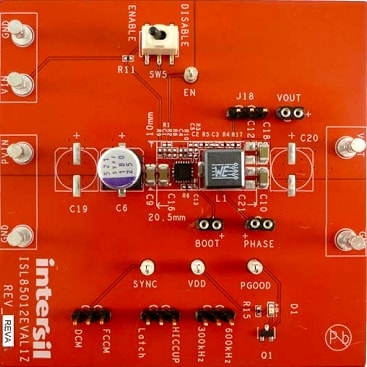

12A, 3.8V to 18V Input, Synchronous Buck Regulator Evaluation Board

Overview

Description

The ISL85012EVAL1Z board is used to evaluate the performance of the ISL85012 high-efficiency synchronous buck regulator. The ISL85012 features integrated power switches that are capable of delivering 12A of continuous current within a 3.5mm x 3.5mm package.

The ISL85012 is a highly efficient, monolithic, synchronous buck regulator that can deliver 12A of continuous output current from a 3.8V to 18V input supply. The device uses current mode control architecture with a fast transient response and excellent loop stability.

The ISL850xx sync buck regulators support input voltages of 3.8V to 18V and a wide output current range, offering designers a complete portfolio of devices with high efficiency and reliable performance.

Features

- Small, compact design

- Switch selectable EN (enabled/disabled)

- Jumper selectable mode (auto-DCM/forced-PWM)

- Jumper selectable OCP mode (hiccup/latch-off)

- Jumper selectable default frequency (600kHz/300kHz)

- Connectors and test points for easy probing

Applications

Applications

- Servers and cloud infrastructure POLs

- IPCs, factory automation, PLCs

- Telecom and networking systems

- Storage systems

- Test measurement

Documentation

|

|

|

|

|---|---|---|

| Type | Title | Date |

| Manual - Development Tools | PDF 1.14 MB | |

| Datasheet | PDF 1013 KB 日本語 | |

2 items

|

||

Design & Development

Software & Tools

Videos & Training

Find out how Intersil's high efficient, compact 12V synchronous buck regulator family can meet your power requirements for 12V rails in industrial and infrastructure applications.

Transcript

12V Synchronous Buck Regulator Family

Today I would like to introduce one of the most efficient and compact synchronous buck regulator families in the marketplace today.

There are many 12V rails in industrial applications today that need a buck converter to step the voltage down to a lower voltage and deliver up to 14A. Some of these applications often require a very efficient and compact solution. The highly integrated buck regulators listed here allow the users to meet all these requirements.

The ISL85009, ISL85012 and ISL85014 are pin compatible, very efficient and are able to deliver up to 14A. In applications that need less than 5A, Renesas offers ISL85003 and ISL85005 that are pin compatible. The ISL85009, ISL85012 and ISL85014 can operate from 3.8V to 18V input voltage, and the output voltage can be set as low as 0.6V. This family is highly integrated. The high-side and low-side FETs, with a bootstrap diode and compensation circuits are all integrated which helps to reduce the size, cost and bill of material.

This family is also highly reliable. It has high-side and low-side overcurrent protection, input and output overvoltage protection, over-temperature protection and negative current protection all integrated in the IC. This family also provides full feature sets and design flexibility to customers.

For instance, the selectable OCP scheme feature gives flexibility to the power supply designer to choose between hiccup and latch-off OCP mode, depending on their application requirements. Finally, the ISL85009, ISL85012 and ISL85014 are pin compatible, highly efficient and capable of delivering up to 14A in a very small 3.5mm x 3.5mm TQFN package.

As you see in the efficiency curve here, the ISL85009 provides one of the most efficient solution in the marketplace today. To support our customers with this family, we have developed several evaluation and demo boards.

Supporting tools such as iSim model, PowerCompass, schematic and Gerber files are all available online for this family on our website.