Innovative Safety Analysis Tool

The GUI CAR (Customisable Analysis Report) Tool, an innovative safety analysis tool that will enhance customers’ ability to quickly integrate Renesas products into their safety-critical automotive systems while increasing user confidence in system compliance to the latest safety standard. The powerful new FMEDA (failure mode effects and diagnostics analysis) tool is optimized for the ISO 26262 standard, which addresses safety of electrical and/or electronic systems within road vehicles, and is the target for compliance of this revolutionary product.

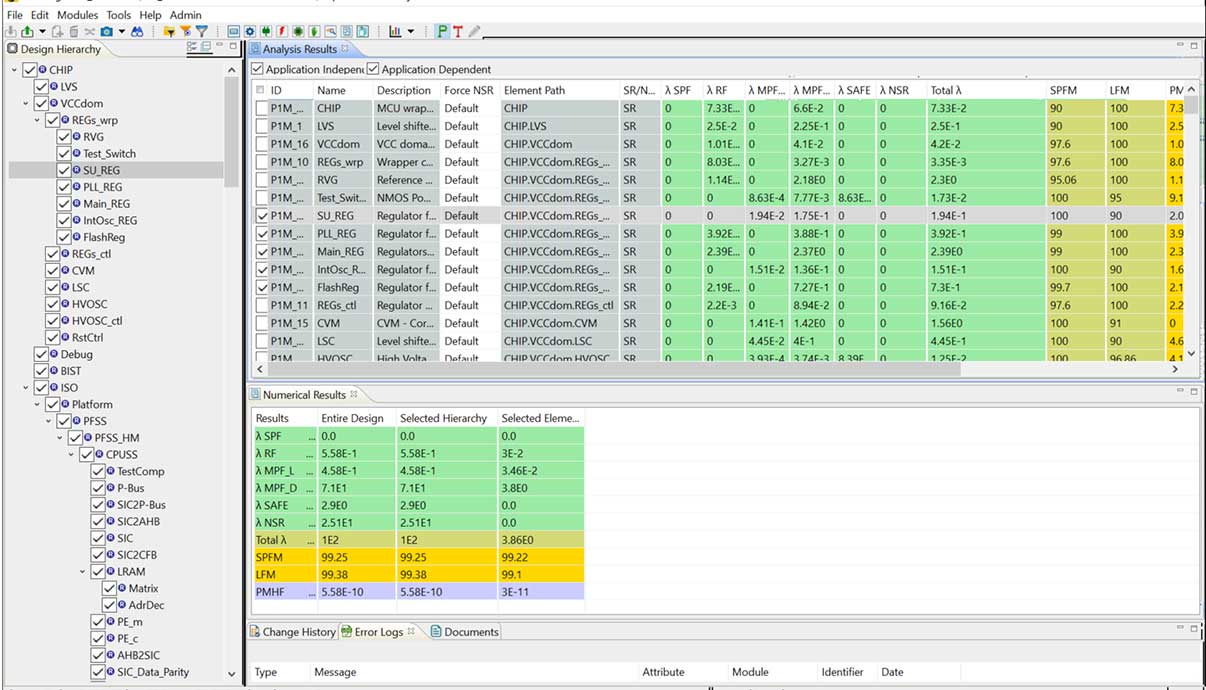

The CAR Tool unifies key aspects of the safety analysis by offering a multi-layered view of the safety-related component, complete with customizable analysis parameters and all of the results required by ISO 26262, such as single point fault metric (SPFM) and latent fault metric (LFM). This innovative tool also provides the user with estimations for both probabilistic metric for random hardware failures (PMHF) and its alternate method for the evaluation of each cause of safety goal violation. These results can be displayed from the entire component down to each single element via different hierarchical levels, accurately splitting its FIT in the appropriate fault class (single-point, residual, latent, etc.) This also makes it easy and effective to browse complex system-on-chip (SoC)/microcontroller (MCU) safety analyses. Please contact your local sales or support staff for more information.

Key Features

- Effective Graphical User Interface (GUI) for clear visibility and ease of customization

- Library import for Renesas components

- Possibility to create and share libraries between parties or from other suppliers

- Automatic calculation of ISO26262 HW architectural metrics

- Automatic calculation of PMHF and alternate method

- Handling of different Safety Goals

- Handling of different use cases

- Configuration of a golden library with a high degree of customization for different application profiles

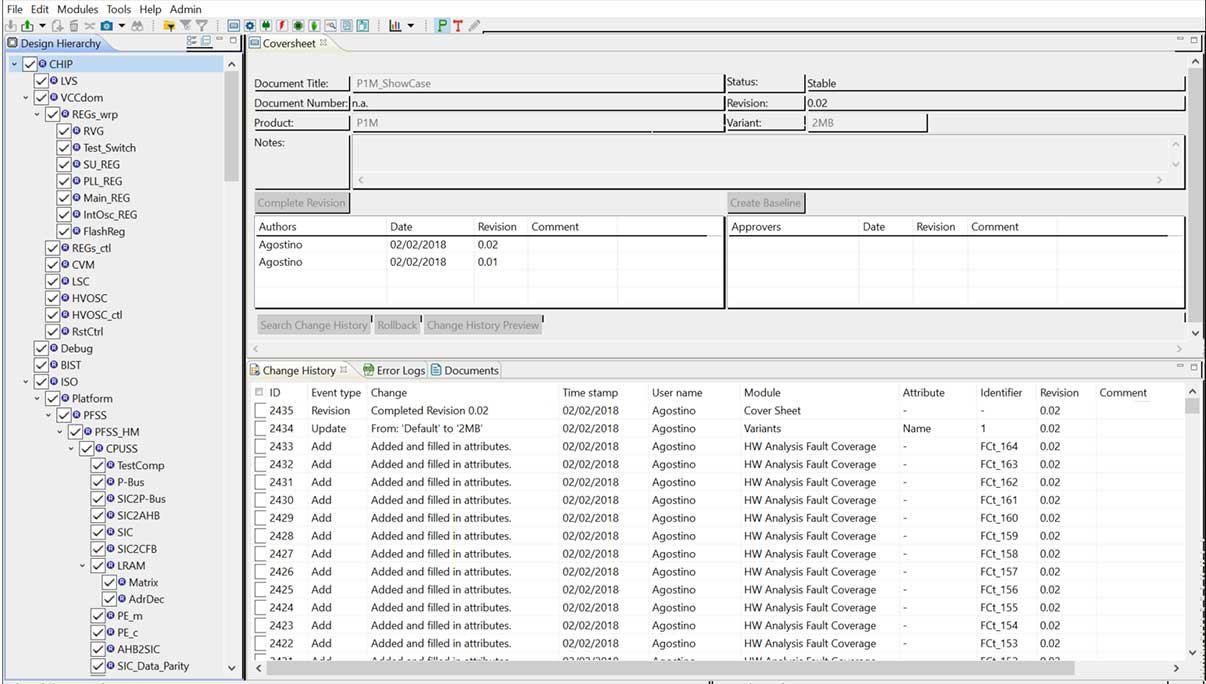

- Accurate revision control and change history support

- Error logging

- Embedded documents and references

- Possibility to customize many safety related parameters including:

- Fault characterization

- Fault impact

- FIT characterization and allocation

- Failure modes

- Safety-related status

- Safety mechanisms

- Fault coverage

Analysis Results

Car Tool Showcase