Traditionally, there’re numerous analog sensors and actuators in the manufacturing plant with maintenance difficulties and bad transmission quality due to multiple rotating devices such as motors, existing complex wiring, and so on.

In order to establish industrial 4.0 from industrial network to endpoint field bus applications, particular sensors and actuators with IO-Link offer the following benefits:

- System diagnosis from single IO-Link master to multiple IO-Link slaves

- From analog to digital sensor signal node with better immunity capability

- Bi-directional communication complies with IEC 61131-9 as International Standard

- Robust point-to-point communication with maximum 20m without attenuation

- IODD (IO Device Description) file enables users to easily monitor and control in real-time operation.

In our previous blog, we introduced the IO-Link Temperature sensor solution, and this time, we are going to introduce the RA2E1 IO-Link Pressure sensor solution containing TMG IO-Link evaluation stack library.

Customers can easily take the library without applying the license for purpose of evaluation and implementation into the demonstration.

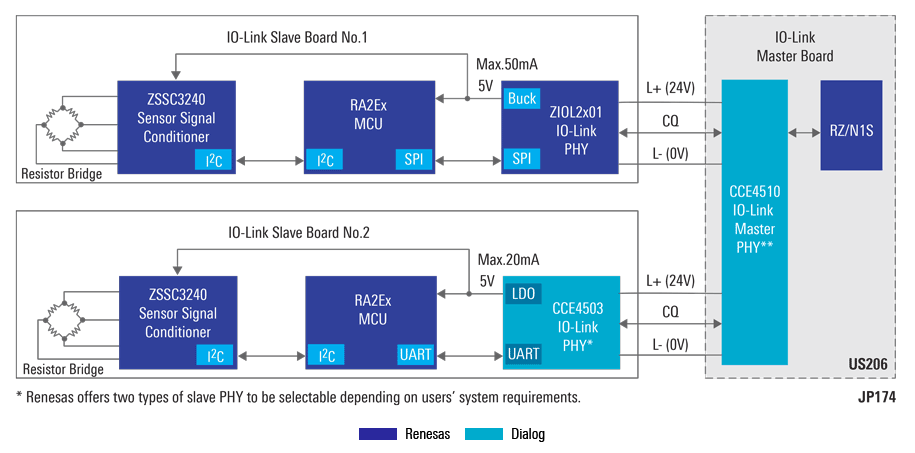

- System configuration features

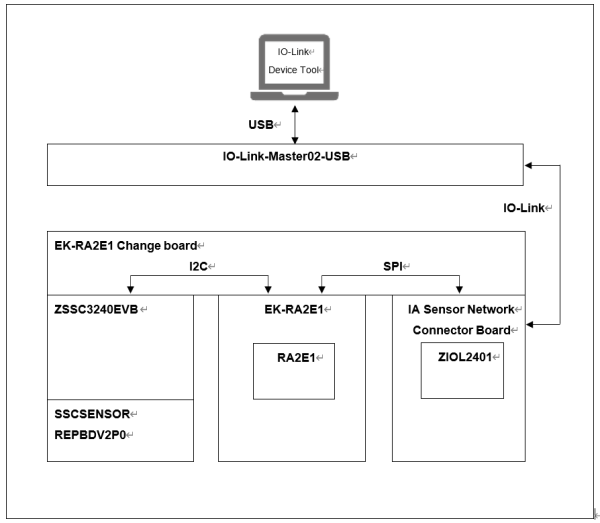

- RA2E1 and IO-Link Line Driver (PHY) communicate sensing data and system status through SPI

- IO-Link Slave and IO-Link master communicate periodically or each event

- Through IO-Link GUI tool, user can monitor the result of the IO-Link communication and update the configuration values to the IO-Link device.

- Solution key features

- System size saving: RA2E1 supports Chip Scale Package (CSP) reduce PCB size to fit to high-density systems

- Easy sensing: Renesas’s ZSSC3240 (Sensor Signal Conditioner) and ZIOL2401 IO-Link PHY realize easy Analog development through dedicated GUI tools

- Time saving: Sample code and evaluation stack save the time to set up evaluation environment.

In addition, Renesas can offer a scalable lineup for IO-Link Line Drivers, for a wide range of specifications to meet your needs, including communication interfaces with microcontrollers, protection functions, LDOs, and package sizes.

To achieve the Digital Transformation of smart manufacturing by IO-Link, Renesas is willing to support customers together with our reliable partners who offer market-trusted comprehensive solutions. Please refer to the following for more information on our IO-Link Device Applications, Industrial Ethernet & Fieldbus, and Factory Automation.