Want to enter the inverter market for xEVs!

Want to shorten the development period of inverters for xEVs!

Want to cut down on development costs!

Want to improve the fuel efficiency of my eco-cars by controlling highly efficient motors!

I am writing this article for those who have the above requests.

Nice to meet you. My name is Minesawa from Renesas.

Renesas provides an Inverter Reference Solution for xEVs.

The xEV Inverter Reference Solution consists of the inverter hardware and software to control motors for xEVs. I'm in hardware development.

First of all, I would like to introduce an outline of the Inverter Reference Solution.

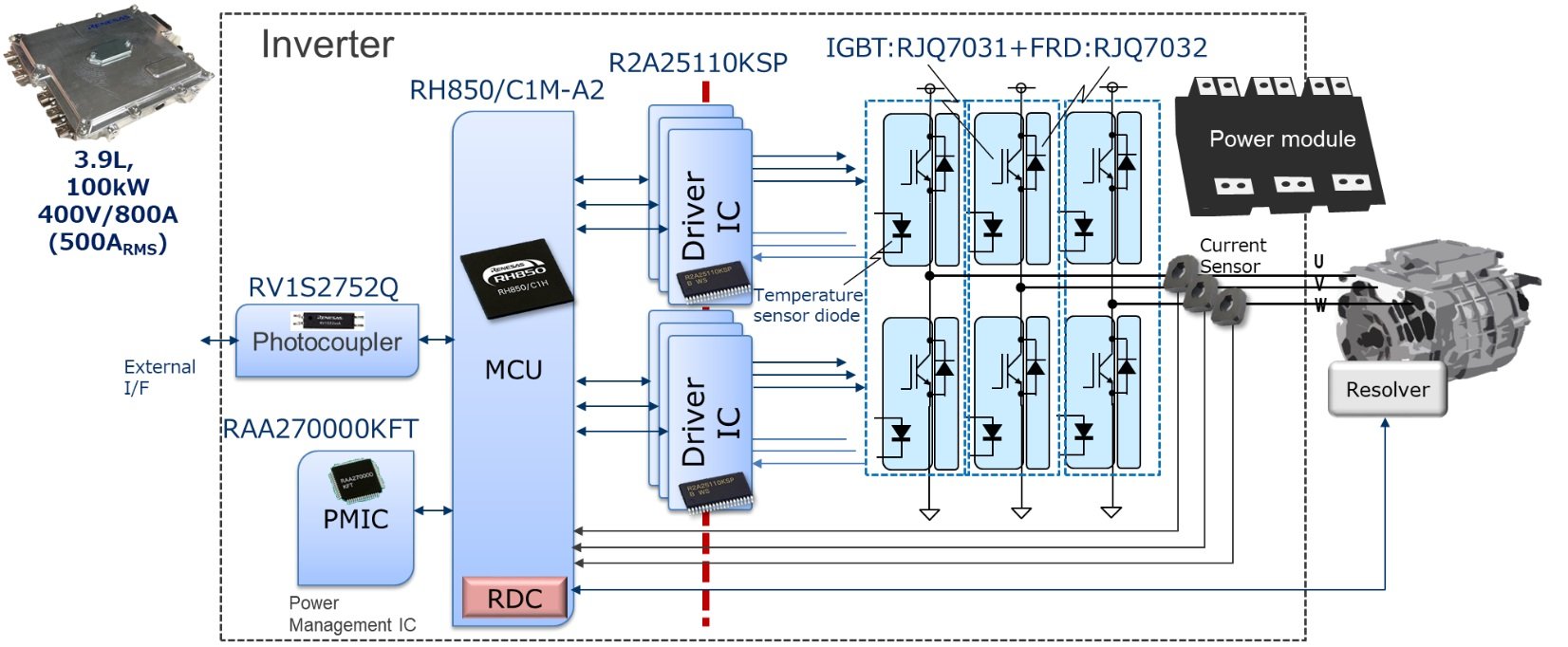

The solution achieves 100kW of output power, which is the volume zone of xEVs, in a compact size of 3.9L in volume. Renesas' microcontroller, PMIC, gate drive IC, IGBT/FRD bare die, and photocoupler, which are the main semiconductors of the inverter, are all integrated into the inverter.

We are able to provide services in the three areas of semiconductor + hardware system design + software system design. Total solution support is available.

The Inverter Reference Solution can be used to meet the following requirements.

Want to enter the inverter field for xEVs!

The deliverable material of this solution consists of the following:

- 100kW-class inverter body

- Hardware design information: schematic data, bill of materials, PCB data, mechanical component data, evaluation results

- Software design information: motor control software source code and evaluation results

- Tool for obtaining motor parameters and generating torque maps

You can get hardware and software design information for xEV inverters from scratch, and we provide strong support for new entrants into the xEV inverter market.

Want to shorten the development period of inverters for xEVs!, Want to cut down on development costs!

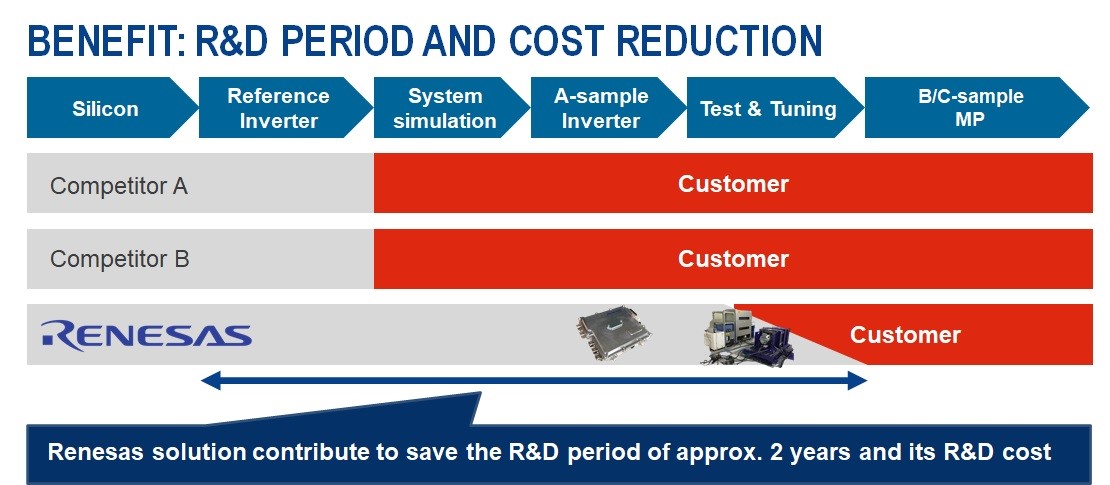

By using the solution, we will contribute to reducing the development period of about two years and its cost by replacing the "System Simulation" and "A-sample Prototyping" that our customers used to perform.

In addition, we have a "Motor Bench Dyno" and "Actual Vehicle Evaluation Environment" as our evaluation environment, and each function is evaluated with the Motor Bench and an actual vehicle. This not only reduces the amount of time and effort required by the customer to evaluate the Motor Bench but also allows the inverter to be used as a sample for the first time in an actual vehicle.

Want to improve the fuel efficiency of my eco-cars by controlling highly efficient motors!

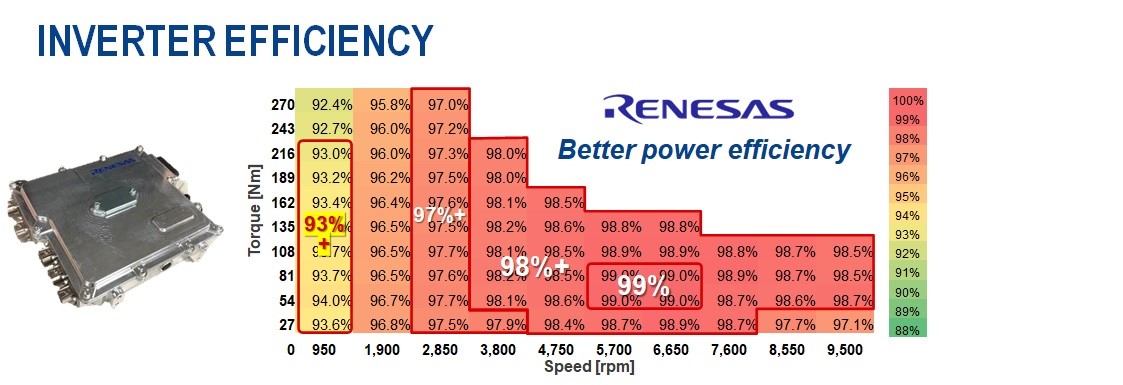

High efficiency is achieved by using semiconductors specialized for xEVs.

The xEV Inverter Reference Solution is available.

Want to enter the inverter market for xEVs!

Want to shorten the development period of inverters for xEVs! Want to cut down on development costs!

Want to improve the fuel efficiency of my eco-cars by controlling highly efficient motors!

We can be of help to those who have such requests.

If you are interested in this service, please contact our sales team.