process of monitoring specific machinery and are used to train models that can anticipate possible anomalies.

An instance of a key use case for predictive maintenance can be seen in different types of motor control applications across building automation, appliances or industrial automation. Deployment of PdM for a motor control application can help to detect and manage failures related to motor vibration as electric motors create a vibration frequency or signature. Once a baseline is established, the pattern recognition can identify if there are any imbalance, misalignment, looseness, or bearing failures in the motor efficiency and safety of its operation and keep the overall system stability by reducing the maintenance and the service cost at the same time. Some of the failures in motor-driven applications are related to vibration anomalies and unbalanced load. Preventing such anomalies leads to avoiding system failures and overheating that may eventually cause insulation failure of the motor windings, costly repair and significant downtime during replacement. This could all be prevented by deploying AI-based predictive maintenance solutions.

Designed for motor control applications targeting smart homes, industrial automation and building automation, the Renesas RA6T1 Group MCUs offer a rich set of peripheral functions and AI-based failure detection that meet the unique needs of motor control applications ranging from home appliances, HVAC, solar inverters to AC drives.

Based on the Arm® Cortex®-M33 core, the RA6T2 32-bit MCUs operate at 240MHz and feature a rich collection of peripherals optimized for high performance and precision motor control. The integrated peripheral functions with high-speed analog significantly reduce bill of materials (BOM) cost while boosting motor control performance. For example, in a single sensorless mode using the field-oriented control, using the RA6T2 MCU can simultaneously control up to two brushless DC (BLDC) motors.

In addition, Renesas incorporates a dedicated toolchain for TinyML applications to add enhanced failure detection to the RA6T2CU-based system, offering customers an intelligent, easy-to-use, and cost-effective sensorless motor system for predictive maintenance. Such TinyML-based AI models can help detect potentially detrimental anomalies in motor systems earlier and more accurately to help customers improve their predictive maintenance processes and reduce maintenance costs.

Renesas provides a complete development kit based on the RA6T2 that comprises all the essential components and software building blocks to quickly build a predictive maintenance enabled motor control solution:

- RA6T2 has PWM timers and analog functions on a single chip, which are the best choice for motor control. RA6T2 can control up to two motors, with rich analog features.

- Evaluate and debug motor control applications by using a complete motor solution. The hardware kits (MCK-RA6T2 ) and evaluation tools Renesas Motor Workbench (RMW) that are together with the PdM solutions are offered by Renesas as a reference solution for evaluation and debug purposes enabling real-time analysis and tuning of the overall system.

MCK-RA6T2 (Complete Motor Control Development Platform)

Renesas is capable of promoting highly efficient AIoT solutions addressing a wide range of applications, including voice, vision and real-time analytics. Together with its partners, Renesas offers comprehensive and highly optimized TinyML endpoint-capable solutions encompassing hardware, software and AI tools relevant for engineers building AI-based solutions in no time.

The impact of AI isn’t just in the cloud; it will be everywhere and in everything. Localized on-device intelligence, reduced latency, data integrity, faster action, scalability, and more are what endpoint AI is all about, making the opportunities in this new AI frontier endless. So now is the time for developers, product managers and business stakeholders to take advantage of this huge opportunity by building better AIoT systems that will solve real-world problems and generate new revenue streams.

We welcome you to start your own development with Renesas products and support in creating new applications and business streams that were not possible before. Unleash your imagination as what is to come is beyond expectations.

For more information, visit Renesas Artificial Intelligence | Renesas.