Environmental Activities

Environmental Initiatives | Environmental Protection Goals | Climate Change Initiatives | Conserving Water | Waste Reduction Efforts | Chemical Substance Use | Eco-Product Initiatives | Eco-Communication Initiatives | Biodiversity Conservation Activities | Environmental Data and Third-Party Verification

Waste Management Initiatives

Waste Management Policy

Renesas strives to reduce, reuse or recycle as much waste as possible. Our waste management methodology is based on proper sorting and safety treatment. All of our production sites adhere to environmental action guidelines and local regulations.

Basic Concept and Target

90%

or more

Renesas Group is focusing on the 3Rs ("Reuse," "Reduce," and Recycle") to maintain the waste recycling rate at *90% or more globally. We diligently implement these "3Rs" during manufacturing and intend to reuse all the waste generated derived from our business activities as resources as a mid-term goal

*Recycling rate (%) = 100 - (Final disposal amount ÷ Total amount of waste & valuable emissions) x 100. Proper processing, such as thermal recycling and neutralization treatment, is also included.

The 3Rs Activity Overview

Reuse

Renesas uses plastic packaging materials (trays and magazines) for product shipments. We have a reusable infrastructure (collection-cleaning-inspection system) in place at our global production sites to ensure those materials are efficiently reused. Carrier tape, cardboard and wafer cases are also being reused for other applications.

Reduce and Recycle

During manufacturing and factory design processes, we are making efforts to minimize waste generation as much as possible and promote waste recycling by working together with companies in other sectors. For example, cement manufacturers are using sludge we generate from the effluent treatment as roadbed and cement materials. Metals are also reused for material steel manufacturing, and paper as raw materials are converted to recycled paper. We are also recycling scrap wafers generated during the production process and final products that are considered defective.

| Waste Materials | Examples of Recycling |

|---|---|

| Sludge | Roadbed materials, raw materials for cement, recycled sand, raw materials for metal refining |

| Waste Oil | Incinerator combustion aid, recycled oil, raw materials for cement |

| Waste Acid | Recycled sulfuric acid, wastewater treatment, fuel conversion, raw materials for cement, raw materials for metals |

| Waste Alkali | Fuel conversion, raw materials for cement, raw materials for metals |

| Waste Plastics* | Incinerator combustion aid, solid fuel, raw materials for plastics |

| Metal Scraps* | Raw materials for metals |

| Glass and Porcelain Scraps | Raw materials for glass, raw materials for cement, tiles, lightweight aggregates |

| Product Waste* | Raw materials for silicone |

| Precious Metals* | Raw materials for precious metals |

| Paper | Raw materials for recycled paper |

| Wood Chips | Raw materials for paper, fertilizers, fuel |

| Styrofoam | Paint and mortar aggregates |

* Including scrap wafers generated during the production process and products that are considered defective.

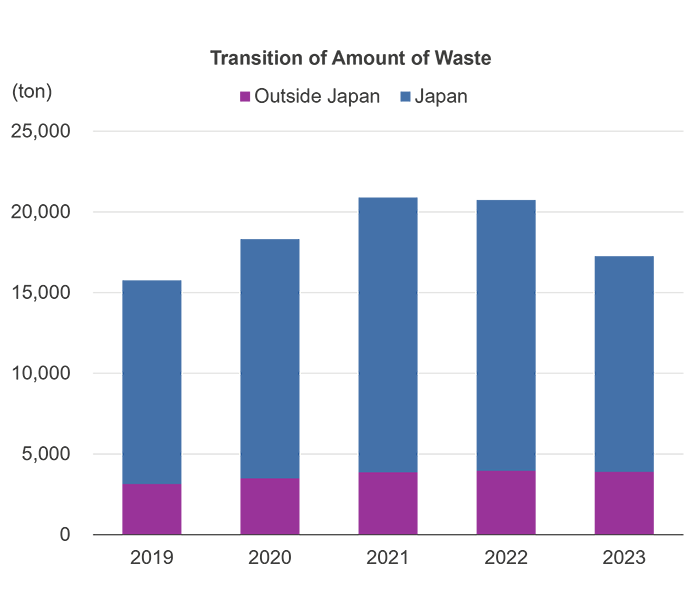

The 3Rs Performance

The amount of waste generated in FY2023, In the fiscal year 2023, the amount of waste disposal decreased by 17% compared to the previous year. This reduction was attributed to the planned implementation of activities aimed at reducing industrial waste and waste plastics, in addition to the softening of the semiconductor market and the elimination of temporary increases in waste disposal resulting from the closure of production bases in Japan that occurred in the previous year.

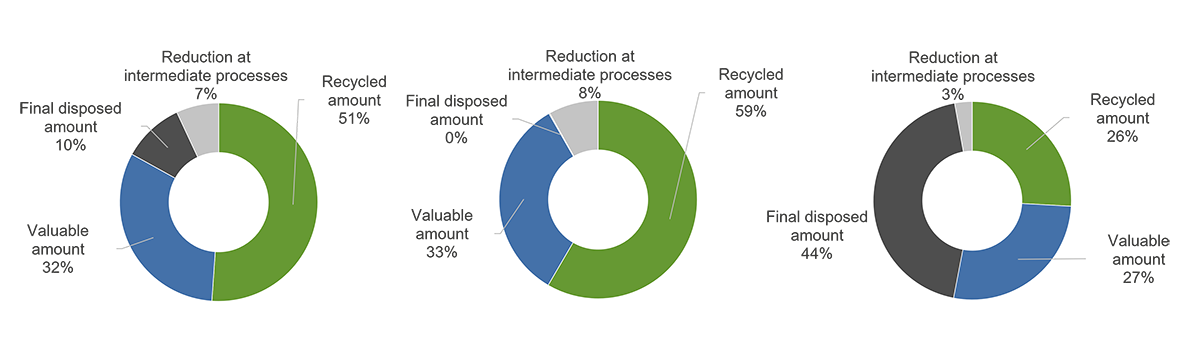

More than 99% of domestic waste in 2023, which accounts for about 78% of all waste, is reused, recycled, or properly intermediately treated. The final landfill disposal rate (final disposal amount) was 0.15%. Compared to Japan, the proportion of landfill disposal (final disposal volume) of waste outside of Japan was higher at 44%.

The waste recycling rate at our global bases was 90% due to a decrease in the waste ratio in Japan, which has a high recycling rate, and we are maintaining our benchmark of 90%.

Waste Reduction Initiatives

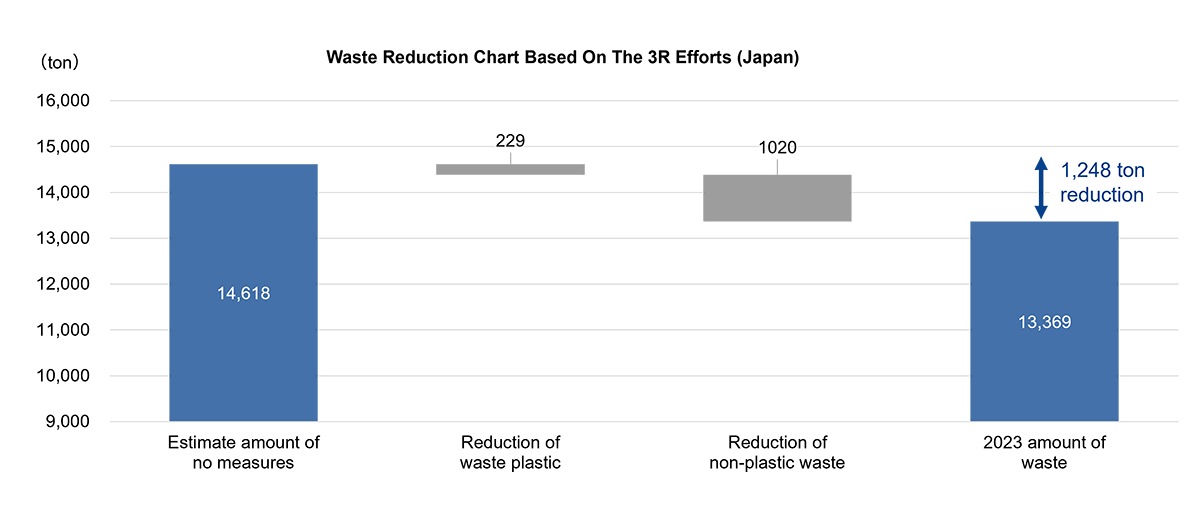

In 2023, Renesas Group achieved a waste reduction of 1,248 tons (including 229 tons of waste plastic reduction) in Japan.

In 2023, Renesas continues to implement following initiatives.

FY2023 Major Initiatives (including ongoing activities)

[Reduction of plastic waste (Response to the new Plastic Resource Circulation Act in Japan)]

- Reusing or recycling of plastic packaging materials (tray), plastic cases and Styrofoam.

- Reducing plastic waste by increasing the size of BGA package

- Clean and recycle resin containers after using CMP slurry or use them as recycled materials.

- Instead of purchasing garbage bags needed for cleaning activities around the factory, reusing the bags produced during the manufacturing process.

[Overall waste reduction activities]

- Valuable waste liquid and oil, and activities to reduce the amount of wastewater treatment sludge.

- Promotion of waste reduction activities among teams participating from all Japanese sites

Environmental Pollution and Laws and Regulations

Renesas Group is committed to proper management and disposal in accordance with relevant waste laws and regulations.

Initiatives for the "Plastic Resource Recycling Promotion Law (Japan)"

99.9%

or more

In April 2022, the "Plastic Resource Recycling Promotion Law" took effect in Japan. Renesas Electronics Corporation (REL) and Renesas Semiconductor Manufacturing (RSMC) are corresponded to "large amount of plastic waste producers" that discharge industrial waste plastics in excess of 250 tons each year.

Renesas Group (in Japan) proactively work on "reducing total waste, reducing waste plastic, and maintaining a waste plastic recycling rate of 99.9% or more" by Promoting of value conversion by separating waste plastic and in addition reducing weight, reuse, recycle.

Amount of waste plastic (ton, excluding valuable, Japan)

| April 2021~March 2022 | April 2022~March 2023 | April 2023~March 2024 | |

|---|---|---|---|

| Renesas Electronics Corporation | 482 | 448 | 411 |

| Renesas Semiconductor Manufacturing | 492 | 415 | 503 |

| Total | 974 | 863 | 914 |

Preventing Soil Pollution

When harmful chemicals are passed into and accumulated in the soil, there are concerns about their negative impact on human health, crops, and ecosystems. In an effort to prevent harmful chemical substances from being passed into the soil, we systematically implement measures to reduce the risk of chemical leakage and to prevent permeation into the soil in the unlikely event of leaks.

Furthermore, in our annual environmental audits, we confirm the management status of chemical substances, including the storage locations of chemical substances and the management status of facilities used, and the status of response procedures in the event of leaks, and actively propose measures to further reduce risks.

Facilities that have already taken measures

- Replacement of underground kerosene tanks (Yonezawa Factory)

- Replacement of positive film development waste liquid treatment tank (Saijo Factory)

Contributing to SDGs

Renesas’ efforts in Waste Reduction contributes to these Sustainable Development Goals targets:

3.9 By 2030, substantially reduce the number of deaths and illnesses from hazardous chemicals and air, water and soil pollution and contamination.

11.6 By 2030, reduce the adverse per capita environmental impact of cities, including by paying special attention to air quality and municipal and other waste management

12.4 By 2020, achieve the environmentally- sound management of chemicals and all wastes throughout their life cycle, in accordance with agreed international frameworks, and significantly reduce their release to air, water and soil in order to minimize their adverse impacts on human health and the environment

12.5 By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse

15.3 By 2030, combat desertification, restore degraded land and soil, including land affected by desertification, drought and floods, and strive to achieve a land degradation-neutral world

15.4 By 2030, ensure the conservation of mountain ecosystems, including their biodiversity, in order to enhance their capacity to provide benefits that are essential for sustainable development

Environmental Activities

Environmental Initiatives | Environmental Protection Goals | Climate Change Initiatives | Conserving Water | Waste Reduction Efforts | Chemical Substance Use | Eco-Product Initiatives | Eco-Communication Initiatives | Biodiversity Conservation Activities | Environmental Data and Third-Party Verification