Automotive Single-Cell Lithium Iron Phosphate Battery Charger Evaluation Board

概览

简介

The ISL78693EVAL1Z evaluation board is used to evaluate the performance of the ISL78693 integrated single-cell automotive LiFePO4 battery charger. The onboard 8-bit DIP switch facilitates battery charge current programming, setting EN input, temperature monitoring status, etc. The four jumpers can set up the input source selection, USB mode selection, and can be used to make other necessary connections.

特性

- Complete charger for single-cell Li-ion batteries

- Integrated pass element and current sensor

- No external blocking diode required

- 1% voltage accuracy

- Programmable current limit up to 0.5A

- NTC thermistor interface for battery temperature monitor, 8-bit DIP switch for conveniently setting up charging current, battery thermal status, EN input, etc.

- Different jumpers for input source selection, USB mode selection, and the convenience of current measurement

- Test points provided for STATUS, FAULT, TIME, EN, V2P8, and TEMP functional pins to allow for monitoring the device pins

- Board size 3.5" x 2.5" for the convenience of evaluation

- Eight thermal vias in the thermal pad

- RoHS compliant

应用

应用

- Automotive systems

- eCall systems

- Backup battery systems

设计和开发

软件与工具

视频和培训

This webinar discusses the ISL78693 AEC-Q100 automotive-grade, fully integrated, 3.6V single-cell battery charger, intended for lithium iron phosphate (LiFePO₄) batteries.

Transcript

ISL78693 – Automotive LiFePO₄ Single-Cell Battery Charger

This is a presentation for the ISL78693, an automotive-grade single-cell Lithium Iron Phosphate battery charger.

ISL78693 – 3.6V Single-cell Battery Charger

The ISL78693 is an AEC-Q100 automotive grade, fully integrated, 3.6V single-cell battery charger, intended for Lithium Iron Phosphate batteries.

It offers the popular constant current, constant voltage charging profile. Some of its key features are:

- A preconditioning trickle charge for fully depleted batteries

- Charge current thermal foldback, to prevent the IC from overheating

- A thermistor input that can monitor the battery temperature and disable charging when the battery temperature is too hot or cold

- And, extremely low reverse battery leakage of 700nA typical and 3µA max

ISL78693 is rated for ambient temperatures from -40 °C to 85 °C and is offered in a very small 3mm x 3mm 10-lead DFN package.

In the following slides, I will describe in more detail the functionality provided by the ISL78693, the application it will address, and the benefits it offers these applications.

Intersil Automotive-Grade Single-Cell Battery Chargers

Intersil now offers two automotive-grade single-cell battery chargers.

The previously released ISL78692 is optimal for Li-ion and Li-Polymer batteries. These batteries offer very high energy density and have a nominal cell voltage of 3.6V. They should be charged at around 4.1V.

ISL78693 is a pin-to-pin compatible derivative of the ISL78692 where the charging profile was optimized for Lithium Iron Phosphate batteries. Even though LFP batteries offer lower energy density, they are often selected for automotive applications because they are more robust, with internal chemistry that is more stable. LFP batteries are much less likely to fail when misused or mishandled and importantly, much less likely to catch fire. LFP batteries have a lower nominal cell voltage of 3.2V and are recommended to be charged at 3.5V to 3.65V.

In addition to the changes in the charging profile, the ISL78693 also sports a reduced UVLO threshold, allowing it to operate from a 4V supply.

Provides a Complete Charging Solution

Here is an example of the typical CC/CV charging profile which the ISL78693 uses. In the graph, the blue curve illustrates the battery potential and the red curve illustrates the charging current. Most of the charging cycle occurs at a fixed or constant current level, I-charge. This is illustrated by the flat portion in the middle of the red curve. If the battery voltage is below 2.6V, the charger operates in precharge mode to prevent damage to the battery. Here, it will charge the battery with 10% of the programmed charging current until the battery voltage reaches 2.6V. At 2.6V, the ISL78693 will switch to the full charge current and continue charging until the battery reaches 3.65V. At this time, the charger will switch to constant voltage mode and will maintain the battery voltage at 3.65V until the charge cycle times out. If the battery voltage drops below 3.25V, the ISL78693 will automatically recharge the battery.

Features and Benefits

Now I'd like to describe the benefits of some of the ISL78693's key features.

The ISL78693 offers a programmable charging current, up to 1A, to provide customers flexibility in designing the system. Customers commonly use approximately 500mA to charge batteries with capacity around 1Amp-hour. By offering up to 1A, the ISL78693 provides support for larger capacity batteries or faster charging times.

ISL78693 is designed to charge the battery to 3.65V. Once a charging cycle has completed, the ISL78693 will disable itself and monitor the voltage of the battery. When the battery potential falls to 3.25V, it will automatically recharge back to 3.65V. The 3.65V charging voltage is ideal for many LFP batteries and, in particular, is preferred over 4.1V/4.2V when charging Lithium Iron Phosphate batteries.

Features and Benefits

Reverse battery leakage is the current that the battery charger will pull from the battery when the charger is not enabled or not powered. All charger ICs will draw some current unless an ideal external blocking diode is added. Reverse battery leakage is specified on the ISL78693 to be 700nA typical and 3µA max; this is the lowest guaranteed reverse battery leakage for any automotive-grade charger. This is important because the higher the reverse battery leakage, the faster a charged battery will be discharged while the vehicle is off, so the ISL78693 will allow the backup battery to remain charged the longest.

Thermal foldback of charging current automatically reduces the charging current when the die temperature exceeds 100 °C. The figure illustrates the charging current at three battery voltages. Notice that independent of battery voltage, the charging current is reduced at the same junction temperature. Thermal foldback effectively regulates the junction temperature to be very near 100 °C. This prevents the IC from overheating and allows the charger to maintain operation. This improves the reliability of the system and can relieve the system designer from performing extensive thermal modeling of the PCB.

Market Opportunity

The ISL78693 could be used in any system that requires a Lithium Iron Phosphate battery, but currently, the primary application is charging a small backup battery used in emergency telematics and communications systems. Emergency telematics systems are used to communicate with authorities after an accident or other unexpected event. Examples of this type of system are OnStar in the US, eCall in Europe, GLONASS in Russia, SVT in Brazil, and D-Call in Japan. In Europe and Russia, regulations are mandating these systems be installed on all new vehicles. This mandate is driving substantial growth in this application.

ISL78693 Addresses Key Customer Challenges

For customers designing emergency telematics systems, the ISL78693 offers benefits in three areas:

First, it offers the lowest reverse battery leakage of any automotive qualified charger. As we saw earlier, reverse battery leakage drains the backup battery while the vehicle's main power is off. Our customers want to minimize this leakage so that they can guarantee their backup battery will remain sufficiently charged, even if the vehicle is parked for extended periods of time. ISL78693 offers industry leading performance on this parameter.

Second, Lithium Iron Phosphate batteries are preferred for automotive applications due to their high reliability and their resistance to catching fire. Lithium Iron Phosphate batteries should be charged to 3.6V and the higher these batteries are overcharged, the more degradation to the expected operating lifetime occurs. By virtue of its 3.65V charging voltage, ISL78693 offers an increase in the operating lifetime when compared to chargers that provide 4.1V or 4.2V. Also, the ISL78693 offers a thermistor input which can monitor the temperature of the battery and ensure that charging only takes place when the battery is in the proper operating temperature range. This prevents damage to the battery and extends the system's reliability.

And finally, the ISL78693 offers features that help to miniaturize the final solution. It is fully integrated and requires only a few external passive components. Second, it is offered in a tiny 3mm x 3mm package. And, it offers thermal foldback of the charging current which will regulate the die temperature to prevent overheating. This eliminates the need for external heat sinking and allows the ISL78693 to be placed on very small PCBs where there is limited room to dissipate heat.

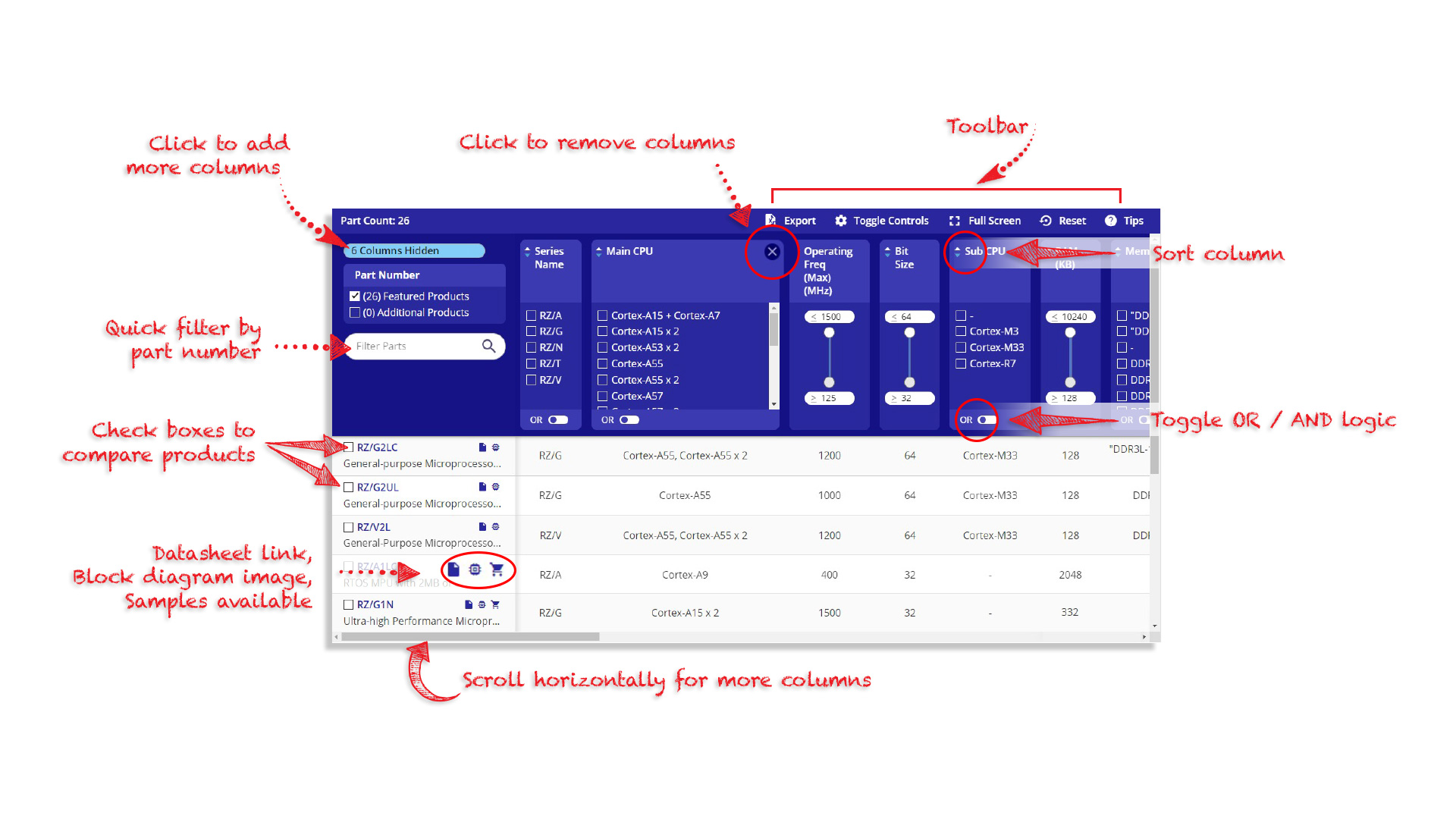

ISL78693EVAL1Z Evaluation Board

Finally, a full-featured evaluation board for the ISL78693 is available. Most of the performance charts in the datasheet were measured using this board. The schematics and layouts, as well as the user's guide are available on our website on the ISL78693 product information page.