Environmental Activities

Environmental Initiatives | Environmental Protection Goals | Climate Change Initiatives | Conserving Water | Waste Reduction Efforts | Chemical Substance Use | Eco-Product Initiatives | Eco-Communication Initiatives | Biodiversity Conservation Activities | Environmental Data and Third-Party Verification

Climate Change Initiatives –

Our Commitment to Carbon Neutrality

Renesas Aims to Become Carbon Neutral by 2050 to Minimize the Impact of Climate Change

As an interim target, we have set a goal for 2030 to reduce greenhouse gas emissions from business activities (Scope1 and 2) by 38% compared to 2021 levels. This is in line with the 1.5°C target (an effort to limit the increase in global average temperature to 1.5°C compared to pre-industrial revolution levels) instead of the previous 2.0°C target. We are committed to having 70% of our suppliers by emissions covering Cat1 set science-based targets by 2026 (Scope3).

We plan to achieve our goal by reducing the emission of PFC gas – a greenhouse gas that heavily impacts the environment – and meeting the domestic electrical and electronics industry targets in Japan and the energy intensity reduction target in accordance with the Energy Conservation Law. These initiatives also include expanding the use of reusable energy at our manufacturing sites which consume significant amounts of energy.

In August 2022, the Science-Based Target initiative (SBTi) certified our mid-term targets (announced on August 25, 2022).

Response to the TCFD Proposal

Renesas has signed up to support the Task Force on Climate-related Financial Disclosure (TCFD) and joined the Japan-based TCFD Consortium. As a way to demonstrate our support for TCFD recommendations, we have been examining the risks and opportunities that climate change poses to our business, and proactively disclosing information to stakeholders based on the TCFD framework.

Environmental Impact of the Entire Value Chain

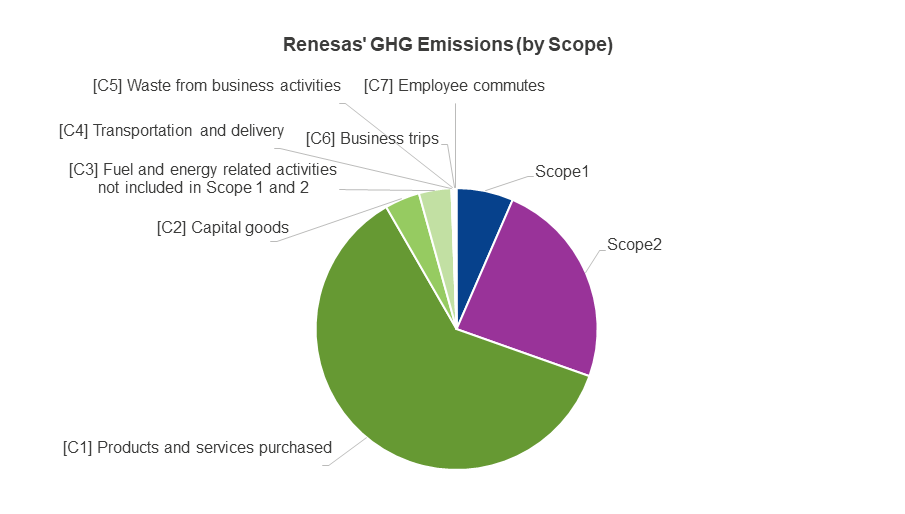

In order to understand the environmental impact of our business activities including the value chain, we have calculated the amount of greenhouse gas (GHG) emission from scope 1 through 3 based on the GHG protocol.

| FY2022 | Classification | Range and Calculation Method | Emission amount (t-CO2) | Ratio |

|---|---|---|---|---|

| Scope1 | Direct emission of greenhouse gases | Greenhouse gases emitted by Renesas | 196,261 | 6.53% |

| Emission of PFC gases | 157,510 | - | ||

| Scope2 | Indirect emission from the use of electricity, heat and steam | Indirect emission following the use of electricity and gases provided by other companies | 717,422* | 23.86% |

| Scope3 | [C1] Purchased goods and services | Emission following procurement of materials and production outsourcing | 1,842,705 | 61.29% |

| [C2] Capital goods | Emission following the increase of production equipment | 120,942 | 4.02% | |

| [C3] Fuel- and energy-related activities not included in Scope1 and 2 | Emissions from upstream processes of procured electricity and fuel | 112,074 | 3.73% | |

| [C4] Upstream transportation and delivery | Emissions from production logistics within Japan | 428 | 0.01% | |

| [C5] Waste generated by operation | Emissions from transportation and disposal of waste conducted by another party | 6,843 | 0.23% | |

| [C6] Business travel | Emissions from employee business trips | 6,823 | 0.23% | |

| [C7] Employee commuting | Emissions from employee commutes in Japan | 3,272 | 0.11% | |

| [C8] Upstream leased assets | Not applicable (included in Category 1) | 0 | 0.00% | |

| [C9] Downstream transportation and delivery | Not applicable | - | - | |

| [C10] Processing of sold products | Not applicable | - | - | |

| [C11] Use of products sold | Not applicable | - | - | |

| [C12] Disposal of sold products | Not applicable | - | - | |

|

[C13] Downstream leased assets |

Not applicable | 0 | 0.00% | |

| [C14] Franchises | Not applicable | 0 | 0.00% | |

| [C15] Investments | Not applicable | 0 | 0.00% | |

| Total | 3,006,770* | 100.0% | ||

In order to calculate CO2 emission level calculation in relation to electricity, we have used the factor provided by the "List of Calculation Methods/ Emission Factors in the Calculation, Report and Publication System" of the Ministry of the Environment and the Ministry of Economy, Trade and Industry of Japan, adjusted conversion factors for individual power businesses based on the Act on Promotion of Global Warming Countermeasures. For figures that represent outside of Japan, the latest values for the each fiscal year supplied by power supply companies. When the CO2 emission levels are uncertain, we use the conversion factors of previous year. For the CO2 emission factor for gas and fuel at the time of calculation, we used the factor provided by the "List of Calculation Methods/ Emission Factors in the Calculation, Report and Publication System" of the Ministry of the Environment and the Ministry of Economy, Trade and Industry of Japan.

* Figures were revised on July 1, 2023. Please refer to the Editing Policies for details.

Eco-Factory Initiatives

We are running several eco-factory initiatives, mainly in the form of reducing our manufacturing sites’ environmental impact, especially those which consume the most energy.

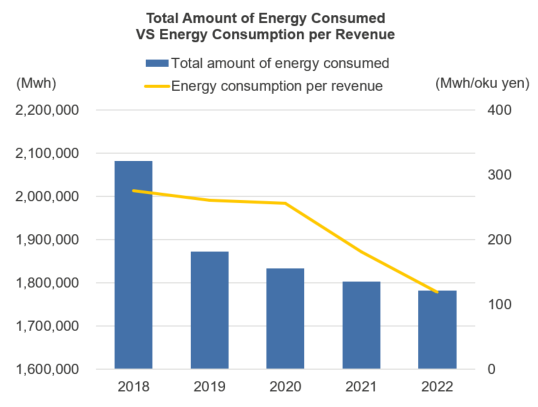

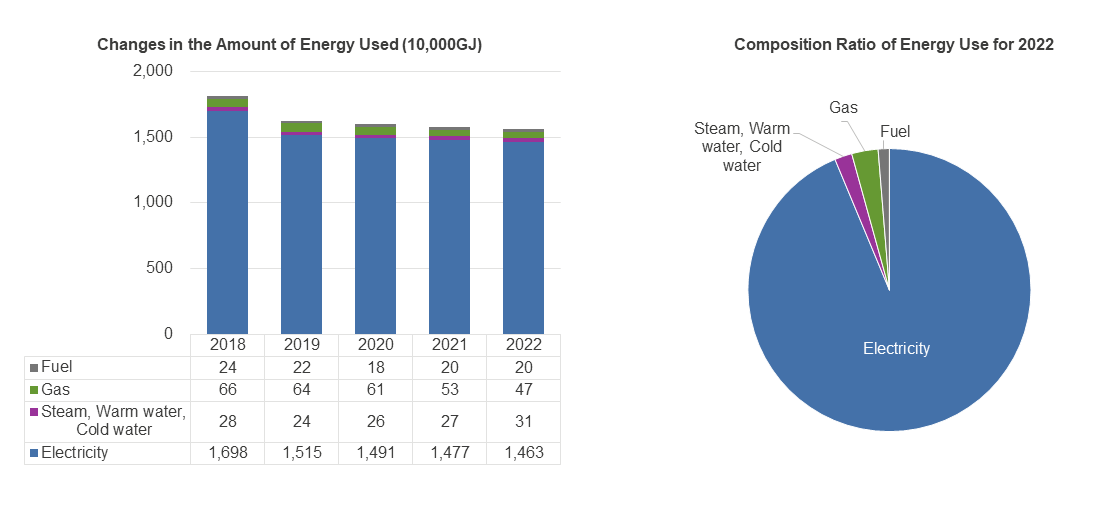

Energy Reduction Results in 2022

In 2022, we reduced energy consumption by 1.2% compared to the previous year of 2021. Energy intensity against revenue decreased by 35% in comparison to the previous year of 2021 due to our significant increase in sales (denominator) driven by continuously strong demand for semiconductors. We were able to reduce the total energy consumption during robust production base operation thanks to the energy-saving measures implemented at each factory and the result of diligent energy management.

In 2023, we will continue to promote energy-saving measures and strive for efficient use of energy corresponding to the Group’s business activities in order to reduce energy consumption and prevent global warming.

In addition, every year, Renesas aims to reduce energy consumption in Japan, which accounts for approximately 80% of the energy consumption of Renesas as a whole, by 1% or more per unit (5-year average), this is in line with the Energy Conservation Law's effort targets. As part of our energy reduction activities to achieve the goal, we have participated in the “Low Carbon Society Action Plan”, an initiative undertaken by the Japanese electrical and electronics industry since 2013. This plan aims for the development of innovative technology which will contribute to the prevention of global warming, promoting international contributions though the transfer of technology, strengthening the cooperation among supply chains.

Main Measures to Reduce Energy Consumption

In line with the Energy Saving Act, we are working to reduce energy consumption by at least 1% per year over a five-year period. Specifically, we are systematically implementing measures such as improving the efficiency of equipment, inverter control, and measures related to natural and vaporization energy. In addition, we are optimizing factory operations in line with production volume changes.

| No. | Items | Details |

|---|---|---|

| 1 | Enhancement of Equipment Efficiency | Refrigerator replacement, optimal control Compressor replacement, machine number control Boiler replacement Dry pump replacement |

| 2 | Motor Inverter Control (Rotation Control) | Air-conditioner fan, various pumps |

| 3 | Natural Energy Reuse of Energy Vaporization Energy, etc. |

Winter-free cooling Waste heat recovery and reuse Water spray humidification |

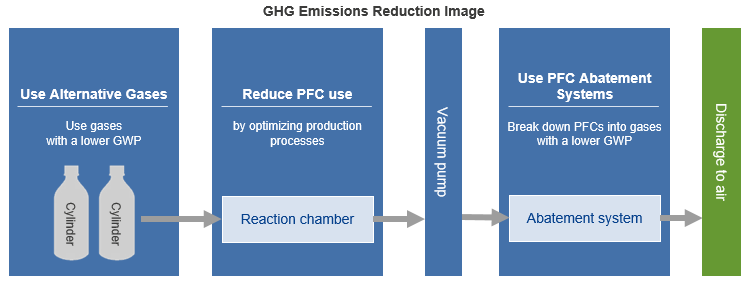

Reduction of Greenhouse Gas Emissions

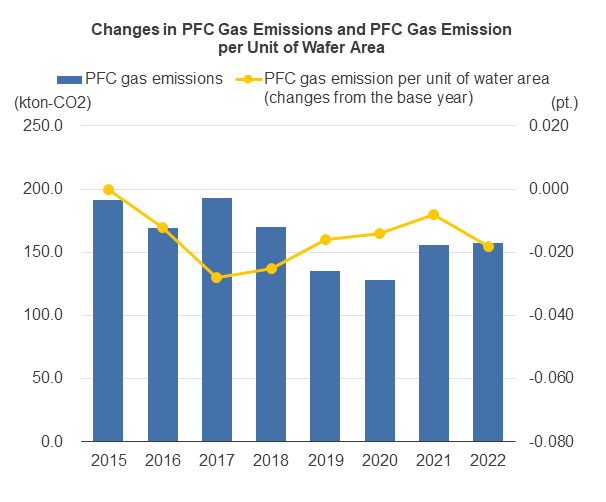

Renesas mainly uses Perfluoro Compound (Note 1) gas, one of the greenhouse gases, as a process gas for plasma etching and wafer cleaning, and as a cleaning gas for reaction chambers in the semiconductor manufacturing process. These gases are not easily decomposed, and their global warming potential (Note 2) is high, ranging from about 7,000 to more than 20,000. Therefore, the reduction of these emissions is important, and we are actively working to prevent global warming by setting targets for reducing PFC gas emissions. Methods to reduce greenhouse gas emissions from PFC gas include 1) changing to smaller GWP gases, 2) reducing PFC gas usage by optimizing processes, and 3) installing detoxification equipment to decompose PFC gases. By combining these three methods, our group has been developing technologies to reduce its emissions target to 90% of the 1995 emission level or lower by 2010. Since 2010 we have continued our reduction efforts, despite structural reforms, and made a large reduction in 2015 where emissions were approximately 20% lower than the 1995 emission levels.

Now that the structural reforms have been completed and we have entered into a growth phase, in 2022, compared to 2015, we achieved a 0.018 percentage point reduction in wafer area per unit of production and approximately 18% reduction in total emissions. Efforts will continue to be made to further reduce emissions beyond 2023.

Note 1: PFC; The semiconductor industry has declared emission reductions for CHF3, CF4, C2F6, C3F8, C4F8, SF6 and NF3

Note 2: GWP; a coefficient indicating how much a given mass of greenhouse gas is estimated to contribute to global warming (CO²=1)

| PFC gas | GWP | |

|---|---|---|

| Perfluorocarbon (PFC) | CF4 | 7,390 |

| C2F6 | 12,200 | |

| C3F8 | 8,830 | |

| C4F8 | 10,300 | |

| Hydrofluorocarbon (HFC) | CHF3 | 14,800 |

| Sulfur hexafluoride (SF6) | 22,800 | |

| Nitrogen trifluoride (NF3) | 17,200 | |

Seven PFC gases subject to reduction in the semiconductor industry and Global Warming Potential (GWP) (Note 3)

Note 3: 2006 IPCC Guidelines (IPCC: Intergovernmental Panel on Climate Change)

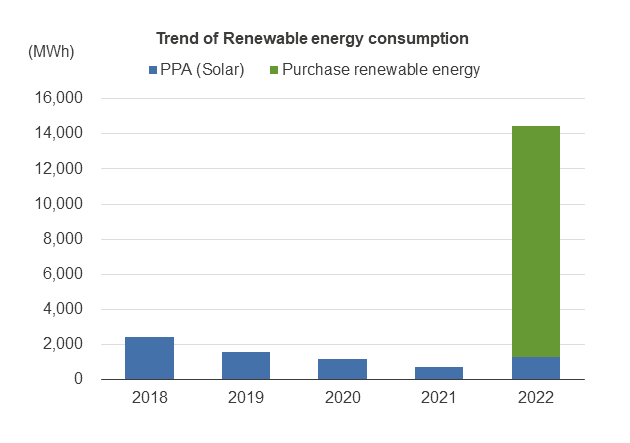

Renewable Energy Installation

Renesas is expanding the installation of renewable energy, mainly at its production sites, to achieve its greenhouse gas reduction targets.

In Japan, we have started purchasing green electricity in 2022. We are also installing solar panels (PPA) overseas and began the operation at a production base in China and Malaysia second half of this year.

Overview of solar panel (PPA) installation bases

| Production base | Renesas Semiconductor (Beijing) Co., Ltd. |

| Country | China |

| System | Solar power PPA |

| Power generation amount | 283kwh/h |

| Operation start | October 2013 |

| Production base | Renesas Semiconductor (Suzhou) Co., Ltd. |

| Country | China |

| System | Solar power PPA |

| Power generation amount | 178kwh/h |

| Operation start | October 2022 |

| Production base | Renesas Semiconductor KL Sdn. Bhd. |

| Country | Malaysia |

| System | Solar power PPA |

| Power generation amount | 137kwh/h |

| Operation start | December 2022 |

Environmental Measures in Logistics Operations

In Japan we engage in logistics-related environmental activities (such as energy reduction for product and waste transportation, and the reduction and reuse of packaging materials).

In Japan, there are recommendations to reduce energy intensity against revenue under the Energy Conservation Law, and therefore all of our Japanese affiliates promote the reduction of transportation related CO² emissions.

In 2022, in comparison to the previous year, we reduced the product related transportation by 330,000 ton kilometers and waste related transportation increased 50,000 ton kilometers. We also recorded 4,290,000 ton kilometers for the overall transport volume within Japan, a decrease of 280,000 ton kilometers from the previous year. We will continue our efforts to reduce transportation energy in 2023.

| Fiscal Year | Transport Volume (10,000 ton-kilometers) | ||

|---|---|---|---|

| Product logistics | Waste logistics | Total (Japan) | |

| 2022 | 212 | 217 | 429 |

| 2021 | 245 | 212 | 457 |

| 2020 | 380 | 185 | 565 |

| 2019 | 495 | 186 | 681 |

| 2018 | 533 | 191 | 724 |

Tree Planting Initiative to Address Climate Change

In an effort to realize our aspiration to grow further as a sustainable company and become a company that gives something back to society, we made a donation to the international NGO Oxfam that supports global reforestation activities, embarking the planting of 20,000 trees worldwide in 2020, 20,000 being the number of employees at Renesas at that time.

We will continue to support and implement global climate change initiatives in the future.

Contributing to SDGs

Renesas’ efforts in Climate Change Initiatives contributes to these Sustainable Development Goals targets:

7.2 By 2030, increase substantially the share of renewable energy in the global energy mix

9.4 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally-sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities

13.3 Improve education, awareness-raising and human and institutional capacity on climate change mitigation, adaptation, impact reduction and early warning

Environmental Activities

Environmental Initiatives | Environmental Protection Goals | Climate Change Initiatives | Conserving Water | Waste Reduction Efforts | Chemical Substance Use | Eco-Product Initiatives | Eco-Communication Initiatives | Biodiversity Conservation Activities | Environmental Data and Third-Party Verification