Do you know the Renesas’ Lab on the Cloud? It is a remote environment where users can access and test a board/kit online. Boards are configured in a remote lab connected to the cloud. Before users receive a physical board or start a design, they can quickly access to Renesas solutions virtually via this Renesas’ Lab on Cloud.

I would like to introduce the RX23E-A evaluation board RSSK, which is now connected to the Lab on the Cloud. The RX23E-A is a MCU that incorporates a delta-sigma ADC with low noise and drift. The Lab on the Cloud allows the evaluation of the noise performance of the delta-sigma ADC that is built in the RX23E-A.

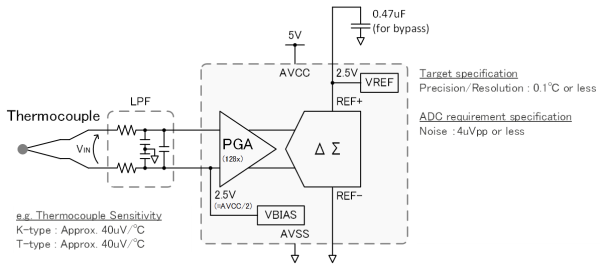

The noise performance is one of the important specifications for sensor measurement. RX23E-A is required to have low noise, particularly in the targeted fields of temperature and strain measurement. For example, a thermocouple, which is a typical temperature sensor, has a sensitivity of around 40uV/℃ for K- or T-type thermocouple that is commonly used. On the other hand, for the temperature measurement in industrial applications, a resolution is 0.1 ℃ or less is required. It means that to build a measurement system with a resolution of 0.1 ℃ or less using a K- or T-type thermocouple, the noise of the ADC should be suppressed to 4uVpp or less.

Then, I will try to confirm if the RX23E-A noise performance can support the thermocouple measurement by using the Lab on the Cloud as an example.

Step(1)

Set the Input Voltage, Data Rate (OSR), and PGA.

The Input Voltage is a voltage as the operating point, i.e. the input common voltage.

In this case, set it to 2500mV, which is half of the power supply voltage of 5V.

Set the Data Rate to 488SPS (OSR=1024). In normal applications, a temperature measurement cycle of 100SPS should be sufficient. However, in the case of the thermocouple measurement, it is common practice to switch between the thermocouple and the reference junction compensation (RJC) of the PT100. Therefore, the Data Rate is required to increase accordingly for the switching measurement, so the Data Rate is set to 488SPS in this case.

Set the PGA to x128 so that the input referred noise is the smallest.

Note that OSR is an abbreviation for Over Sampling Rate.

This concludes the settings of measurement conditions.

Step(2)

Click “RUN” to start A/D conversion. It takes about 1 minute for A/D conversion to begin due to the loading of the initial settings.

Step(3)

The A/D conversion result is displayed. After receiving the required amount of data, click “STOP”.

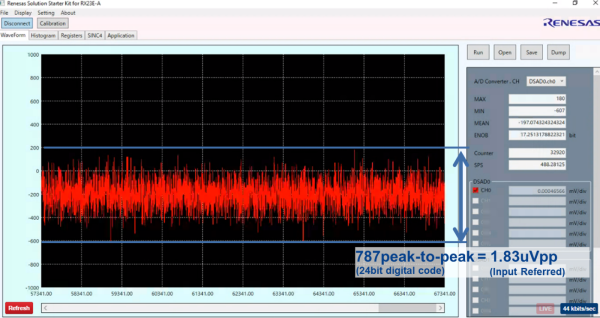

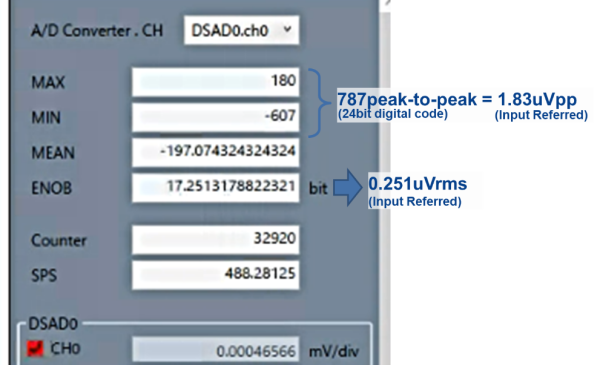

First, check the Waveform. It is the waveform for 10 seconds in this case. On the right side of the graph, you can see MAX, MIN, MEAN, ENOB=log2 (Full-Scale/RMS_noise), and the scale of the vertical axis of the graph (mV/div).

The measurement result is 787peak-to-peak by 24bit digital code. This is an input referred noise of 1.83uVpp, which is below the target specification of 4uVpp. In addition, the RMS noise is 0.251uVrms calculated backward from the ENOB.

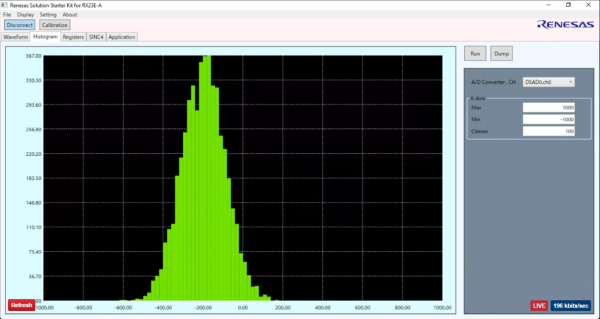

You can also check the result of histograms. It has a bell-shaped distribution which shows that there is no problem.

Step(4)

If needed, the scale of the axis can be changed.

This is the end of evaluation with Lab on the Cloud using the RX23E-A RSSK. Though users can evaluate only the noise performance of delta-sigma ADC with the Lab on the Cloud, an actual RSSK allows evaluation of the drift and connecting to various sensors. We recommend you to use the Lab on the Cloud for before purchasing the RX23E-A RSSK.

If you are interested, please try it on https://www.renesas.com/document/lab-cloud-high-precision-analog-measurement