Overview

Description

Features

- Wide input range: 4.5V to 60V

- High light-load efficiency in pulse skipping DEM operation

- Programmable soft-start

- Optional DEM/CCM operation

- Supports prebias output with SR soft-start

- External frequency sync

- PGOOD indicator

- OCP, OVP, OTP, UVP protection

- Back biased from output to improve efficiency

- Small and compact designs

Applications

Applications

- PLC and factory automation

- Amusement machines

- Industrial equipment

- Security surveillance

- Server and data centers

- Switchers and routers

- Telecom and datacom

- LED panels

Documentation

|

|

|

|

|---|---|---|

| Type | Title | Date |

| Manual - Development Tools | PDF 718 KB | |

| Datasheet | PDF 2.49 MB | |

2 items

|

||

Design & Development

Software & Tools

Videos & Training

Learn how the ISL8117/A buck (step-down) PWM controller reduces design time and takes up less real estate on the board than competing devices.

Transcript

ISL8117/A 60V Synchronous Buck Controller

Welcome to the ISL8117 and ISL8117A 60V synchronous buck controller product training.

Today, we are here to introduce Intersil’s innovative high voltage controller. Before we go into the product discussion, let me quickly go through the analog controllers that Intersil has to offer. We offer a large selection of product with a variety of functional and protection features to address different customers’ needs.

Here is a quick table of Intersil’s analog controller products in different categories. This is just a sample of products available in each product category. For example, we picked the ISL6446 in the dual output category, but we do have multiple solutions in that category. We’ve also included details on the ISL8117 60V synchronous buck controller, and the ISL8117A 60V synchronous buck controller with external compensation.

ISL8117/A: An Innovative 60V Sync Buck Controller

Here is the brief introduction of the part we are going to talk about, the ISL8117/A. With this part, we are looking to simplify the controller based power design. The ISL8117/A offers reduced design time and solution cost; it is easy to use, thus simplifying the design process; and, it takes up less real estate on the board with 40% fewer external components than competing devices. The ISL8117/A also offers up to 98% efficiency and 1.5% output voltage accuracy.

ISL8117: High Voltage 60V Buck Controller

Let’s have a quick look at what the ISL8117 has to offer and what that means to end customers or applications. In high voltage applications where a lower output voltage is required, designers have traditionally relied on modules that increase system cost, or two stage DC/DC solutions that increase solution footprint and complexity. The ISL8117 controller offers a cost-effective and reliable alternative for applications where the VOUT to VIN ratio is low. The ISL8117 uses valley current mode modulation with adaptive slope compensation to enable stable operation for a wide range of VIN and VOUT combinations, with no external compensation required.

Other key features and specifications include:

- Wide input voltage range of 4.5V to 60V that covers all standard input rails including 5V, 12V, 24V, 36V, 42V, and 48V

- Wide voltage output range that is configurable from 0.6V to 54V

- Smallest min on time in the market, which enables a very low duty cycle power supply and eliminates the need for a two stage solution in many applications

- Programmable 100kHz to 2MHz switching frequency can be synchronized to reduce radiated system noise and avoid beat frequency issues

- Complete fault protection for long term reliability including overvoltage, undervoltage, overcurrent, and overtemperature

- High current FET drivers and DEM mode operation ensures efficiency at all load levels

- Adjustable soft-start with pre-bias support enables the sequenced startup of multiple ISL8117 controllers

Target applications for the ISL8117 include:

- After market automotive electronics

- Amusement machines

- Security surveillance

- Factory automation/ATM machines

- 48V telecom and networking systems

ISL8117A: 60V Buck Controller w/External Compensation

The ISL8117A allows for external compensation, as compared to the internal compensation used in the ISL8117. The differences between the ISL8117 and ISL8117A are covered in the next slide.

ISL8117 vs. ISL8117A

The CLKOUT pin of the ISL8117 is replaced by a COMP pin in the ISL8117A.

The COMP pin brings wider flexibility in compensation design.

The COMP pin gives the user wider choices of external components.

All other functions remain the same except the pin configuration.

The ISL8117A is targeted for power module customers.

Valley Current Mode with Adaptive Compensation

Here, we show a comparison of different modulator schemes used in high voltage to low voltage power conversion. When the upper MOSFET turns on, nodes can be very noisy in terms of voltage and current. The turn ON noise limits the practical minimum on time possible in a peak current mode controller. In valley current mode, useful information is derived when the LFET is ON, thus staying away from noisy UFET signals. Adaptive slope compensation on a valley current mode provides stable compensation across a wide range duty cycle. The adaptive slope compensation is adjustable and Intersil has employed voltage feed forward (VFF) in its modulator. The combination of these two features provides the ISL8117/A with the benefits of both a voltage mode and current mode modulator.

Delivers High Efficiency Performance

Efficiency not only helps power consumption, it also improves system reliability. More efficiency means less heat and hence reliable operation. The ISL8117/A has multiple features to boost efficiency across all loads. For example, the strong driver supports high current MOSFETs and boosts efficiency at higher loads. External bias saves internal LDO losses, hence boosting efficiency on the boards where a 5V rail is readily available. ISL8117 also has DEM mode with pulse skipping, which boosts efficiency at light load without introducing a variable frequency like PFM mode. ISL8117 runs on a very low Iq of 2.5mA which helps in lighter loads and prolongs battery life. The graph on the right side of the slide gives a clear idea of the impact that external bias and DEM mode makes in terms of efficiency. As you can see, at 1A load efficiency, the difference is 9%.

Simplifies Three Phases of Design

Here is an easy explanation on how the ISL8117/A makes a system designer’s life easy by making power supply design simple. There are three aspects of power supply design: component selection, circuit design and layout design. ISL8117/A makes design easy on all three fronts.

Component selection: First, you need to select the ISL8117/A. Once the ISL8117/A is selected, a designer may not need to select another controller for a different rail on the board or system because the ISL8117/A covers a wide range of input and output combinations. The ISL8117/A has a very low pin count and uses less external components. Its internal compensation and internal default design values further reduce the number of required external components.

Circuit design: Less pins and fewer components directly translate to a less complicated circuit. Internal compensation reduces the design effort even further.

Layout design: The ISL8117/A pin architecture has been designed in such a way that it can run on a bare minimum circuit for a basic buck converter. All additional function/feature pins have default values and can be sorted out without any additional components. All high power pins and signal pins are placed on opposite sides, therefore reducing any chance of interference. The ISL8117/A pins are organized to avoid layout errors by avoiding trace overlaps.

Beat Power Design with Simplicity: ISL8117

Here is a rough comparison between two solutions for a 42V to 12V power conversion. From the circuit and as listed here on this slide, it is clear that for the same power specification, the ISL8117 uses less pins, less external components and is less complicated. The default values of different pins in the ISL8117 helps the designers immensely in terms of circuit design effort if they don’t have any complicated spec requirements.

ISL8117: Best-in-Class High Voltage Controller

In the 60V category, Intersil’s ISL8117 offers multiple best-in-class features that matter most to industrial customers. Critical parameters like switching frequency, minimum on time, IC pin count, number of external components, easy layout design, and strong gate drivers all give tangible benefits in real-world applications.

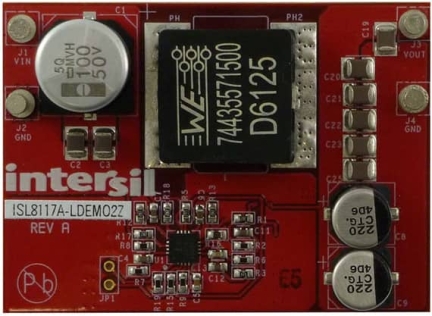

ISL8117: Evaluation and Reference Design Boards

To serve customers better, we have designed multiple evaluation and reference design demo boards for different markets—the larger evaluation boards to learn about product details and the smaller reference design demo boards to create practical and optimal designs. We have separated the evaluation boards and reference boards into two different categories—one for low current markets such as industrial and robotics and the other for high current markets such as telecom and power modules.

ISL8117A: Evaluation and Reference Design Boards

The ISL8117A also has evaluation boards for the two categories and a reference demo board for the low current market.

ISL8117EVAL1Z Reference Design for 20W Output

Let’s take a look at the ready-to-use reference designs. This is a basic design using the ISL8117 in the HTSSOP package. Input can be any voltage from 4.5V to 60V and output is set at 3.3V for 6A of load current. Please note that if the designer does not have any specific requirements on different functional pins, such as soft-start or rise time (RT), those extra components can be saved by using the default internal values. Also note that the EXTBIAS pin is grounded since it is not used. If we have an external power source of 5V or you can create a 5V supply, efficiency can be boosted further, as we saw in previous slides and in next couple of slides.

ISL8117DEMO3Z and ISL8117ADEMO1Z Reference Design for 20W Output

The ISL8117DEMO3Z and ISL8117ADEMO1Z are similar to the ISL8117DEMO1Z, except they use the QFN package and reduce the switching frequency to achieve even higher efficiency. The ISL8117ADEMO1Z also has external compensation. The input and output are easily connected to a circuit for testing purposes or as part of a prototype.

ISL8117DEMO2Z Reference Design for 240W Output

The ISL8117DEMO2Z is a 240W 12V design. It delivers 98% efficiency when the input voltage is 18V—the complete design is configured into a 40mm x 35mm board area.

ISL8117DEMO2Z Schematic

Here is the circuit for the 240W design. As you can see, we are using an external LDO in order to boost the efficiency. If you have an available 5V source, you can depopulate the LDO. The ISL8117 will automatically switch to internal LDO mode and take care of it. If your output is 5V, then you just need to connect your output to this pin and the ISL8117 will self bias itself from its own output.

Industrial Applications: Networking and Communications

Customers are showing an increasing amount of interest to move away from intermediate stages and utilize the higher input voltage bus. The 12V intermediate bus, though well established, has added complexity and distribution losses. A high voltage bus allows users to eliminate the extra conversion bus where ever necessary and improves system cost and efficiency. Here is an example of a microwave communication system where a traditional 12V bus can be eliminated to improve system cost and efficiency.

Industrial Applications: Medical Diagnostics

Here is another example of a high voltage application where intermediate rails are being used. The common input rail in industrial applications are 42V, 36V or 24V. These rails normally see a peak voltage which is 15% to 25% higher than the nominal voltage.

There are three different reasons this input voltage variation occurs:

- Poor power source,

- Fully charged battery voltage is higher than the nominal voltage,

- Voltage spike occurs when load is disconnected and the spike value depends on source quality and input capacitor.

In addition, these types of customers want an extra margin of safety. For a 24V battery system, an input requirement of 42V is very common.

This slide shows an example block diagram of an ultrasound machine, which uses an input rail of 24V or 36V along with a battery backup system. They typically have 20 to 25 power rails. Three to four rails are high power rails to drive DSPs, CPUs and FPGAs. In general, the input rail is first converted to 12V and or 5V rails. The ISL8117/A and other high voltage products are well suited for these applications. They use different power topologies such as buck, boost, LDO, display drivers, and simple voltage inverters among others.

ISL8117/A: Other Target Applications

Other applications that are ideal for the ISL8117/A 60V synchronous buck controller include high power LED panel/hoardings, power modules, after market infotainment, and 24V/36V battery power applications to name a few.

Intersil Investing in Industrial Power

The ISL8117/A is an innovative high voltage controller designed to address major concerns of industrial customers.

The ISL8117/A 60V controller simplifies industrial power supply designs by:

- Eliminating the intermediate step-down stage and allowing 48V to 1V conversions

- Providing internal default design settings

- Improving on efficiency (up to 98%) by using a low operating current and DEM/pulse skipping

Complete evaluation and reference design boards for the ISL8117/A are available to enable design replication and faster time-to-market.