-

-

-

Design Resources

- Design & Development

- Featured Design Tools

- Partners

- Content & Training

-

Support

-

Support Forums

Get help from our expert Renesas technical staff and community.

- Technical Support

- Training & Events

- Quality & Packaging

-

Support Forums

-

Sample & Buy

-

Buy Direct from Renesas

Customers can now choose the convenience of buying direct from Renesas.

- Ordering Resources

-

Buy Direct from Renesas

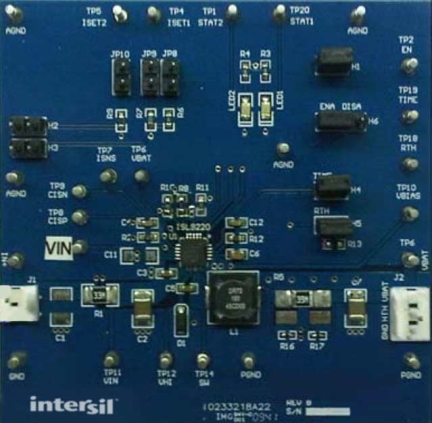

ISL9220IRTZEVAL1Z

circleObsoleteSwitching Charger Evaluation Board for 1-Cell Li-Ion and Li-Polymer Batteries

Overview

Description

The ISL9220IRTZEVAL1Z evaluation board is used to evaluate the ISL9220 battery charger for 1-cell Li-ion and Li-polymer batteries.

The device features synchronous PWM technology, maximizing power efficiency, thus minimizing charge time and heat. The 1.2MHz switching frequency allows use of small external inductors and capacitors. A simple charge current programming method is provided. External resistors program the fast charge and end-of-charge currents. The two status outputs can be used to drive LEDs, or can be connected to a host processor. A programmable charge timer provides the ability to detect defective batteries and provides a secondary method of detecting charge termination. A thermistor interface is provided for battery presence detection and for temperature qualified charging conditions. Additional features include preconditioning of an over-discharged battery, automatic recharge and a thermally enhanced QFN package.

Features

- Operating input voltage range: 4.5V to 14V

- Up to 2A charge current

- Two status outputs

- 1.2MHz switching frequency

- Connector, test point and jumper

Applications

Applications

- PDAs and smartphones

- MP3 and portable media players

- Handheld GPS devices

- Digital still cameras

- Industrial handheld scanners

Related Products

Documentation

|

|

|

|

|---|---|---|

| Type | Title | Date |

| Manual - Development Tools | PDF 455 KB | |

| Datasheet | PDF 810 KB | |

2 items

|

||

Design & Development

Product Options

Buy / Sample |

|

|---|---|

| Part Number | |

ISL9220IRTZEVAL1Z circleObsolete |

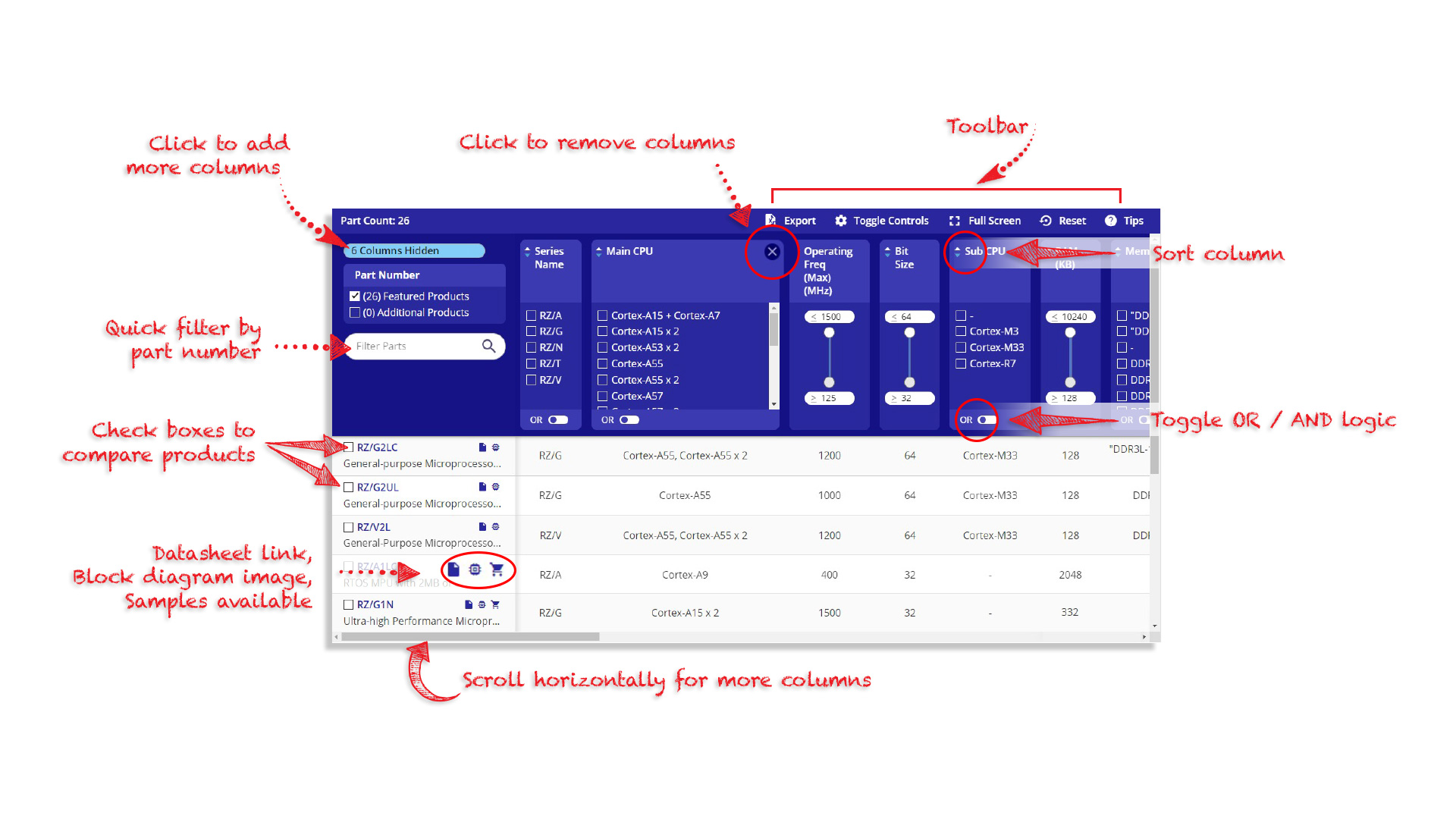

Tips for Using This Parametric Table:

- Hide Filters button in header: Collapse or expands filters

- Column sort buttons in header: Sort Column alphabetically / numerically descending or ascending

- Reset button in header: Reset all filters to the page default

- Full Screen button in header: Expand the table to full screen view (user must close out of full screen before they can interact with rest of page)

- Export button in header: Export the filtered results of the table to an Excel document

- Filter parts search bar in header: Type to filter table results by part number

- Hide column button in column headers: Select to hide columns in table

- AND / OR toggle switches in header: Toggles the logic of this particular filter to be “AND” or “OR” logic for filtering results

- Multiselect checkboxes at beginning of each row in table: Select these checkboxes to compare products against each other

- Document icon next to product name in row: View the featured document for this product

- Chip icon next to the right of the document icon in row: View the block diagram for this product

- Cart icon to the right of the chip icon: Indicates that samples are available for this product